Products

XEBEC Brush™ End Type

XEBEC Brush™ End Type

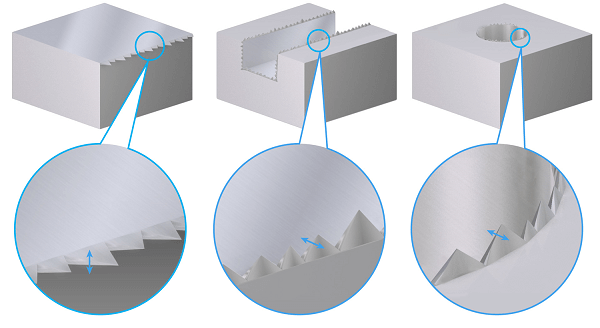

For cutter-mark removal, polishing and finishing of parts with small or narrow features. For use in CNC, robots or hand-held rotary tools.

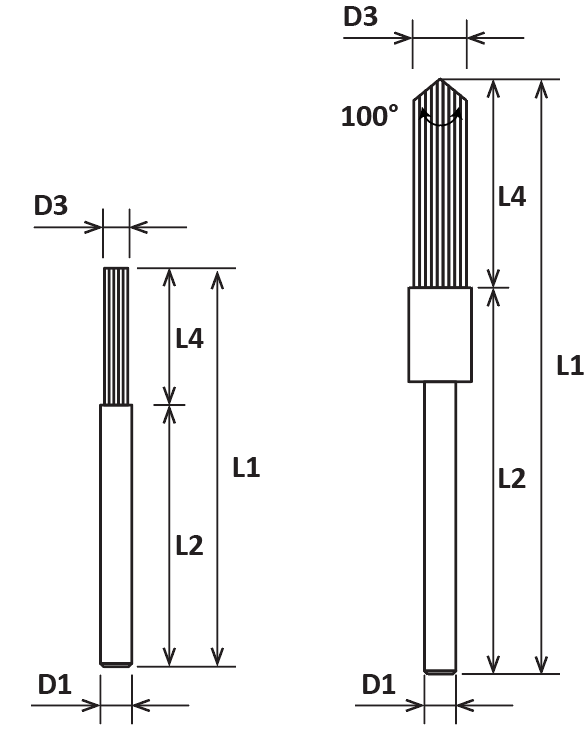

Tool Dimensions Shown: Metric

Inch

Color

EDP

D3 Brush Size (mm)

D1 Shank Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

L4 Brush Length (mm)

Max RPM

Product Number

List Price

Pink

30050

1

3

52

37

15

15,000

A13-EB01S

$15.89

Red

30054

1

3

52

37

15

15,000

A11-EB01S

$15.89

Pink

30051

1.5

3

52

37

15

15,000

A13-EB015S

$18.78

Red

30055

1.5

3

52

37

15

15,000

A11-EB015S

$18.78

Pink

30052

2

3

52

37

15

15,000

A13-EB02S

$24.57

Red

30056

2

3

52

37

15

15,000

A11-EB02S

$24.57

Pink

30053

2.5

3

52

37

15

15,000

A13-EB025S

$31.78

Red

30057

2.5

3

52

37

15

15,000

A11-EB025S

$31.78

Pink

30014

3

3

67

28

30

6,000

A13-EB03M

$51.95

Blue

60012

5

3

57

28

20

12,000

A32-EB06M

$43.72

Red

60001

5

3

57

28

20

12,000

A11-EB06M

$50.02

White

60002

5

3

57

28

20

12,000

A21-EB06M

$50.02

Color

EDP

D3 Brush Size (in)

D1 Shank Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

L4 Brush Length (in)

