Products

XEBEC Brush™ Crosshole

XEBEC Brush™ Crosshole

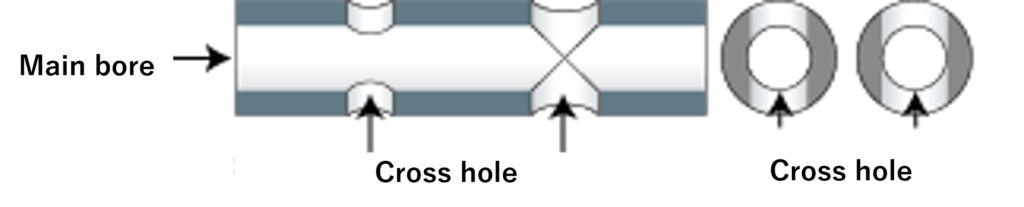

For deburring and polishing of inner wall surfaces of cylinders such as screw and cross holes.

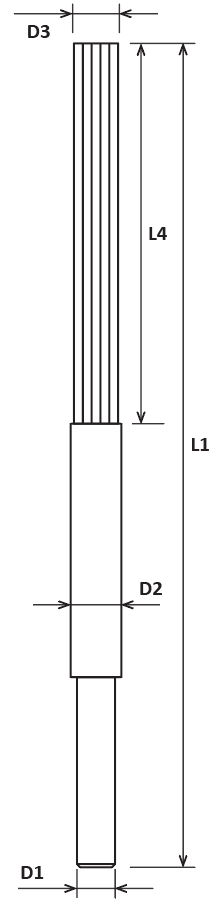

Tool Dimensions Shown: Metric

Inch

Color

EDP

Target Hole Diameter (MM)

D3 Brush Size (mm)

L1 Overall Length (mm)

L4 Brush Length (mm)

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

Max RPM

Product Number

List Price

Red

20007

3.5 to 5

1.5

120

50

3

2.5

20,000

CH-A12-1.5M

$88.92

Red

20001

5 to 8

3

120

50

3

4

14,000

CH-A12-3M

$85.95

Red

20004

5 to 8

3

170

50

4

4

14,000

CH-A12-3L

$153.15

Blue

20008

5 to 8

3

130

60

3

4

14,000

CH-A33-3M

$84.57

Blue

20012

5 to 8

3

180

60

4

4

12,000

CH-A33-3L

$149.24

Red

20002

8 to 10

5

120

50

6

6

14,000

CH-A12-5M

$117.22

Red

20005

8 to 10

5

170

50

6

6

14,000

CH-A12-5L

$196.92

Blue

20009

8 to 10

5

130

60

6

6

14,000

CH-A33-5M

$115.78

Blue

20013

8 to 10

5

180

60

6

6

12,000

CH-A33-5L

$190.59

Red

20003

10 to 14

7

120

50

6

8

14,000

CH-A12-7M

$171.90

Red

20006

10 to 14

7

170

50

8

8

14,000

CH-A12-7L

$257.86

Blue

20010

10 to 14

7

130

60

6

8

14,000

CH-A33-7M

$166.90

Blue

20014

10 to 14

7

180

60

8

8

12,000

CH-A33-7L

$251.49

Blue

20011

14 to 20

11

130

60

12

12

14,000

CH-A33-11M

$192.47

Blue

20015

14 to 20

11

180

60

12

12

12,000

CH-A33-11L

$271.03

Red

20017

14 to 20

11

170

50

12

12

12,000

CH-A12-11L

$243.97

Red

20018

14 to 20

11

120

50

12

12

14,000

CH-A12-11M

$173.66

Dark Blue

20021

20 to 25

15

150

60

6

16

9,000

CH-A34-15

$141.64

Dark Blue

20022

25 to 30

20

150

60

8

21

9,000

CH-A34-20

$163.43

Dark Blue

20023

30 to 35

25

150

60

8

26

9,000

CH-A34-25

$213.53

Color

EDP

Target Hole Diameter (in)

D3 Brush Size (in)

L1 Overall Length (in)

L4 Brush Length (in)

D1 Shank Diameter (in)

D2 Neck Diameter (in)

