Products

XEBEC Burrless Chamfering Cutter

XEBEC Burrless Chamfering Cutter

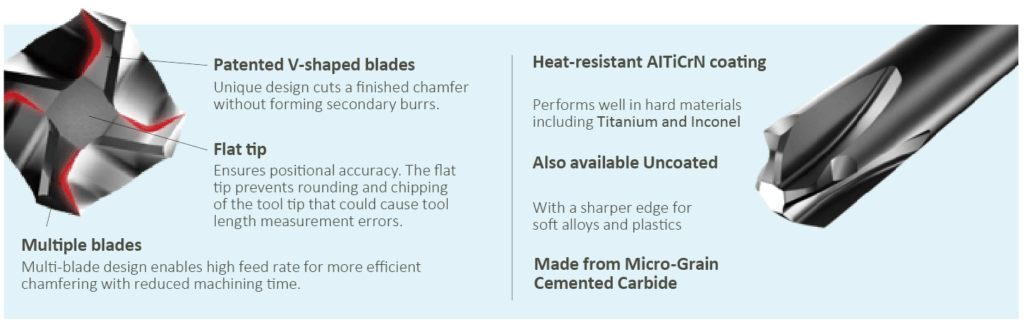

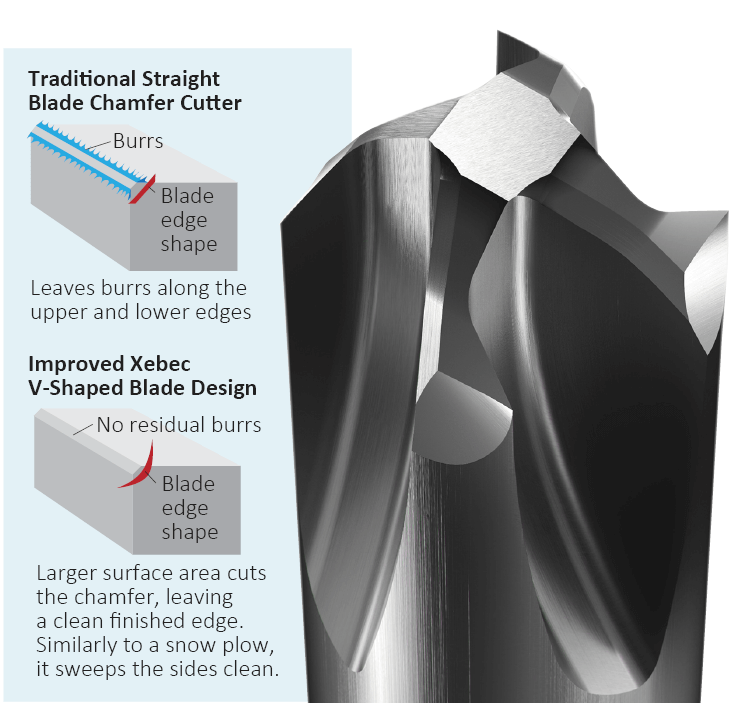

BurrlessChamfering® provides an exact chamfer without secondary burrs, eliminating the time and cost of deburring.

- BurrlessChamfering® with a patented, multi-blade, V-shaped design

- Cuts a clean, finished, burr-free chamfer

- Made from Micro-Grain Cemented Carbide

- Available Coated with a heat-resistant AITiCrN coating for steel, stainless steel, cast iron, titanium, nickel and heat resistant alloys or Uncoated with a sharper edge that’s perfect for soft aluminum alloys, resins and plastics

AlTiCrN Coated Cutters

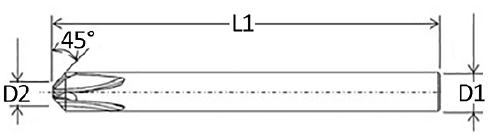

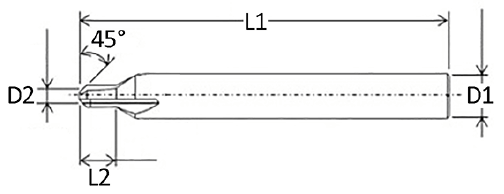

Tool Dimensions Shown: Metric

Inch

EDP

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

No. Blades

Target Chamfer Size (mm)