Max RPM

Product Number

List Price

Pink

30050

0.039

0.118

2.047

1.457

0.591

15,000

A13-EB01S

$15.89

Red

30054

0.039

0.118

2.047

1.457

0.591

15,000

A11-EB01S

$15.89

Pink

30051

0.059

0.118

2.047

1.457

0.591

15,000

A13-EB015S

$18.78

Red

30055

0.059

0.118

2.047

1.457

0.591

15,000

A11-EB015S

$18.78

Pink

30052

0.079

0.118

2.047

1.457

0.591

15,000

A13-EB02S

$24.57

Red

30056

0.079

0.118

2.047

1.457

0.591

15,000

A11-EB02S

$24.57

Pink

30053

0.098

0.118

2.047

1.457

0.591

15,000

A13-EB025S

$31.78

Red

30057

0.098

0.118

2.047

1.457

0.591

15,000

A11-EB025S

$31.78

Pink

30014

0.118

0.118

2.638

1.102

1.181

6,000

A13-EB03M

$51.95

Blue

60012

0.197

0.118

2.244

1.102

0.787

12,000

A32-EB06M

$43.72

Red

60001

0.197

0.118

2.244

1.102

0.787

12,000

A11-EB06M

$50.02

White

60002

0.197

0.118

2.244

1.102

0.787

12,000

A21-EB06M

$50.02

*60001, 60002, 60012 have a 100 degree, angled tip

How to Select

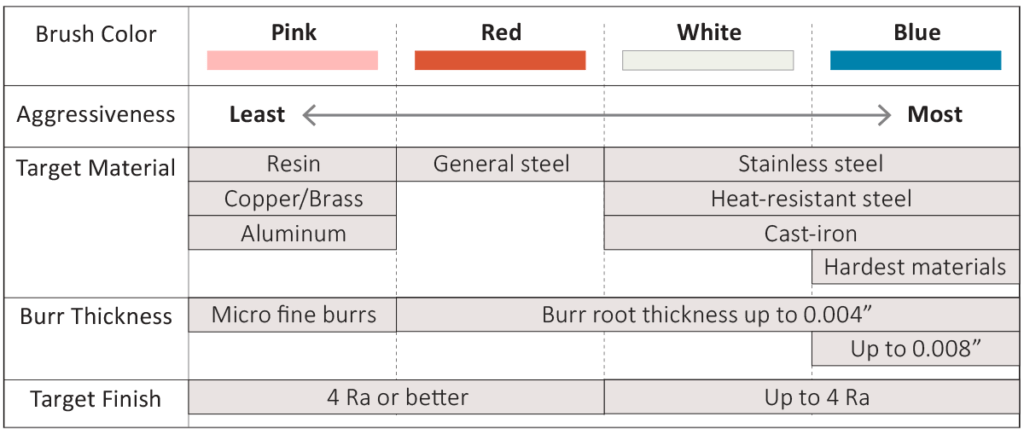

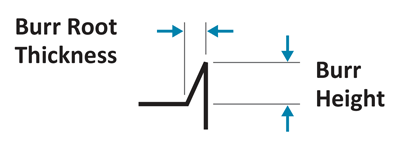

Grinding power differs depending on brush color. All Xebec brushes are made from the same proprietary ceramic fibers manufactured into rods, or bristles, of different thicknesses. The greater the bristle thickness, the more aggressive the cutting action. Refer to the chart below and select brush color based on the workpiece material and burr root thickness.

How to Choose Brush Color

Target Burr Size

Burr Root Thickness of 0.008” or less (Burrs can be bent with a fingernail)