Max RPM

Product Number

List Price

Red

20007

0.140 to 0.197

0.059

4.724

1.969

0.118

0.098

20,000

CH-A12-1.5M

$88.92

Red

20001

0.197 to 0.315

0.118

4.724

1.969

0.118

0.157

14,000

CH-A12-3M

$85.95

Red

20004

0.197 to 0.315

0.118

6.693

1.969

0.157

0.157

14,000

CH-A12-3L

$153.15

Blue

20008

0.197 to 0.315

0.118

5.118

2.362

0.118

0.157

14,000

CH-A33-3M

$84.57

Blue

20012

0.197 to 0.315

0.118

7.087

2.362

0.157

0.157

12,000

CH-A33-3L

$149.24

Red

20002

0.315 to 0.394

0.197

4.724

1.969

0.236

0.236

14,000

CH-A12-5M

$117.22

Red

20005

0.315 to 0.394

0.197

6.693

1.969

0.236

0.236

14,000

CH-A12-5L

$196.92

Blue

20009

0.315 to 0.394

0.197

5.118

2.362

0.236

0.236

14,000

CH-A33-5M

$115.78

Blue

20013

0.315 to 0.394

0.197

7.087

2.362

0.236

0.236

12,000

CH-A33-5L

$190.59

Red

20003

0.394 to 0.551

0.276

4.724

1.969

0.236

0.315

14,000

CH-A12-7M

$171.90

Red

20006

0.394 to 0.551

0.276

6.693

1.969

0.315

0.315

14,000

CH-A12-7L

$257.86

Blue

20010

0.394 to 0.551

0.276

5.118

2.362

0.236

0.315

14,000

CH-A33-7M

$166.90

Blue

20014

0.394 to 0.551

0.276

7.087

2.362

0.315

0.315

12,000

CH-A33-7L

$251.49

Blue

20011

0.551 to 0.787

0.433

5.118

2.362

0.472

0.472

14,000

CH-A33-11M

$192.47

Blue

20015

0.551 to 0.787

0.433

7.087

2.362

0.472

0.472

12,000

CH-A33-11L

$271.03

Red

20017

0.551 to 0.787

0.433

6.693

1.969

0.472

0.472

12,000

CH-A12-11L

$243.97

Red

20018

0.551 to 0.787

0.433

4.724

1.969

0.472

0.472

14,000

CH-A12-11M

$173.66

Dark Blue

20021

0.787 - 0.984

0.591

5.906

2.362

0.232

0.63

9,000

CH-A34-15

$141.64

Dark Blue

20022

0.984 - 1.181

0.787

5.906

2.362

0.315

0.827

9,000

CH-A34-20

$163.43

Dark Blue

20023

1.181 - 1.378

0.984

5.906

2.362

0.315

1.024

9,000

CH-A34-25

$213.53

Extra-Large, Dark Blue (A34) Brushes require a reusable Shank to operate. Sold separately.

Reusable Shank Required for 15, 20 and 25mm Crosshole Brushes only.

- 15mm, 20021: $141.64

- 20mm, 20022: $163.43

- 25mm, 20023: $213.53

Custom Extra-Long Crosshole Brushes are available for depths exceeding 5.9 inches. This is a Special Order item consisting of brush collar and shank. Contact Customer Service for details.

How to Select

If the target depth is over 140mm, the Extra-Long is available as a custom product.