Cutting Angle

Max DOC (mm)

Product Number

60020

6

2

50

5

3

0.3 - 0.6

45

1

XC-C-03-M

60021

6

4

60

4

0.7 - 1.5

45

2

XC-C-06-M

EDP

D1 Shank Diameter (in)

D2 Neck Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

No. Blades

Target Chamfer Size (in)

Cutting Angle

Max DOC (in)

Product Number

60020

0.236

0.079

1.969

0.197

3

0.012 - 0.024

45

0.039

XC-C-03-M

60021

0.236

0.157

2.362

4

0.024 - 0.059

45

0.079

XC-C-06-M

Uncoated Cutters

Tool Dimensions Shown: Metric

Inch

EDP

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

No. Blades

Target Chamfer Size (mm)

Cutting Angle

Max DOC (mm)

Product Number

60022

6

2

50

5

3

0.3 - 0.6

45

1

XC-C-03-N

60023

6

4

60

4

0.7 - 1.5

45

2

XC-C-06-N

EDP

D1 Shank Diameter (in)

D2 Neck Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

No. Blades

Target Chamfer Size (in)

Cutting Angle

Max DOC (in)

Product Number

60022

0.236

0.079

1.969

0.197

3

0.012 - 0.024

45

0.039

XC-C-03-N

60023

0.236

0.157

2.362

4

0.024 - 0.059

45

0.079

XC-C-06-N

Features

- The flat tip prevents rounding and chipping of the tool tip that could cause tool length measurement errors.

- Multi-blade design enables high feed rate for more efficient chamfering with reduced machining time.

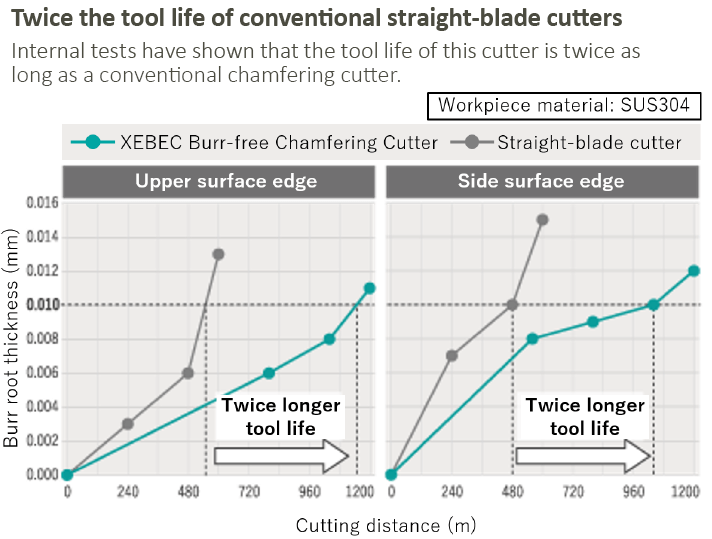

Twice the tool life of conventional straight-blade cutters

Internal tests have shown that the tool life of this cutter is twice as long as a conventional chamfering cutter.

