Products

XEBEC Stone™ Flexible Shaft

XEBEC Stone™ Flexible Shaft

Soft contact abrasive ceramic fiber stone with cutting edges exposed across the entire surface. For deburring cross holes and detailed finishing of parts in CNC machines, robots or hand-held rotary tools. Available with ball, cylinder or disc type stones.

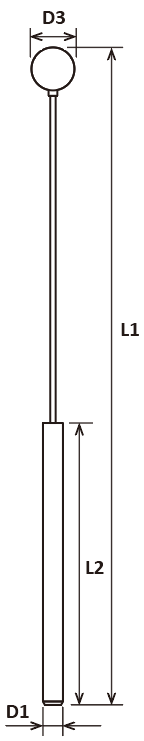

Ball Type

Show Tool Diameter and Length in: MM

in

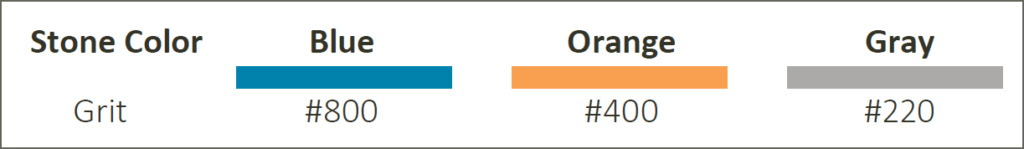

Color

EDP

Ball Size (D3)

L1 Overall Length (mm)

D1 Shank Diameter (mm)

L2 Shank Length (mm)

Max RPM

Product Number

List Price

Blue

10001

3

71.5

3

30

15,000

CH-PB-3B

$40.62

Blue

10002

4

72

3

30

13,000

CH-PB-4B

$48.45

Blue

10003

5

72.5

3

30

12,000

CH-PB-5B

$53.14

Blue

10004

6

73

3

30

10,000

CH-PB-6B

$57.84

Orange

10008

3

71.5

3

30

15,000

CH-PO-3B

$40.62

Orange

10009

4

72

3

30

13,000

CH-PO-4B

$48.45

Orange

10010

5

72.5

3

30

12,000

CH-PO-5B

$53.14

Orange

10011

6

73

3

30

10,000

CH-PO-6B

$57.84

Gray

10015

3

71.5

3

30

15,000

CH-PM-3B

$40.62

Gray

10016

4

72

3

30

13,000

CH-PM-4B

$48.45

Gray

10017

5

72.5

3

30

12,000

CH-PM-5B

$53.14

Gray

10018

6

73

3

30

10,000

CH-PM-6B

$57.84

Gray

10027

10

75

3

30

7,000

CH-PM-10B

$79.87

Color

EDP

Ball Size (D3)

L1 Overall Length (in)

D1 Shank Diameter (in)

L2 Shank Length (in)