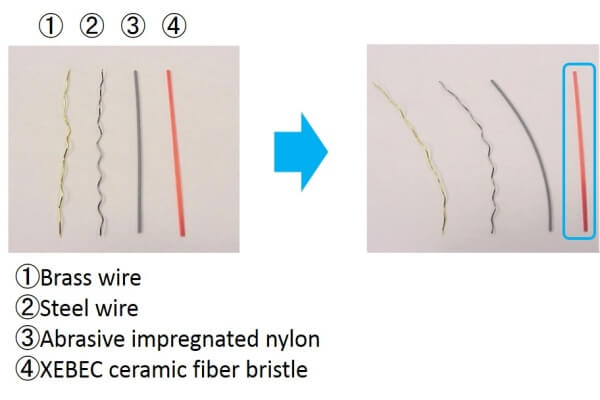

Strucutre of Xebec Ceramic Fiber

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

Strength 1: Unsurpassed Grinding Power

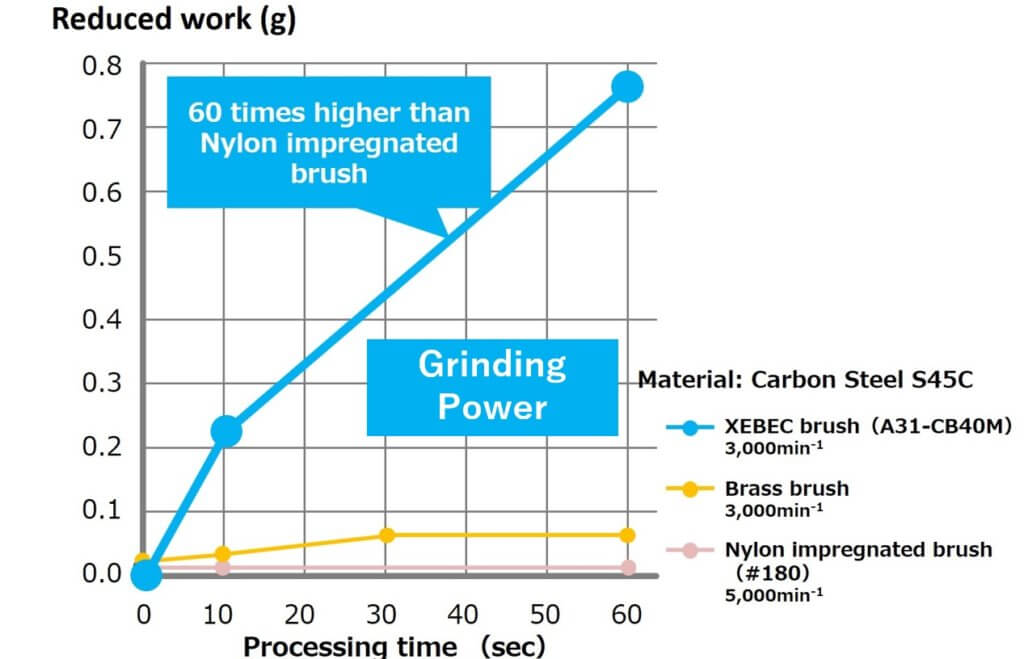

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

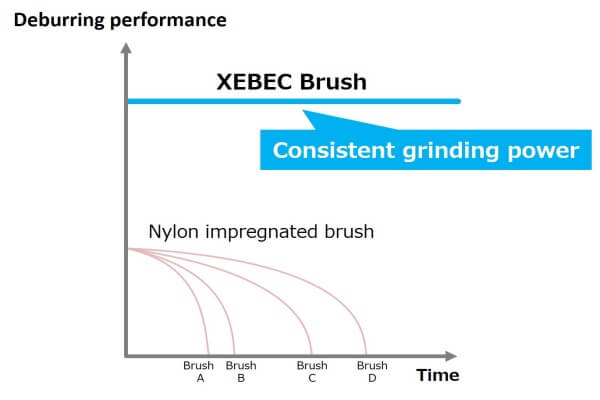

Strength 2: Consistent Grinding Power to the End

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

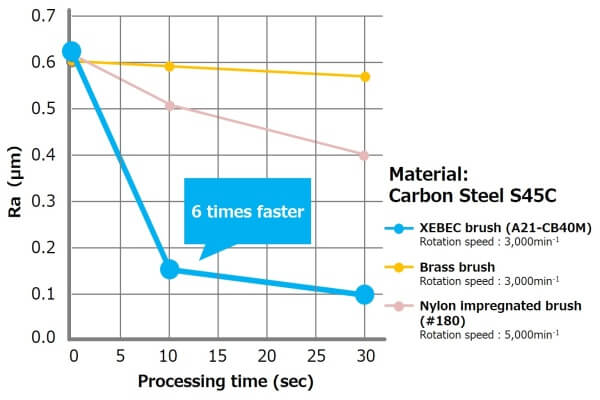

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Target

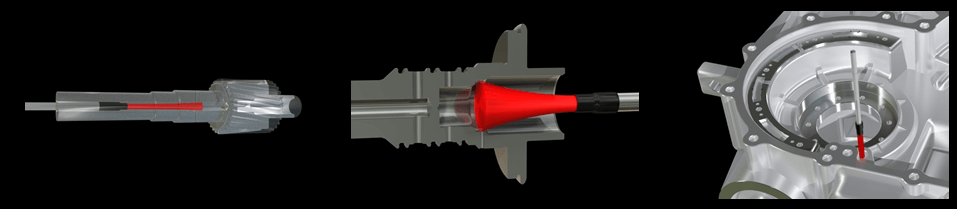

XEBEC Brush™ has high grinding power on the tip, thus the tip of the brush must pass through the part to be processed. When processing a crosshole, it is necessary to rotate the brush at high rotation speed and expand it by centrifugal force.

The target hole diameter is between Φ3.5mm and Φ20mm. If you use the tool beyond the maximum rotation speed or outside the cylinder (outside the workpiece), it may result in brush breakage

Applicable Equipment

The tool can be mounted on an equipment which can control rotation speed. The tool must be rotated over 8,000min-1.

The tool can be used on machining centers, combined lathes, robots, and special machines. It cannot be used with a pneumatic tool.

