Products

XEBEC Brush™ Wheel Type

XEBEC Brush™ Wheel Type

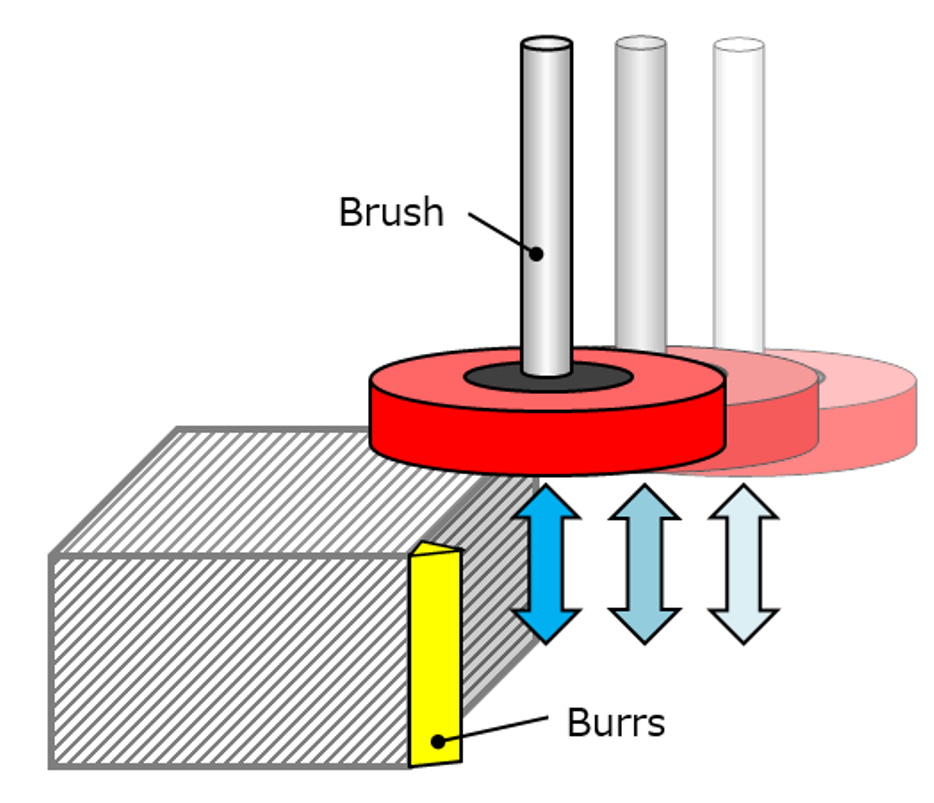

For deburring and polishing of side surfaces and inner diameters in CNC machine. Cutting tips approach from the side.

Note: Brush requires reusable Shank to operate. Sold Separately. Two lengths available, all sizes compatible.

Tool Dimensions Shown: Metric

Inch

EDP

Size

D2 Head Diameter (mm)

D3 Brush Diameter (mm)

L3 Head Thickness (mm)

L4 Brush Height (mm)

Max RPM

Product Number

List Price

60007

50

23

50

9.6

8

3,000

W-A11-50

$213.51

60008

75

23

75

9.6

8

3,000

W-A11-75

$257.12

EDP

Size

D2 Head Diameter (in)

D3 Brush Diameter (in)

L3 Head Thickness (in)

L4 Brush Height (in)

Max RPM

Product Number

List Price

60007

1.969

0.906

1.969

0.378

0.315

3,000

W-A11-50

$213.51

60008

2.953

0.906

2.953

0.378

0.315

3,000

W-A11-75

$257.12

XEBEC Shank for Wheel Brush

Tool Dimensions Shown: Metric

Inch

Shank (mm)

EDP

D1 Shank Diameter (mm)

Product Number

List Price

150 mm Shank

60010

12

WSL

$48.11

70 mm Shank

60009

8

WSM

$43.60

Shank (in)

EDP

D1 Shank Diameter (in)