Max RPM

Product Number

List Price

Blue

10001

0.118

2.815

0.118

1.181

15,000

CH-PB-3B

$40.62

Blue

10002

0.157

2.835

0.118

1.181

13,000

CH-PB-4B

$48.45

Blue

10003

0.197

2.854

0.118

1.181

12,000

CH-PB-5B

$53.14

Blue

10004

0.236

2.874

0.118

1.181

10,000

CH-PB-6B

$57.84

Orange

10008

0.118

2.815

0.118

1.181

15,000

CH-PO-3B

$40.62

Orange

10009

0.157

2.835

0.118

1.181

13,000

CH-PO-4B

$48.45

Orange

10010

0.197

2.854

0.118

1.181

12,000

CH-PO-5B

$53.14

Orange

10011

0.236

2.874

0.118

1.181

10,000

CH-PO-6B

$57.84

Gray

10015

0.118

2.815

0.118

1.181

15,000

CH-PM-3B

$40.62

Gray

10016

0.157

2.835

0.118

1.181

13,000

CH-PM-4B

$48.45

Gray

10017

0.197

2.854

0.118

1.181

12,000

CH-PM-5B

$53.14

Gray

10018

0.236

2.874

0.118

1.181

10,000

CH-PM-6B

$57.84

Gray

10027

0.394

2.953

0.118

1.181

7,000

CH-PM-10B

$79.87

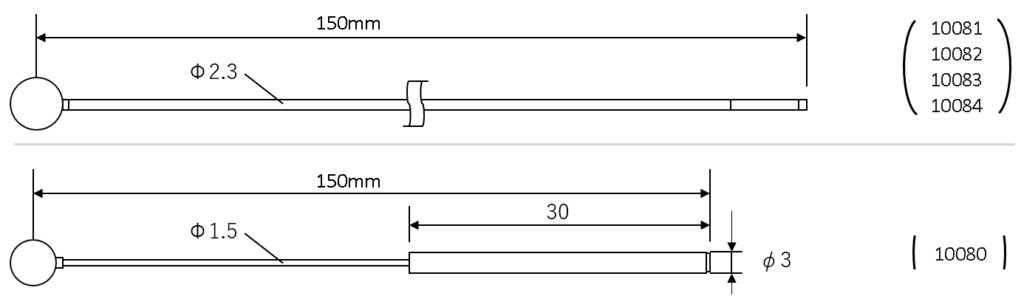

Extended Length Ball

Show Tool Diameter and Length in: MM

in

Color

EDP

Ball Size (D3)

L1 Overall Length (mm)

D1 Shank Diameter (mm)

L2 Shank Length (mm)

Max RPM

Product Number

List Price

Gray

10080

3

151.5

3

30

1,000

CH-PM-3B-L

$57.13

Gray

10081

4

152

2.3

N/A

3,000

CH-PM-4B-L

$57.13

Gray

10082

5

152.5

2.3

N/A

3,000

CH-PM-5B-L

$59.99

Gray

10083

6

153

2.3

N/A

3,000

CH-PM-6B-L

$64.28

Gray

10084

10

155

2.3

N/A

2,000

CH-PM-10B-L

$77.12

Color

EDP

Ball Size (D3)

L1 Overall Length (in)

D1 Shank Diameter (in)

L2 Shank Length (in)

Max RPM

Product Number

List Price

Gray

10080

0.118

5.965

0.118

1.181

1,000

CH-PM-3B-L

$57.13

Gray

10081

0.157

5.984

0.091

N/A

3,000

CH-PM-4B-L

$57.13

Gray

10082

0.197

6.004

0.091

N/A

3,000

CH-PM-5B-L

$59.99

Gray

10083

0.236

6.024

0.091

N/A

3,000

CH-PM-6B-L

$64.28

Gray

10084

0.394

6.102

0.091

N/A

2,000

CH-PM-10B-L

$77.12

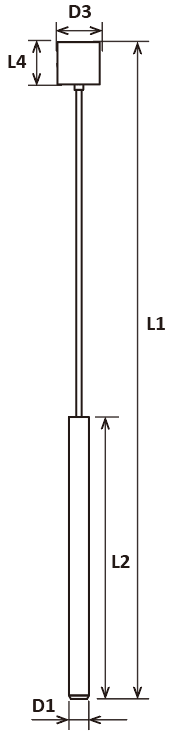

Cylinder Type

Show Tool Diameter and Length in: MM

in

Color

EDP

Cylinder Size

(D3 x L4)

L1 Overall Length (mm)

D1 Shank Diameter (mm)

L2 Shank Length (mm)

Max RPM

Product Number

List Price

Blue

10005

3

x

3

71.5

3

30

15,000

CH-PB-3R

$40.62

Blue

10006

4

x

4

72

3

30

13,000

CH-PB-4R

$48.45

Blue

10007

5

x

5

72.5

3

30

12,000

CH-PB-5R

$53.14

Orange

10012

3

x

3

71.5

3

30

15,000

CH-PO-3R

$40.62

Orange

10013

4

x

4

72

3

30

13,000

CH-PO-4R

$48.45

Orange

10014

5

x

5

72.5

3

30

12,000

CH-PO-5R

$134.75

Gray

10019

3

x

3

71.5

3

30

15,000

CH-PM-3R

$40.62

Gray

10020

4

x

4

72

3

30

13,000

CH-PM-4R

$48.45

Gray

10021

5

x

5

72.5

3

30

12,000

CH-PM-5R

$53.14

Gray

10022

5

x

10

75

3

30

12,000

CH-PM-5R

$67.11

Color

EDP

Cylinder Size

(D3 x L4)

L1 Overall Length (in)

D1 Shank Diameter (in)

L2 Shank Length (in)