How To Use

1. Insert the brush while not in motion

*If you rotate the brush outside the cylinder, the bristles may be damaged or scattered and may cause injury to the operator

2. Rotate the tool past the cross-hole

*Consistent edge quality can be obtained by rotating the tool in both CW and CCW direction

3. Process while pulling the brush back

*Pulling the brush back past the crossholes prevents burrs from being laid flat against the interior surface of the cylinder

4. Process while pushing the brush forward

*Pushing the brush forward ensures that burrs remaining upward are removed

5. Stop the brush rotation

6. Remove the brush while it is at rest

Usage Instructions

Precautions for Usage

- Processing beyond the maximum rotation speed may cause brush damage

- Process outside the cylinder (outside workpiece) may cause brush damage

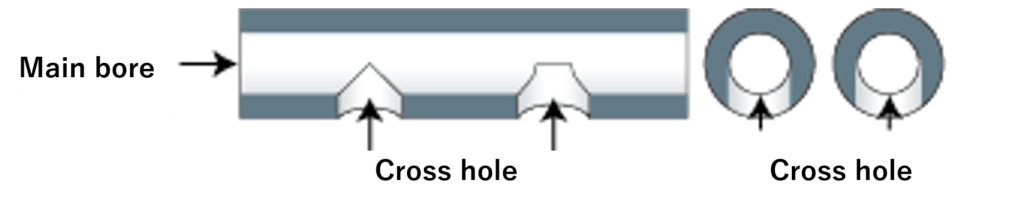

- This tool is not suitable for off-center hole or oblique hole

- In the following cases, it may cause brush damage:

T-Shaped Hole

If the diameter of the cross hole is equal to or greater than the diameter of the main bore. (For example, if the main bore is Φ10 mm and the cross hole is Φ10 mm or larger.)