Product Number

List Price

5.906 in Shank

60010

0.472

WSL

$48.11

2.756 in Shank

60009

0.315

WSM

$43.60

Strucutre of Xebec Ceramic Fiber

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

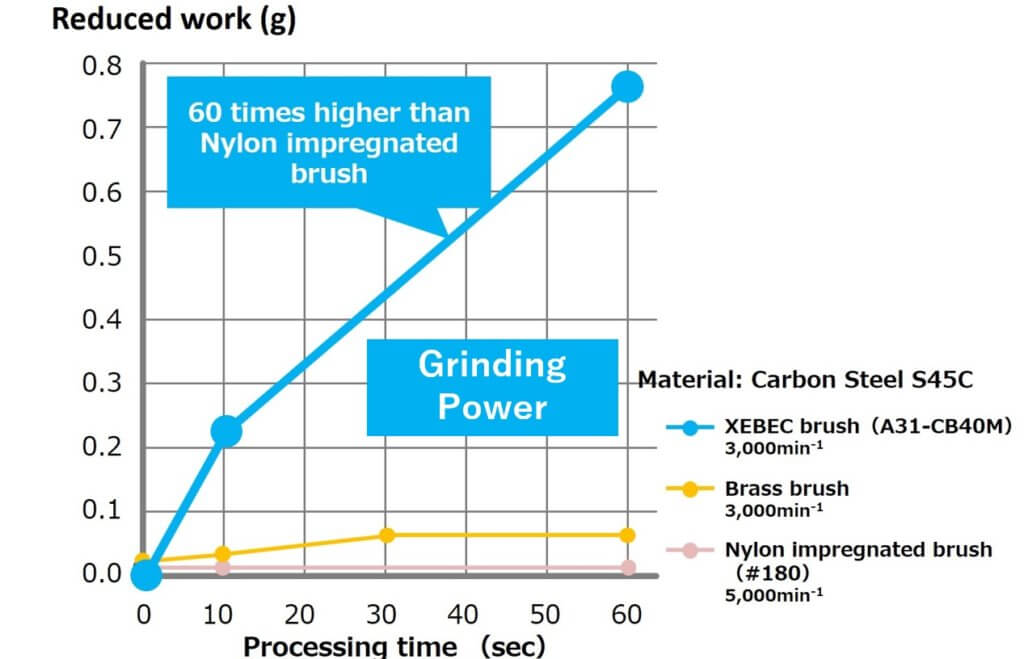

Strength 1: Unsurpassed Grinding Power

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

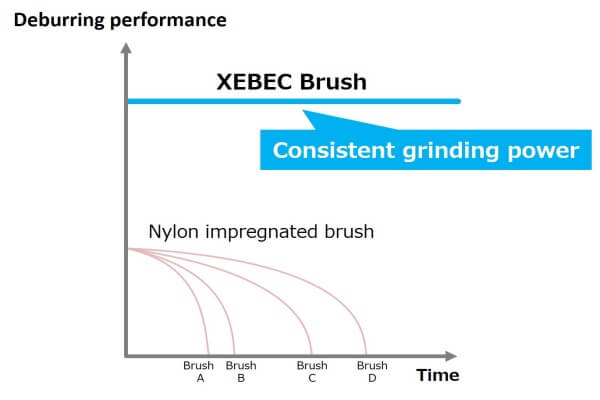

Strength 2: Consistent Grinding Power to the End

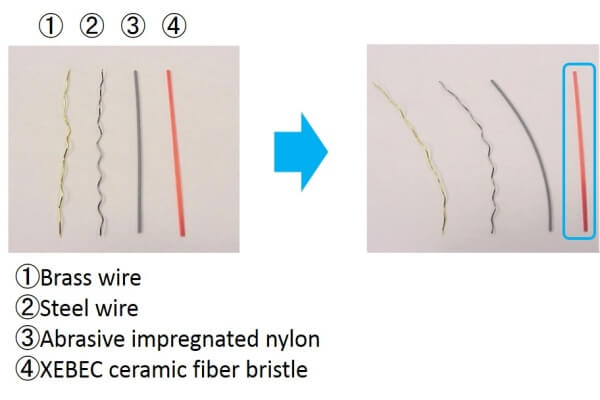

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

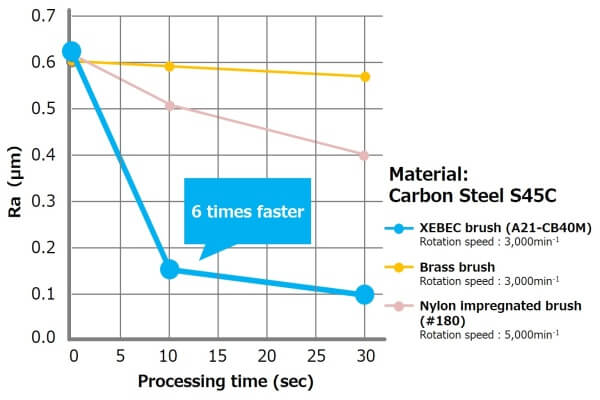