Max RPM

Product Number

List Price

Blue

10005

0.118

x

0.118

2.815

0.118

1.181

15,000

CH-PB-3R

$40.62

Blue

10006

0.157

x

0.157

2.835

0.118

1.181

13,000

CH-PB-4R

$48.45

Blue

10007

0.197

x

0.197

2.854

0.118

1.181

12,000

CH-PB-5R

$53.14

Orange

10012

0.118

x

0.118

2.815

0.118

1.181

15,000

CH-PO-3R

$40.62

Orange

10013

0.157

x

0.157

2.835

0.118

1.181

13,000

CH-PO-4R

$48.45

Orange

10014

0.197

x

0.197

2.854

0.118

1.181

12,000

CH-PO-5R

$134.75

Gray

10019

0.118

x

0.118

2.815

0.118

1.181

15,000

CH-PM-3R

$40.62

Gray

10020

0.157

x

0.157

2.835

0.118

1.181

13,000

CH-PM-4R

$48.45

Gray

10021

0.197

x

0.197

2.854

0.118

1.181

12,000

CH-PM-5R

$53.14

Gray

10022

0.197

x

0.394

2.953

0.118

1.181

12,000

CH-PM-5R

$67.11

Disc Type

Show Tool Diameter and Length in: MM

in

Color

EDP

Cylinder Size

(D3 x L4)

L1 Overall Length (mm)

D1 Shank Diameter (mm)

Required Shaft

Max RPM

Product Number

List Price

Gray

10030

14

x

2

78

2.3

5,000

CH-PM-14D

$43.86

Color

EDP

Cylinder Size

(D3 x L4)

L1 Overall Length (in)

D1 Shank Diameter (in)

Required Shaft

Max RPM

Product Number

List Price

Gray

10030

0.551

x

0.079

3.071

0.091

5,000

CH-PM-14D

$43.86

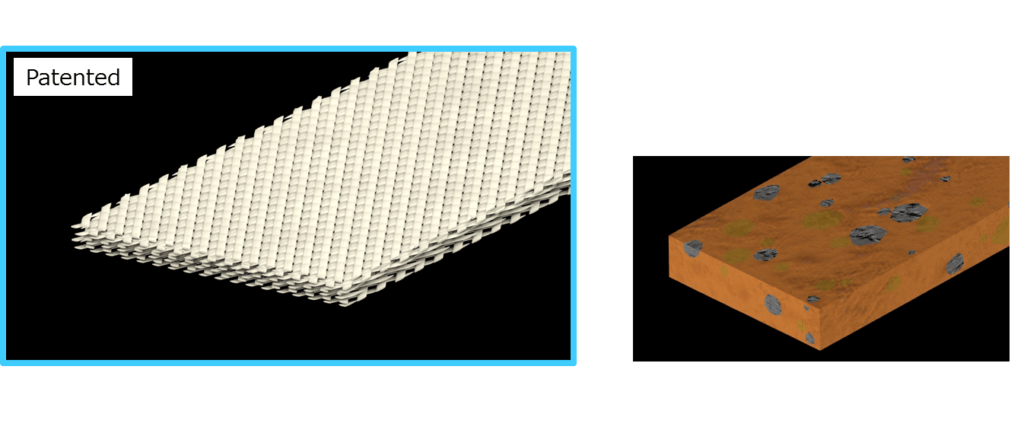

Strucutre of Xebec Stone™

XEBEC Stone™ uses the original abrasive ceramic fiber material instead of abrasive grains. By using ceramic stone on the head portion, the cutting edges are exposed over the entire surface. This tool prevents clogs and scratches to the surface because it does not contain abrasive grains.

Target

XEBEC Stone™ Flexible Shaft has grinding power on the entire surface of the head portion. It allows deburring in various ways as long as the tip of the head portion contacts with the processing area.

The ball type is capable of deburring hole edge after drilling by point processing or removing back burrs after drilling by contouring.

The cylinder type is suitable for deburring blind holes.

Applicable Equipment

The tool can be mounted on equipment that control the rotation speed. It can be used on machining center, combined lathe, robot, special machine, and drilling machine, as well as an electronic grinding tool.