Cross-Shaped Hole

Process Conditions

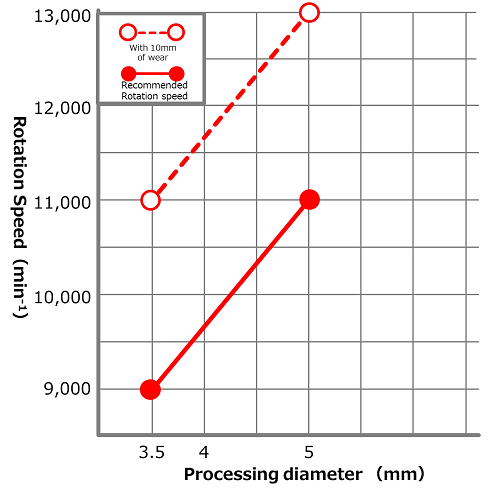

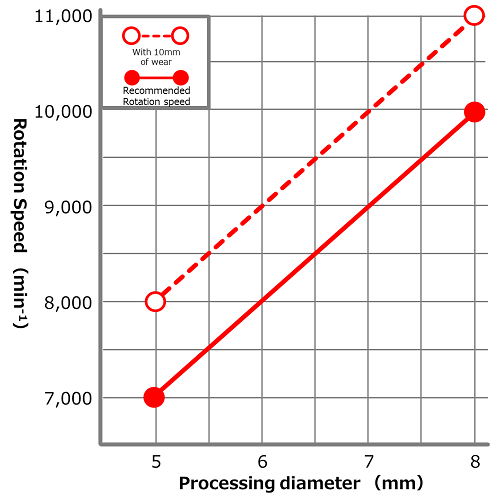

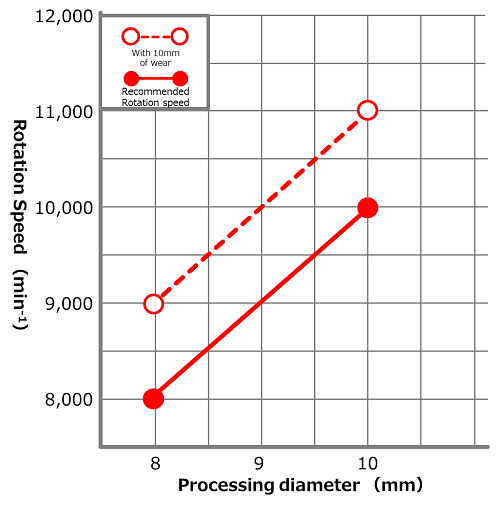

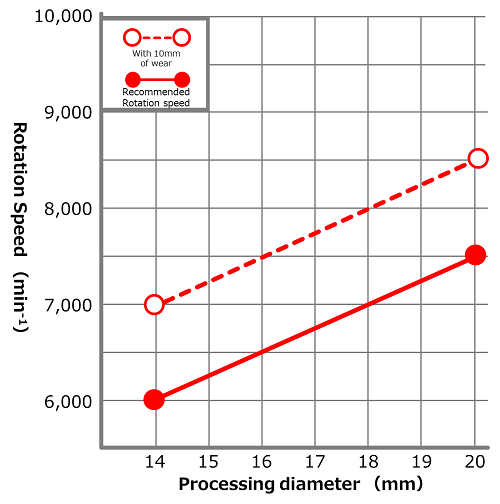

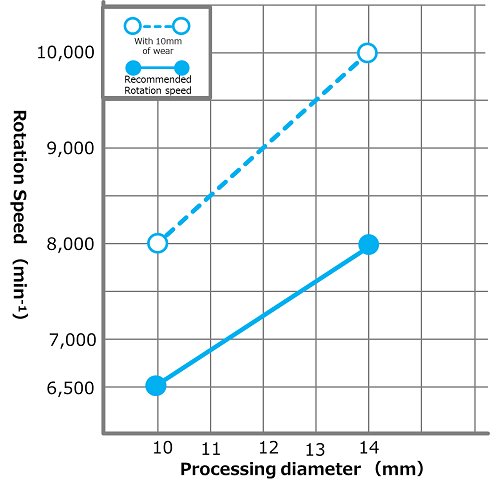

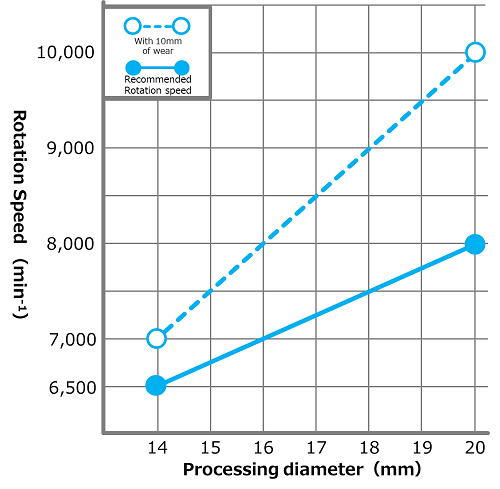

Before using XEBEC Brush™ Crosshole, make sure to set up 2 parameters; rotation speed and feed rate. Recommended rotation speed is different depending on brush diameter. See the recommended rotation speed and the target bore diameter shown below.

A uniform deburring and edge quality can be obtained by rotating the tool in both clockwise and counter-clockwise directions. Start the feed rate from 300mm/min.

Recommended Rotation Speed

The continuous line (-) represents the recommended rotation speed when using a new tool. The dotted line (- – -) represents the diameter of brush expansion when the brush bristles have worn down 10mm. You can continue to use the tool by adjusting (i.e. increasing) the rotation speed according to the wear amount.

CH-A12-1.5M (Φ1.5mm Red Brush)

Target Hole Diameter: Φ3.5 ~ Φ5mm

Recommended Rotation Speed: 9,000 ~ 11,000min-1

CH-A12-3M / CH-A12-3L (Φ3mm Red Brush)

Target Hole Diameter: Φ5 ~ Φ8mm

Recommended Rotation Speed: 7,000 ~ 10,000min-1

CH-A12-5M / CH-A12-5L (Φ5mm Red Brush)

Target Hole Diameter: Φ8 ~ Φ10mm

Recommended Rotation Speed: 8,000 ~ 10,000min-1

CH-A12-7M / CH-A12-7L (Φ7mm Red Brush)

Target Hole Diameter: Φ10 ~ Φ20mm

Recommended Rotation Speed: 7,000 ~ 9,000min-1

CH-A12-11M / CH-A12-11L (Φ11mm Red Brush)

Target Hole Diameter: Φ14 ~ Φ20mm

Recommended Rotation Speed: 6,000 ~ 7,500min-1

CH-A33-3M / CH-A33-3L (Φ3mm Blue Brush)

Target Hole Diameter: Φ5 ~ Φ8mm

Recommended Rotation Speed: 7,500 ~ 9,000min-1

CH-A33-5M / CH-A33-5L (Φ5mm Blue Brush)

Target Hole Diameter: Φ8 ~ Φ10mm

Recommended Rotation Speed: 7,500 ~ 8,000min-1

CH-A33-7M / CH-A33-7L (Φ7mm Blue Brush)

Target Hole Diameter: Φ10 ~ Φ14mm

Recommended Rotation Speed: 6,500 ~ 8,000min-1

CH-A33-11M / CH-A33-11L (Φ11mm Blue Brush)

Target Hole Diameter: Φ14 ~ Φ20mm

Recommended Rotation Speed: 6,500 ~ 8,000min-1

If burrs remain:

- Increase the rotation speed to the upper limit of 1,000min-1 or increase the number of passes. (Be careful not to exceed the maximum rotation speed.)