Strucutre of Xebec Ceramic Fiber

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

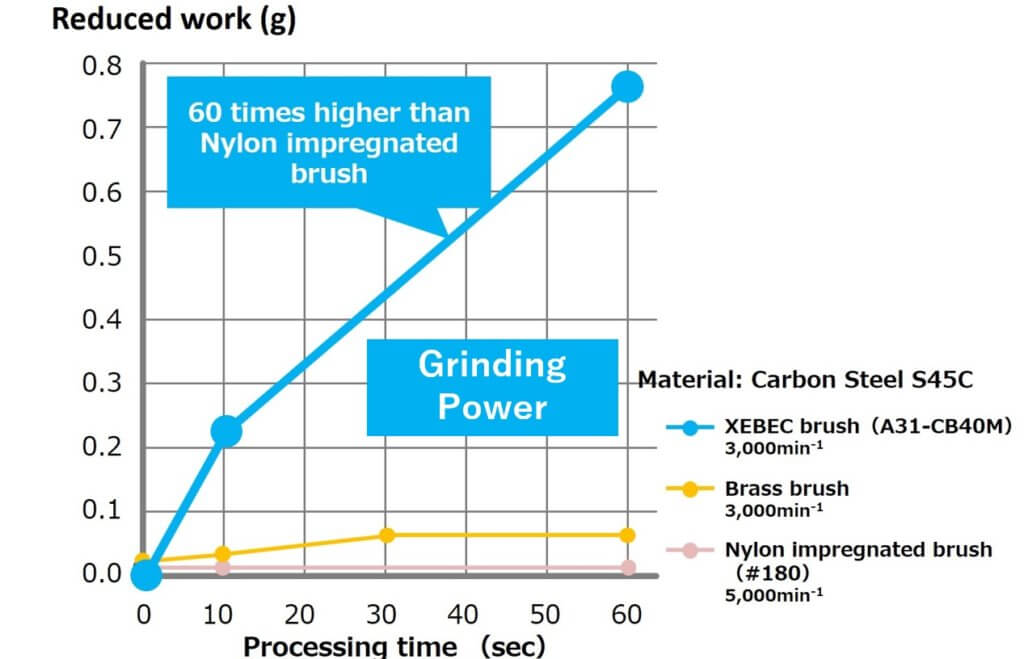

Strength 1: Unsurpassed Grinding Power

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

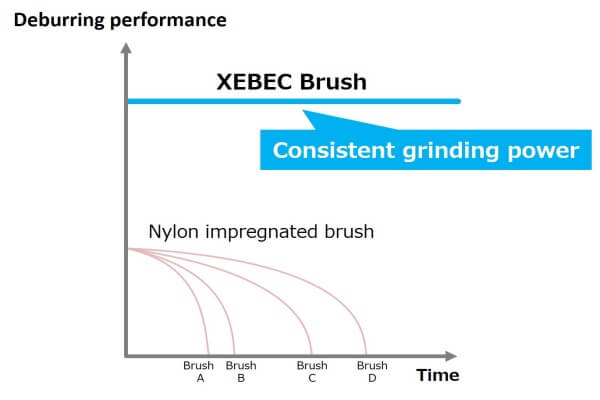

Strength 2: Consistent Grinding Power to the End

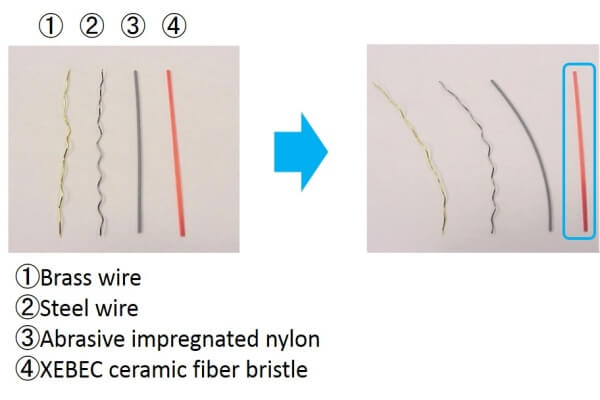

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

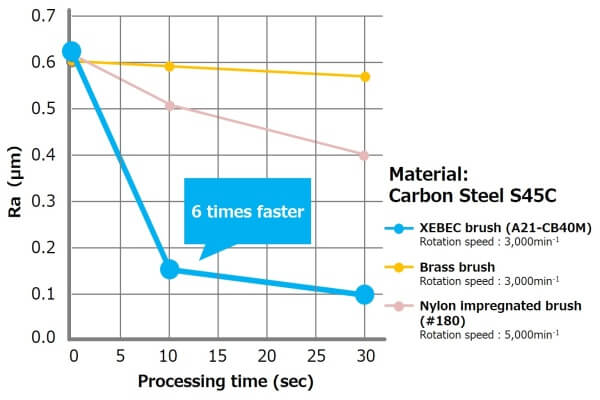

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Truing

When the brush is worn out unevenly, you can form the tip of the brush using a diamond disc blade. Use drilling machine or lathe.

Truing by Drilling Machine

Truing by Lathe

If you want to cut off the brush, cut from the side of the brush using a diamond disc blade and sever it.

Operator Safety Measures

For Protective Equipment

Always wear protective goggles, gloves and masks when operating the tool. Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Beware of Grinding Powder

Grinding powder and burrs may scatter within an area around the work as the brush revolves; please stay clear of this area.

Be Aware of Your Surroundings

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter, enclose your working area to prevent other people entering, or have the people surrounding your work area protective equipment as well.

Warning

By not following the above safety measures, you are vulnerable to the following risks:

- A tool or a part of a tool may crack, drop off, distort or break.

- Broken pieces of a tool or grinding dust may stick into your skin and eyes, causing irritation and/or blindness.

- Dust generated by machining process may cause allergic reactions.