Xebec Deburring Tools Save You Money by:

Increasing Productivity

Innovative tools for a wide range of manufacturing processes & products that decrease your processing time and increase your throughput.

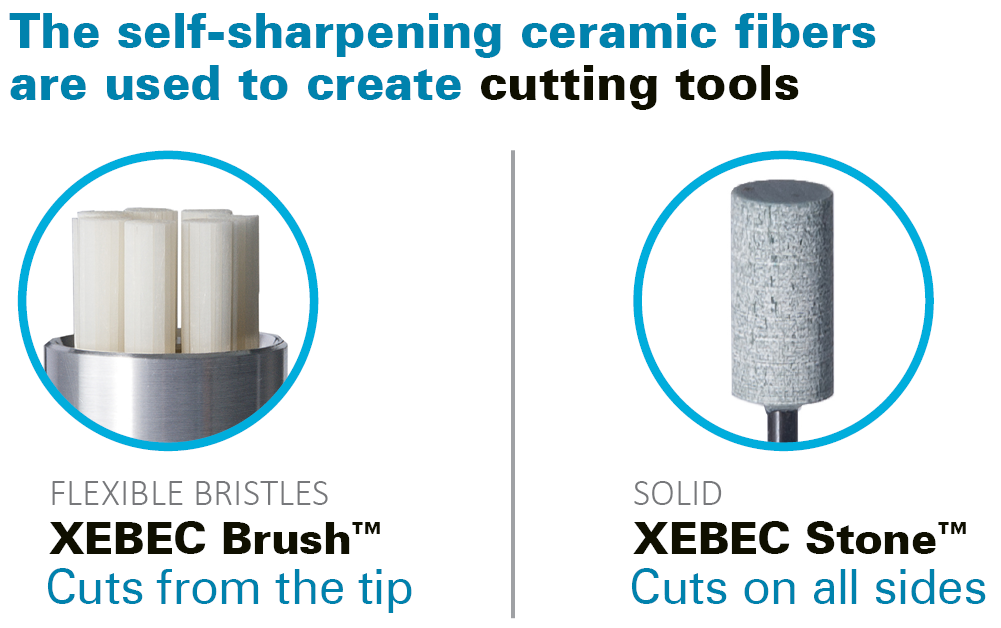

The Xebec Difference

What makes XEBEC® deburring tools so unique?

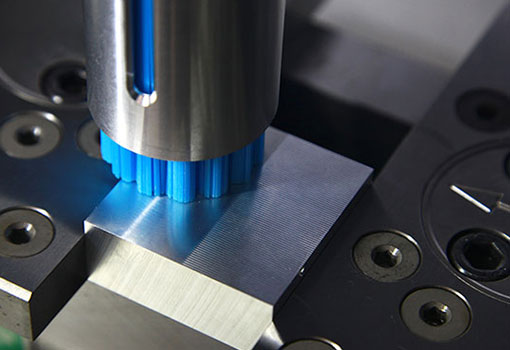

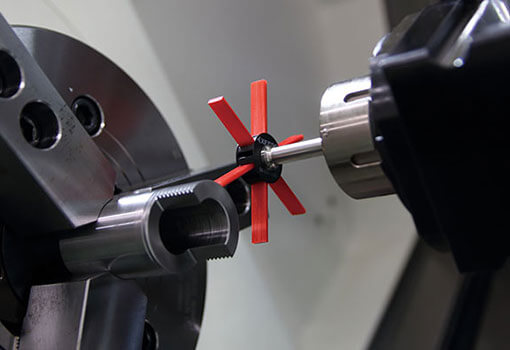

Xebec Technology’s ceramic fiber products utilize a unique, patented process to produce brushes, sticks and stones that significantly outperform other technologies in CNC machines. The back burr cutter and path incorporate a unique cutting tool geometry with a customized path program to maximize cutting efficiency and tool life.

How Do I Know Which Deburring Method is Right for My Application?

Xebec Blows Away Nylon Brushes for CNC Deburring

Back Burr Cutter Speed Demonstration

Learn how much faster Xebec Back Burr Cutter with Xebec Path is than other cutting tools

Target Markets

Our focus is identifying and offering value added deburring and surface finishing solutions for machined parts. We have demonstrated particular success in the following market segments as well as other machined parts.

Learn more about successful applications, case studies and industry specific success stories here

Visit Our Virtual Exhibition Booth

Learn more how Xebec tools can solve your most challenging deburring and surface finishing issues.

Product Selection Guide

Information to help select the right product for your deburring and surface finishing needs.

Review Our Complete Offering of Deburring & Finishing Tools

Features, process conditions, maintenance, guaranteed test policy, FAQs and more

What is the Cost of Xebec Products?

Total Cost considerations, expected Xebec product life, List Price file

Have Technical Questions?

Get technical info including 3D files (STEP, DXF) product prints, starting operating parameters, safety instructions and more.

Xebec Deburring Tools Explained: Cost, Benefits & FAQs Answered by Experts

Get answers to the 26 most common questions about Xebec.