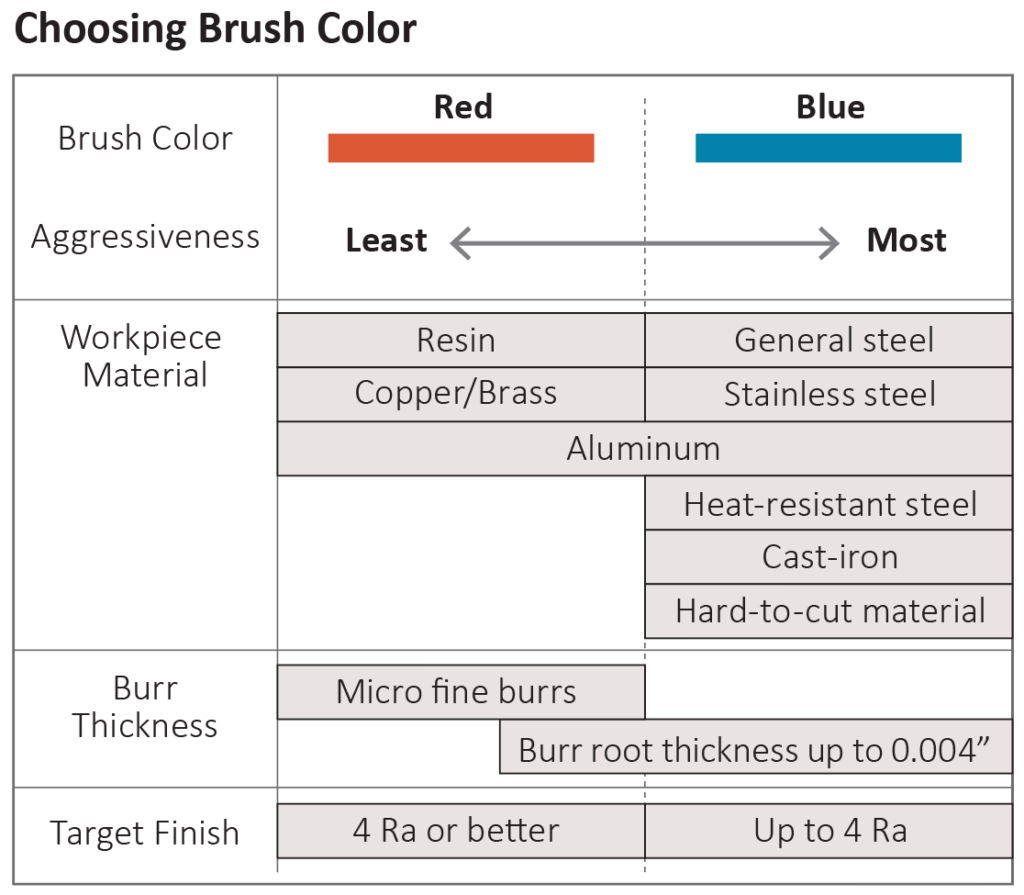

- If the workpiece cannot be deburred even by the above-metioned procedures, the machining condition may be incorrect or the burr size is too large. Change the brush to a higher grinding power. The blue brush has higher grinding power than the red brush.

To extend tool life/If the edge is too rounded:

- Decrease the rotation speed in increments of 500min-1 or increase the feed rate in increments of 100mm/min.

Truing

If the brush deforms through usage, you can form the tips of the brush using a diamond disc blade. Drilling machine or lathe can be used for forming.

Perform truing while suppressing dispersion of the bristles by wrapping the brush with tape.

Truing by Lathe

If you want to cut off the brush, cut from the side of the brush using a diamond disc blade and sever it.

Operator Safety Measures

For Protective Equipment

Always wear protective goggles, gloves and masks when operating the tool. Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Beware of Grinding Powder

Grinding powder and burrs may scatter within an area around the work as the brush revolves; please stay clear of this area.

Be Aware of Your Surroundings

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter, enclose your working area to prevent other people entering, or have the people surrounding your work area protective equipment as well.

Warning

By not following the above safety measures, you are vulnerable to the following risks:

- A tool or a part of a tool may crack, drop off, distort or break.

