The Xebec Difference

Xebec Product Characteristics and Features

More than a brush - performs like a cutting tool.

Xebec’s cutting fiber is the world’s only brush made by continuous ceramic fiber. This unique material allows for high performance grinding power, consistent performance and superior surface finish. The fibers are formed into bristles for brushes or bound into stones. Self-sharpening tips lead to superior grinding performance. End-to-end solid abrasive rod material assures consistent performance.

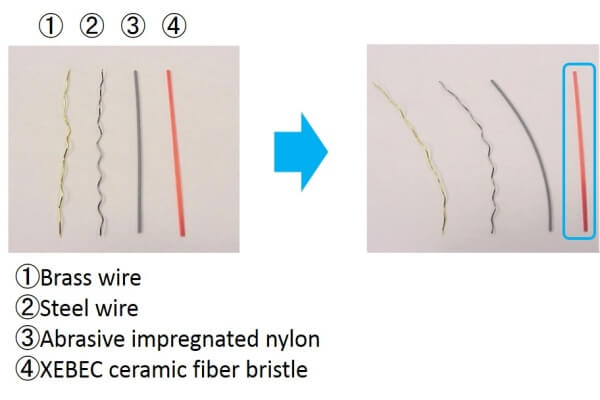

Unlike brass wire, steel wire and abrasive impregnated nylon brush filaments, the unique design of the XEBEC fiber rod allows it to maintain its shape with no deformation even after repeated use. This leads to consistent performance time after time. Achieve a beautiful, finely finished surface without tool marks or residues.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

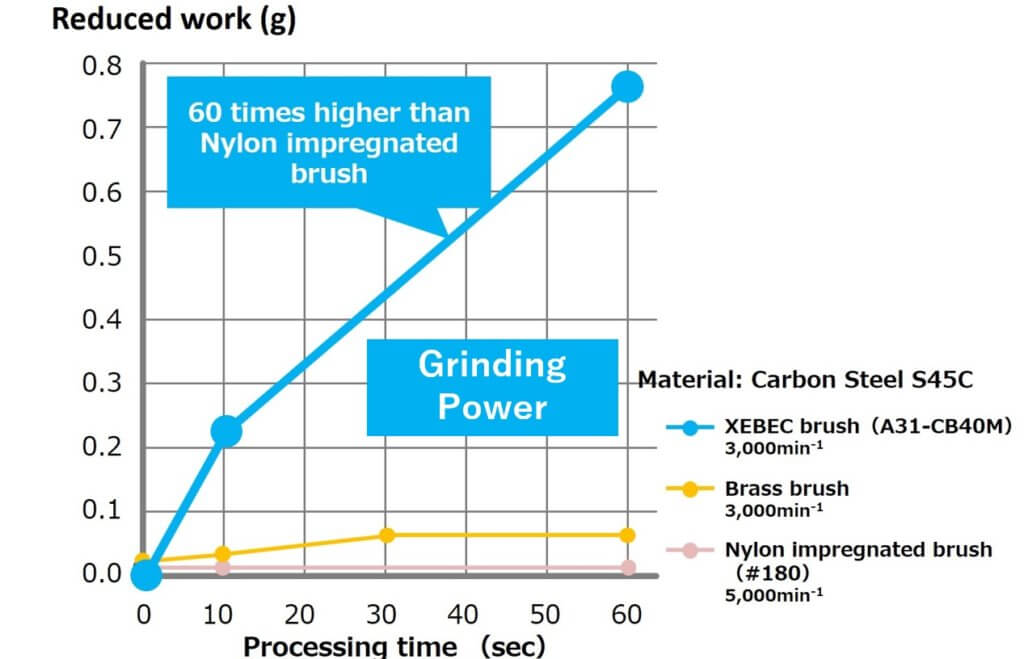

Strength 1: Unsurpassed Grinding Power

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

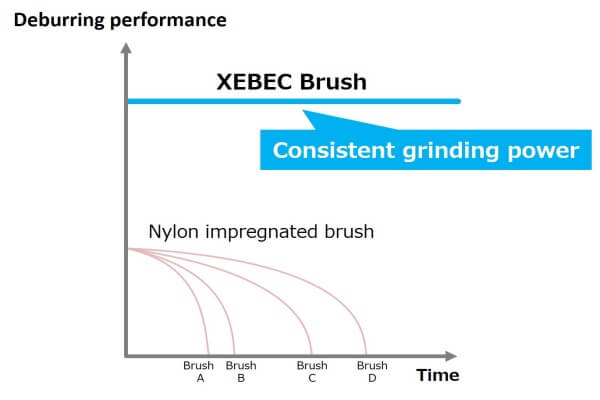

Strength 2: Consistent Grinding Power to the End

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

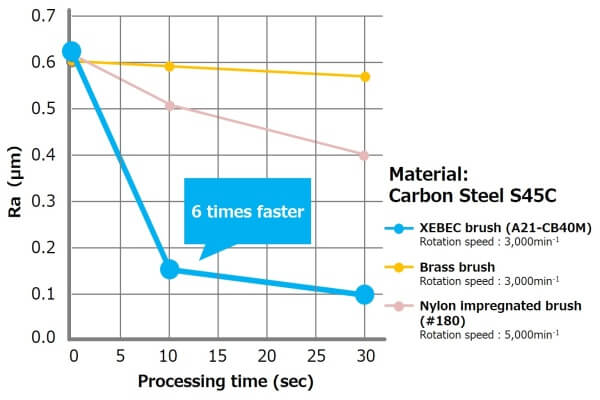

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Features of Xebec Back Burr Cutter

A helical cutting tool and customized tool path data for guaranteed burr-free performance.

The Back Burr Cutter

- Micro-grain cemented carbide: Sharp and long lasting

- Highly heat-resistant AlTiCrN coating: Support materials from non-ferrous (e.g. aluminum) to difficult-to-cut materials (e.g. titanium and inconel)

- Helical Blade: Cleaner cutting edge and prevent secondary burrs

- Uniform Edge Shape by Consistent Deburring Amount

- Faster Operating Time Thanks to the Unique Cutter Design

- Long Tool Life by Using the Entirety of the Cutting Blade

- The contact points of the spherical cutting edge is continuously shifting. The red part shows the range of the blade use.

Applicable Areas

Applicable Areas For a variety of edge shapes

One cutter size supports various edge profiles in different sizes and shapes.

Xebec™ Path Xebec™ Back Burr Cutter

- Optimal path is programmed by Xebec

- Consistent deburring amounts result in a uniform edge shape

- Faster operating time thanks to the unique cutter design

- Entirety of the cutting blade is used providing a longer tool life

More than a brush - performs like a cutting tool.

A turn-key deburring solution. Customized tool path data for complex edge profiles using Xebec® Back Burr Cutter & Custom Path with guaranteed burr-free performance.