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Applicable Equipment

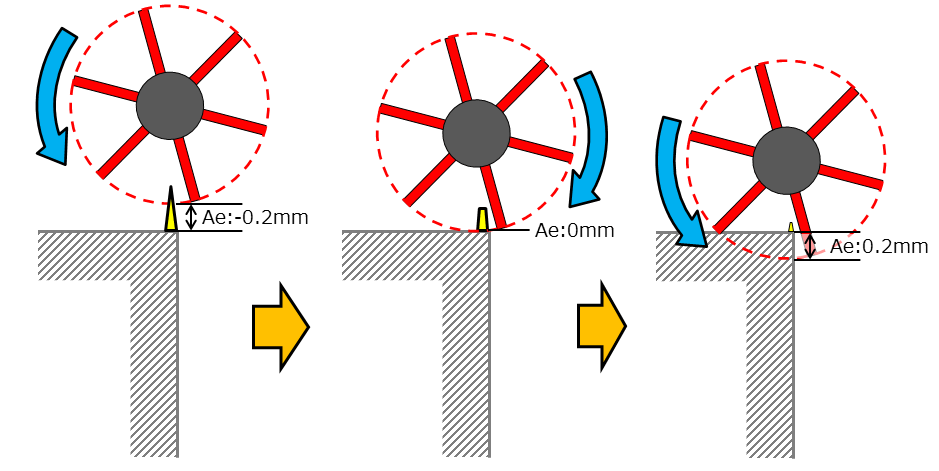

It is necessary to control the spindle speed and the depth of cut to use XEBEC Brush™ Wheel Type.

- Machining center: milling chuck holder, collet chuck holder

- Milling lathe: milling holder for X-axis and Z-axis

- Robot, etc

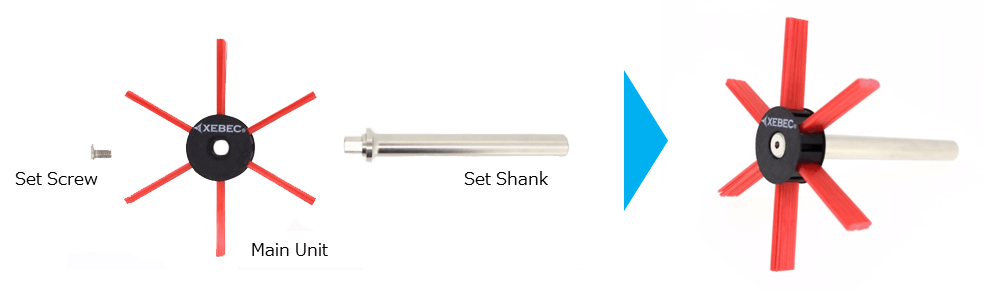

Assembly

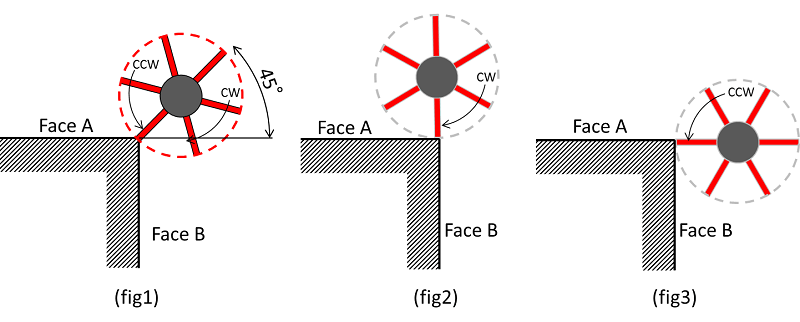

How to Engage

From the top view, the best approach is to place a center of a brush at the center angle to the edge. (Figure 1)

Burrs on Face A and B can be both removed.