- Broken pieces of a tool or grinding dust may stick into your skin and eyes, causing irritation and/or blindness.

- Dust generated by machining process may cause allergic reactions.

Recommended rotation speed is 8,000min-1 – 10,000min-1. Because XEBEC Brush™ Crosshole has high grinding power on the tip, the brush tip needs to be in contact with the machining area (the part where burrs occur). When machining the hole, it is necessary to rotate the brush to expand it by centrifugal force.

NC equipment and special machines can be used, but a rotation speed of 8,000min-1-1200min-1 is required. If the rotation speed does not go up, use an amplifier to increase the rotation speed.

The tool aims to remove fine burrs with the burr root thickness of 0.1mm or less (approximately the size that can be bent by pushing one’s fingernail against burrs).

Workpiece materials up to HRC65 including stainless steel, aluminum alloy, general steel material, copper and resin.

The target hole diameter of the main bore is between 3.5 mm and 35 mm.

The target diameter is set to slightly smaller than the safety value because the tip spreads out a little.

Usually, we recommend inserting without rotation when inserting the brush into the workpiece, but rotating the brush in low speed at around 300min-1 would keep the brush tip together, and it may be possible to insert the brush into a hole that is smaller than the target hole. In addition, if there is a chamfer on the hole edge, it would be easier to insert the brush, so it may be possible to insert the brush into a hole with a diameter that is smaller than the target hole diameter.

It is capable of finishing the surface up to around Ra-0.1μm.

There is a possibility that it will be ground by a few μm, although this depends on material and machining conditions.

The tool can be used for both dry and wet (both oil-based and water-soluble) machining, so you can use the coolant. Wet machining may improve surface finish quality and tool life.

Unlike nylon bristles and wire bristles, XEBEC Brush™ does not deform after machining (the tip does not spread like toothbrushes), so stable machining is possible.

Offset the brush when it becomes shorter, the tool is often used by moving the brush about 1mm up and down against the target crosshole.

Aim to replace the tool when it is worn out 10mm. When the brush is worn out 10mm, it is necessary to increase the rotation speed to expand the brush enough to deburr.

Manage the number of machined workpieces. In general cases, users perform a test and record the number of workpieces at which burrs can no longer be removed, and they set the tool life at about 80% to 90% of that number.

In the following cases, brush damage may occur.

T-Shaped Hole

If the diameter of the cross hole is equal to or greater the diameter of the main bore. (For example, if the main bore is Φ10 mm and the cross hole is Φ10 mm or larger.)

Cross-Shaped Hole

If the diameter of the cross hole is more than 70% of the diameter of the main bore. (For example, if the main bore is Φ10 mm and the cross hole is Φ7 mm or larger.)

Perform an initial test while monitoring the behavior of the brush tip, and confirm that the brush does not break before use.

Remove the attached dust or coolant by blowing air, etc.

You can regrind the brush by forming it using a diamond electrodeposited grinding stone. We do not offer regrinding or re-embedding services.

No, it is not possible. The number of bristles of CH-A12-1.5M (brush diameter Φ1.5mm) is about 7, and tools with less bristles than this are not expected to be effective due to reduced grinding power.

Yes, we provide services such as extension of bristle length for standard brushes and modification of the brush tip shape. Please contact us for more information.

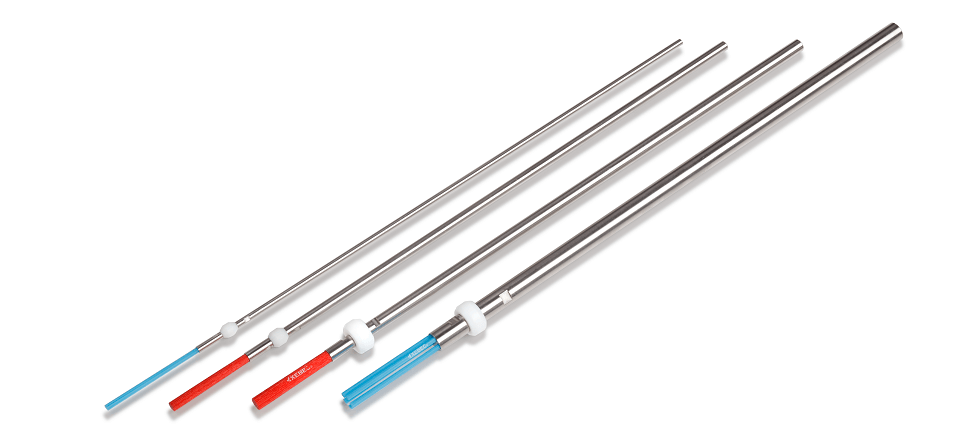

XEBEC Brush™ Crosshole Extra-Long

XEBEC Brush™ Crosshole Extra-Long is suitable for a bore depth over 140mm up to 370mm when chucking allowance is 30mm. Full length of the tool is 400mm for a red brush (A12) and 410mm for a blue brush (A33).

