Learning Center Blog

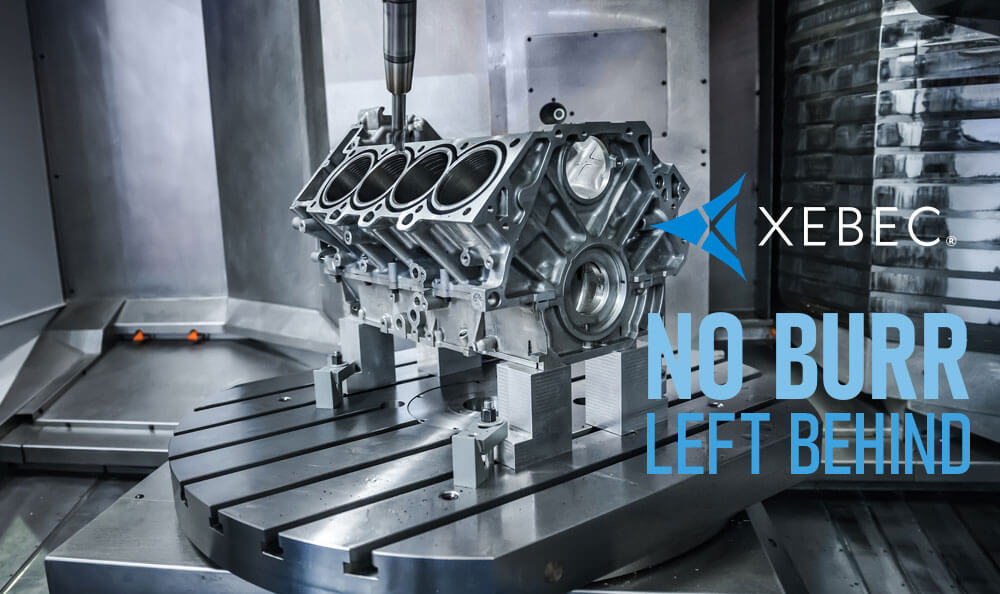

The powertrain industry can reduce burr formation with Xebec for better production output, quality consistency and safety….

Xebec modern deburring and finishing tools help manufacturers and CNC machine shops improve efficiency and quality….

Some issues that come up at a manufacturing organization have cut-and-dry solutions, while others don’t. For instance, equipment break downs are a nuisance and can cause costly downtime, but it’s a knowable issue with a defined solution: repair or…

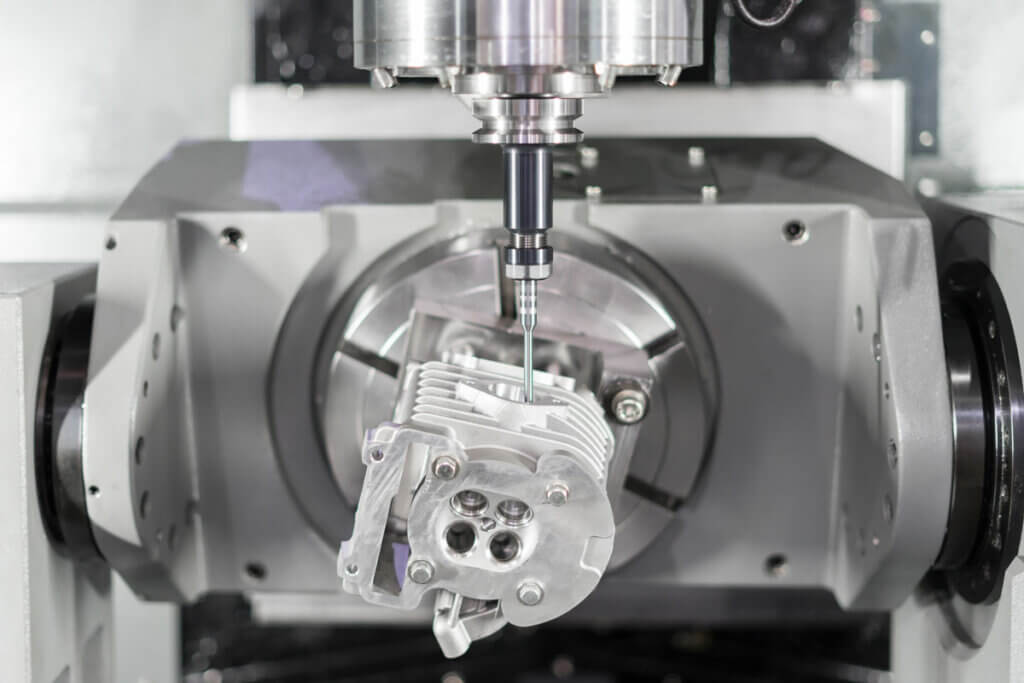

Xebec Deburring Technologies offers the best cutting tool for finishing and deburring for to meet the critical specifications of aerospace and defense industries. …

Improve machine shop productivity by thread deburring with Xebec ceramic fiber brushes. Contact IPT America to learn about our thread deburring tools….

Xebec Deburring Technologies offers the best cutting tool for a chamfer edge, guaranteed to eliminate secondary burrs….

Xebec Deburring Technologies can help you resolve deburring and finishing issues: inconsistencies, rework and scrap. Call us today to see how we can help at 800-306-5901….

Manufacturers and machine shops have a plethora of options for deburring and finishing metal parts. However, choosing the right option for your operations is key to meeting expectations for spec, quality, timing, tool wear, and more….

Automated XEBEC ceramic fiber brushes make deburring and polishing a one-step process….

How to Optimize Performance and Maximize Tool Life of your Xebec Deburring & Finishing Brushes…