Products

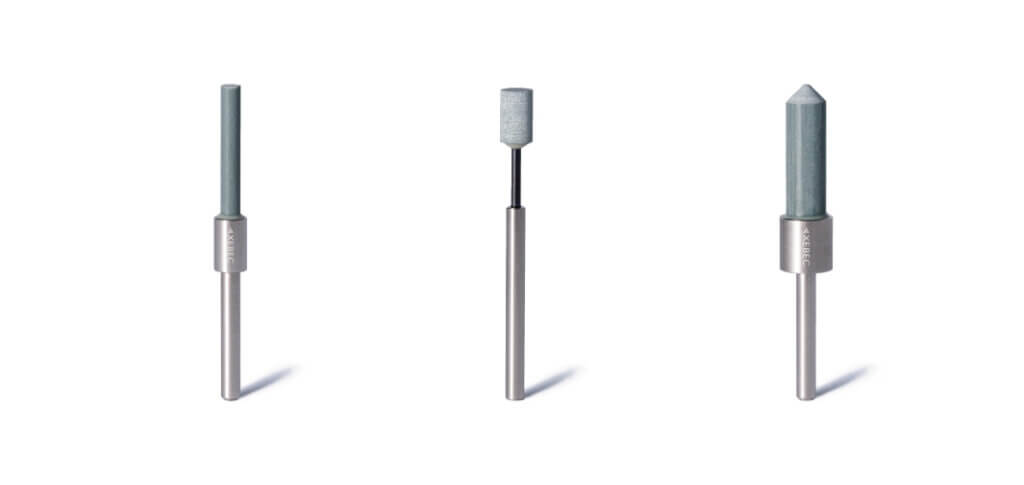

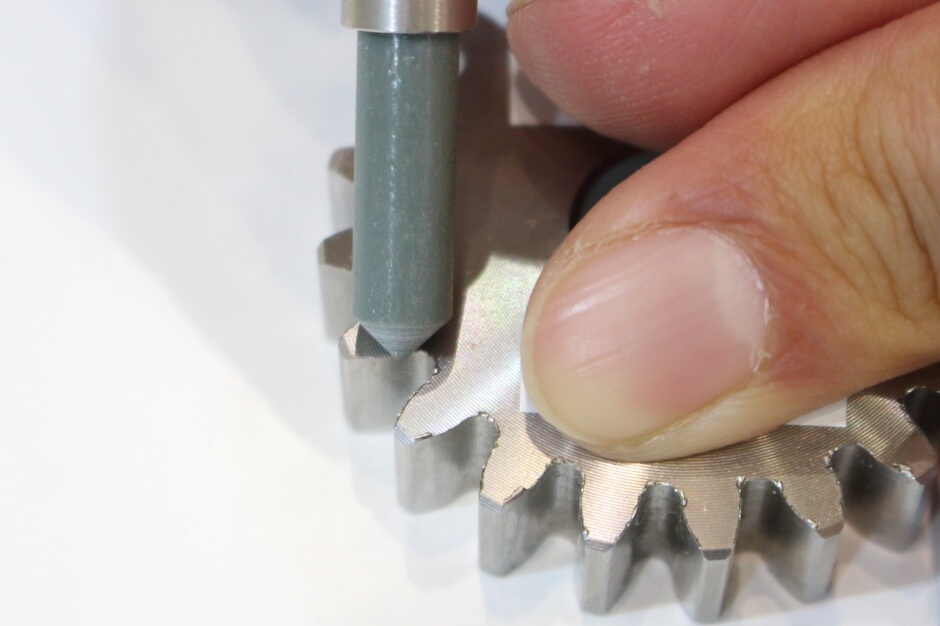

XEBEC Stone™ Mounted Point

XEBEC Stone™ Mounted Point

Perfect for use with pneumatic tools at high rotational speed. Cutting edges exposed across the entire surface.

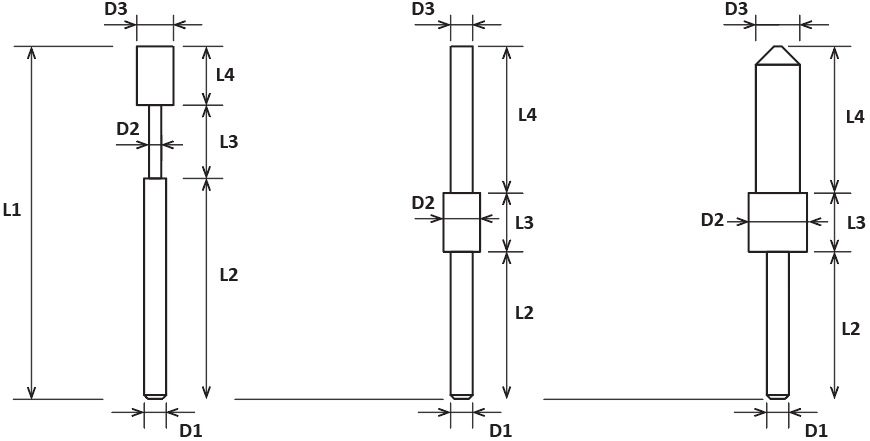

Tool Dimensions Shown: Metric

Inch

Head

EDP

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

D3 Stone Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

L3 Neck Length (mm)