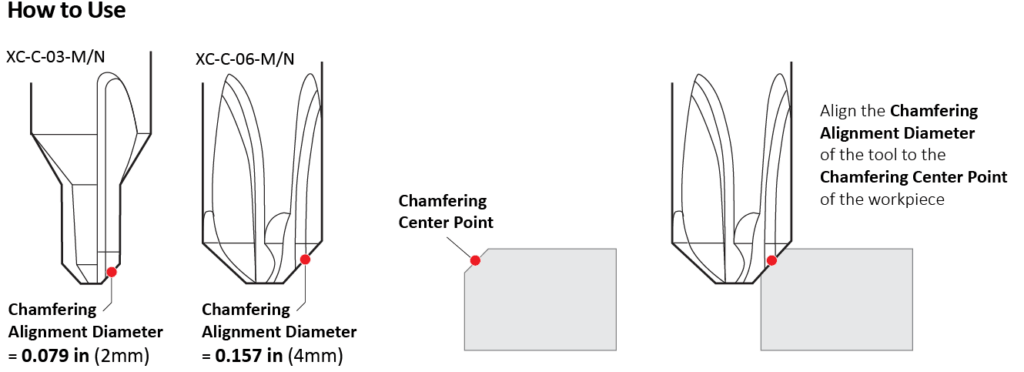

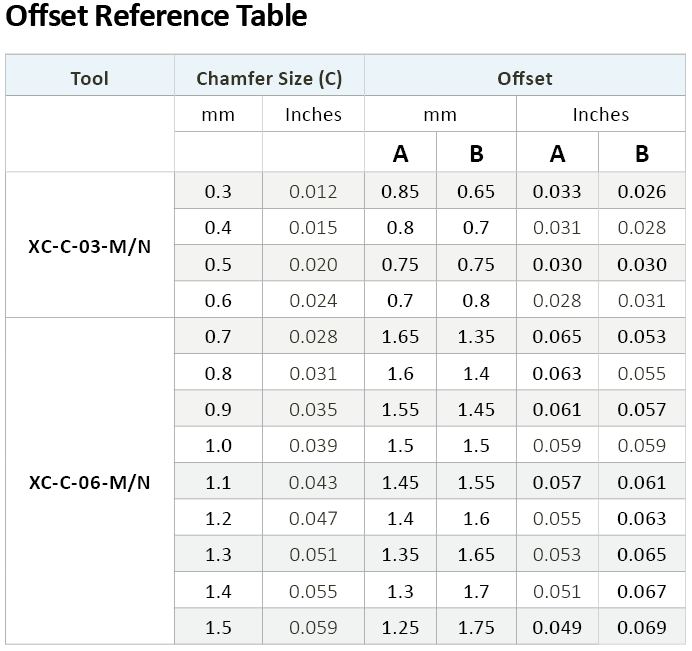

How to Use

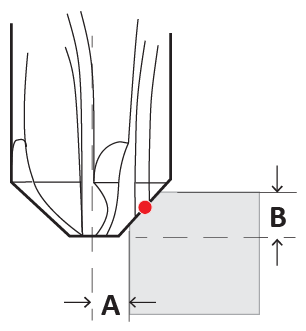

Create the machining program by referring to the offsets A and B in the table for desired chamfer size. This ensures that chamfer alignment diameter and the chamfer center point are aligned properly.

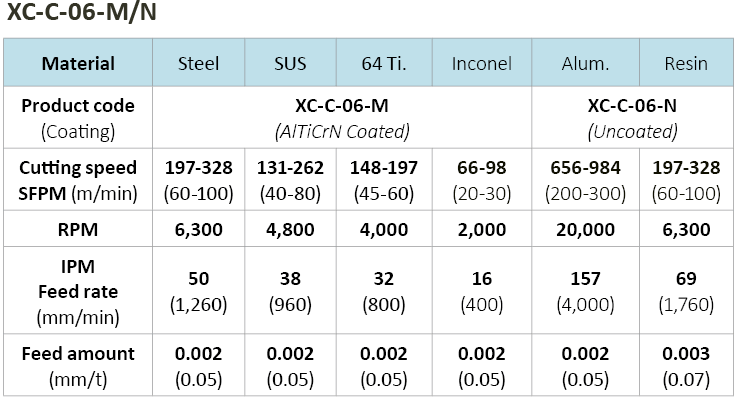

Machining Conditions

- Rotational speed and feed rates are a guide for initial machining under standard machining conditions.

- To improve the chamfering quality, please adjust the rotational speed, feed rate and the depth of cut.

- If vibration or abnormal noise occurs, lower the rotational speed and feed rate, or adjust the depth of cut to be smaller.

- If burrs are formed when chamfering a resin workpiece, please maintain the feed rate of 0.07 (mm/t) and adjust the rotational speed in accordance with the rotational speed of the currently used tool.

Starting Operating Parameters

Under standard machining conditions.