The basic usage method is same as XEBEC Brush™ Crosshole, however the difference from XEBEC Brush™ Crosshole is that a resin collar must be attached to prevent deflection. Also, always make sure to use the tool in a state where the resin collar is stored inside the workpiece

XEBEC Brush™ Crosshole Extra-Long is a customized item. The shank and the brush part are separate items and the shank part can be reusable.

Selection

Product Code

Brush Color

Brush Diameter A

Collar Diameter B

Shank Diameter C

Full Length

CH-A12-3F

CH-A12-5F

CH-A12-7F

CH-A12-11F

Φ3mm

Φ5mm

Φ7mm

Φ11mm

Φ4.8 ~ 7.8mm

Φ7.8 ~ 9.8mm

Φ9.8 ~ 19.8mm

Φ13.8 ~ 19.8mm

Φ4mm

Φ6mm

Φ8mm

Φ8mm

400mm

400mm

400mm

400mm

CH-A33-3F

CH-A33-5F

CH-A33-7F

CH-A33-11F

Φ3mm

Φ5mm

Φ7mm

Φ11mm

Φ4.8 ~ 7.8mm

Φ7.8 ~ 9.8mm

Φ9.8 ~ 19.8mm

Φ13.8 ~ 19.8mm

Φ4mm

Φ6mm

Φ8mm

Φ8mm

410mm

410mm

410mm

410mm

Tool Schematic

Brush part is replaceable and shank part can be reused.

Processing Conditions

Product Code

Target Bore Φ

Recommended RPM

Maximum RPM

CH-A12-3F

Φ5 ~ 8mm

7,000 ~ 10,000min-1

12,000min-1

CH-A12-5F

Φ8 ~ 10mm

8,000 ~ 10,000min-1

12,000min-1

CH-A12-7F

Φ10 ~ 14mm

7,000 ~ 9,000min-1

12,000min-1

CH-A12-11F

Φ14 ~ 20mm

6,000 ~ 7,500min-1

12,000min-1

CH-A12-11F

Φ5 ~ 8mm

7,500 ~ 9,000min-1

12,000min-1

CH-A33-5F

Φ8 ~ 10mm

7,500 ~ 8,000min-1

12,000min-1

CH-A33-7F

Φ10 ~ 14mm

6,500 ~ 8,000min-1

12,000min-1

CH-A33-11F

Φ14 ~ 20mm

6,500 ~ 8,000min-1

12,000min-1

Assembly

- Attach the collar to the shank and thrust in the brush holder to the shank. Make sure to insert the brush holder all the way to the end (there should be no gap between the contacting surfaces). Use two wrenches to securely tighten and fix it with the permissible tightening force shown in the table above.

- After fixing it, check that there is no gap between the contacting surfaces of the brush holder and shank. Make sure that the collar rotates with ease. Otherwise, disassemble and clean the tool because foreign materials may have entered.

Collar

- Select a collar with diameter that is around 0.2mm to 0.3mm smaller than the inner diameter of the target hole.

- The collar is an expendable product that wears down. When the tool's rotational vibration becomes large, replace it with a new one (periodic replacement or replacement at the same time as brush is recommended).

- Collar may wear out faster where the inner peripheral surface of the primary processing hole is rough. Replace the collar to a new one when the amount of wear reaches dia. 0.5mm.

- Once the deflection of the tip of the tool exceeds 0.5mm, stop using it and replace it with a new shank (periodic replacement is recommended). (It is very dangerous to use the tool when the deflection exceeds 0.5mm because there is a risk that the shank will break and scatter.)

Precautions

- Select a collar with diameter that is around 0.2mm to 0.3mm smaller than the inner diameter of the target hole.

- The collar is an expendable product that wears down. When the tool's rotational vibration becomes large, replace it with a new one (periodic replacement or replacement at the same time as brush is recommended).

- Collar may wear out faster where the inner peripheral surface of the primary processing hole is rough. Replace the collar to a new one when the amount of wear reaches dia. 0.5mm.

- Once the deflection of the tip of the tool exceeds 0.5mm, stop using it and replace it with a new shank (periodic replacement is recommended). (It is very dangerous to use the tool when the deflection exceeds 0.5mm because there is a risk that the shank will break and scatter.)