How to Use

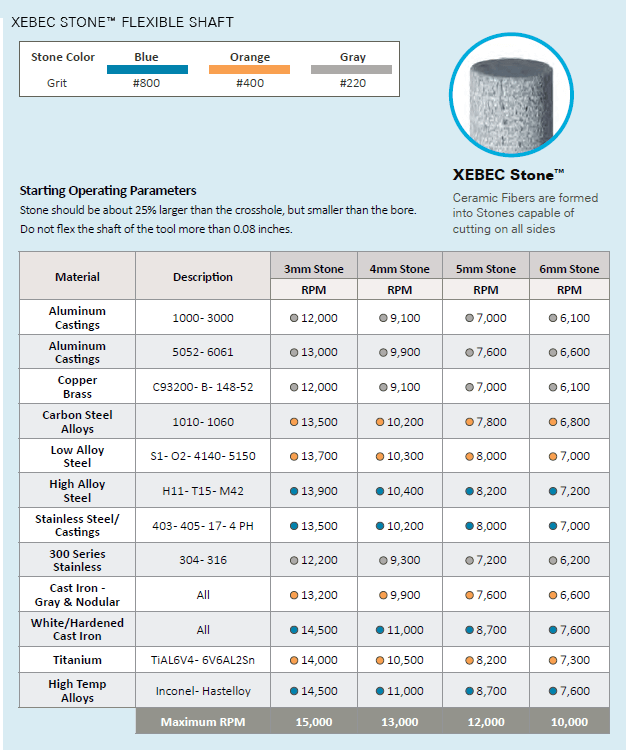

Rotation Speed

The tool has high grinding power even at low rotation speed. Start from 1,000min-1, and then gradually increase the rotation speed.

Head Diameter

Maximum Rotation Speed

Φ3mm

15,000min-1

Φ4mm

13,000min-1

Φ5mm

12,000min-1

Φ6mm

10,000min-1

Φ10mm

6,000min-1

Usage over the maximum rotation speed may result in breakage of the head and shaft.

Depth of Cut

Gently place the head on the workpiece. Aim for approximately 1N (100g, bending displacement of 0.5mm).

Feed

Start from 300mm/min. There is no upper limit of use.

Deburring After Drilling

Use the ball head size slightly larger than the edge size and deburr by pressing the head against it.

Deburring Around a Blind Hole After Drilling

Use the cylinder-shaped head type and deburr by pressing it against the hole while moving it up and down.

Deburring Back Burr After Drilling

Use the ball head type that is slightly smaller than the edge size, and deburr by contouring.

Deburring the Top Burr After Grooving

Use the ball head type that is slightly larger than the groove width, and deburr by moving the head back and forth across the groove.

Truing

If the tool head (ceramic stone) is deformed from use, reshape it by lightly pressing the periphery onto a diamond disc blade while rotating the tool.

You can also customize the shape based on your preference according to the application or workpiece shape.

Operator Safety Measures

For Protective Equipment

Always wear protective goggles, gloves and masks when operating the tool. Wear long sleeves, tight cuff, and clothing to minimize skin exposure.

Beware of Grinding Powder

Grinding powder and burrs may scatter within an area around the work as the brush revolves; please stay clear of this area.

Be Aware of Your Surroundings

The area around your work is hazardous in case flying pieces of fiber rods from the tools and grinding powder may scatter, enclose your working area to prevent other people entering, or have the people surrounding your work area protective equipment as well.

Warning

By not following the above safety measures, you are vulnerable to the following risks:

- A tool or a part of a tool may crack, drop off, distort or break.

- Broken pieces of a tool or grinding dust may stick into your skin and eyes, causing irritation and/or blindness.

- Dust generated by machining process may cause allergic reactions.

It is made of ceramic stone for mold polishing. The entire surface of the ceramic stone has grinding power.

Workpiece materials including metals of HRC57 or less such as stainless steel, aluminum alloy, general steel material and copper, as well as resin.

Yes, it is possible to remove back burrs by contouring.

The shaft will break if you use it at high rotation speed on a pneumatic tool, so be absolutely sure to use it on an electric tool that can control the rotation speed.

According to XEBEC test data, the tool life is over 30 times longer than rubber stone with flexible shaft and over 10 times longer than grinding stone with vitrified shaft.

No, this is not possible, because the shaft diameter is 1.5mm and the embedded part of the shaft would occupy most of the surface area of the ceramic stone.

Yes, we provide services such as modification of the shape of the grinding stone on the tip of standard products. Contact us for more information.