Edge quality becomes stable if a brush is rotated in both clockwise and counter-clockwise directions.

Brush position on Figure 2 is effective for burrs on Face A in the same way as Figure 3 for burrs on Face B.

Dry or Wet Machining

The tool can be used for both dry and wet (both oil-based and water-soluble) machining.

Wet machining may improve surface finish quality and too life.

Demo

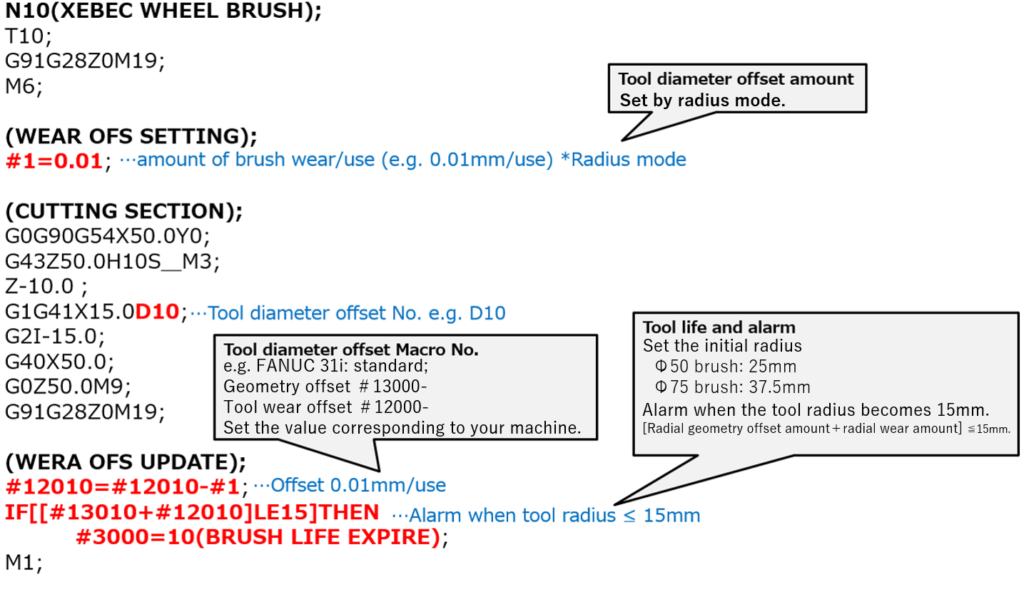

Macro Program

To use the XEBEC Brush™ Wheel Type, the depth of cut must be kept small. It is necessary to offset the wear amount in a radial direction.

Use a macro program or manually offset the wear amount. Refer to the example below.

Initial Process Conditions

Product Code

Cutting Speed (M/MIN)

Spindle Speed (MM/MIN)

Feed Per Bundle (MM/Bundle)

Table Feed (MM/Min)

Depth of Cut (MM)

W-A11-50

250

1600

0.5

4800

0.2

W-A11-75

250

1000

0.5

3000

0.2

Range of Processing Conditions

Product Code

Cutting Speed (M/MIN)

Feed Per Bundle (MM/Bundle)

Table Feed (MM/Min)

Depth of Cut (MM)

W-A11-50

W-A11-75

150 ~ 350

1.5 and under

Less than 1.5*1

3000

*1 As bristles are worn out, bristle length becomes shorter and increases shiftness, causing bristles to be broken. If bristles breakage occurs, decrease the depth of cut.

*The processing conditions differ depending on the state of burrs. Make adjustments according to the quality of the workpiece.

If burrs remain:

- Increase the number of passes

- Then, decrease the feed rate

To extend tool life:

- Increase the feed rate

If burrs are too large:

- Use multiple passes as described below

- Gradually move the brush closer to the bottom of burrs; increase the depth of cut step by step

- Trying to remove burrs in 1 pass may cause excessive tool wear, tool breakage or burrs may not be removed

- Calculate the maximum height of burrs before using the tool