L4 Stone Length (mm)

Max RPM

Product Number

List Price

- Cylinder Shaft

60003

3

1.5

5

48

30

10

8

30,000

AX-PM-5RF

$50.55

- Solid Cylinder

60004

3

5

3

48

20

8

20

60,000

AX-PM-3R

$37.92

- Pointed Tip

60005

3

8

6

48

20

8

20

60,000

AX-PM-6T

$60.65

Head

EDP

D1 Shank Diameter (in)

D2 Neck Diameter (in)

D3 Stone Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

L3 Neck Length (in)

L4 Stone Length (in)

Max RPM

Product Number

List Price

- Cylinder Shaft

60003

0.118

0.059

0.197

1.89

1.181

0.394

0.315

30,000

AX-PM-5RF

$50.55

- Solid Cylinder

60004

0.118

0.197

0.118

1.89

0.787

0.315

0.787

60,000

AX-PM-3R

$37.92

- Pointed Tip

60005

0.118

0.315

0.236

1.89

0.787

0.315

0.787

60,000

AX-PM-6T

$60.65

How to Select

AX-PM-3R is suitable for narrow parts.

AX-PM-5RF uses flexible shaft, which allows soft contact with a workpiece.

AX-PM-6T is suitable large parts.

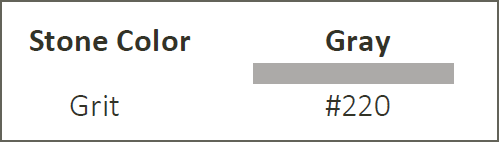

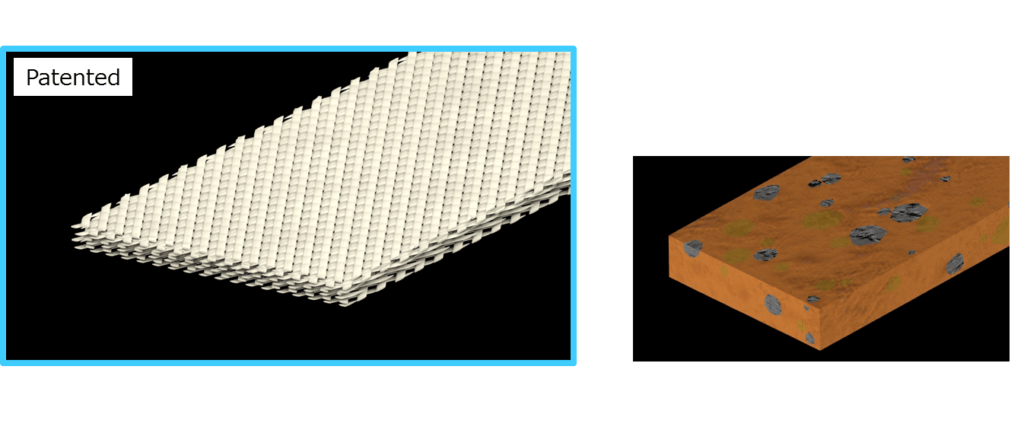

Strucutre of Xebec Stone™

XEBEC Stone™ uses the original abrasive ceramic fiber material instead of abrasive grains. By using ceramic stone on the head portion, the cutting edges are exposed over the entire surface. This tool prevents clogs and scratches to the surface because it does not contain abrasive grains.

How to Use

XEBEC Stone™ Mounted Point has grinding power on the entire surface of the head portion. It allows deburring in various ways as long as the tip of the head portion contacts with the processing area.

Because it can be rotated at high speed, it can be attached to a pneumatic tool as well as an electric rotating tool.

Truing

If the tool head (ceramic stone) is deformed from use, reshape it by lightly pressing the periphery onto a diamond disc blade while rotating the tool.

You can also customize the shape based on your preference according to the application or workpiece shape.

Operator Safety Measures

For Protective Equipment

Always wear protective goggles, gloves and masks when operating the tool. Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Beware of Grinding Powder

Grinding powder and burrs may scatter within an area around the work as the brush revolves; please stay clear of this area.

Be Aware of Your Surroundings

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter, enclose your working area to prevent other people entering, or have the people surrounding your work area protective equipment as well.

Warning

By not following the above safety measures, you are vulnerable to the following risks:

- A tool or a part of a tool may crack, drop off, distort or break.

- Broken pieces of a tool or grinding dust may stick into your skin and eyes, causing irritation and/or blindness.

- Dust generated by machining process may cause allergic reactions.