Manufacturers and machine shops have a plethora of options for deburring and finishing metal parts and other materials, such as PEEK plastic. However, choosing the right option for your operations is key to meeting expectations for spec, quality, timing, tool wear, and more.

For high-precision parts, manual deburring using any basic brush won’t do. There are too many risks related to part quality, operational efficiency, safety and resource waste. Instead, you’ll find greater success and cost-efficiency with high-performance, automated brushes that perform more like cutting tools, like Xebec ceramic fiber brushes.

For example, the following industries typically require high-precision part production:

- Medical industry manufacturing

- Fluid power and motion control industry manufacturing

- Aerospace industry manufacturing

- Mold and die industry manufacturing

- Powertrain component manufacturing

- Energy industry component manufacturing

- Firearm component manufacturing

So, where manual deburring may make sense for small, one-off jobs, it’s usually not efficient or cost-effective enough for anything more. Many shops are considering automating their deburring and finishing processes or have already done so. For some, this can be a major leap, as the range of options for deburring methods goes from handmade tools in a manual process to sophisticated, automated tools in a CNC machine or robot.

Ultimately, when you compare Xebec ceramic fiber to other material and process options for deburring, it’s like comparing apples to oranges. Ceramic fiber brushes perform more like cutting tools than brushes. They’re durable, get each job done better, faster and more efficiently, and have a significantly longer tool life. Even machine shops with a small volume of deburring projects see benefits in cost and productivity with these tools.

If you’re curious how such a tool could fit into your process – and save you the most time and money – our application experts are the secret to success. Be sure to reach out.

“It looks like a brush and feels like a brush, but it is a cutting tool. That’s imperative to understand at the machining level. It’s controllable like a cutting tool. Another important thing is that it’s deburring and surface finishing at the same time. Ultimately, they’re getting both.”

– Brett Reeder, Director at Xebec/ Deburring Technologies

Commonly Used Deburring Brushes and Tools

There are a variety of deburring brushes for different applications and at different price points. With each, you’ll also get varied performance and quality. If you’re moving to an automated deburring process and shopping brushes, or if you’re unsatisfied with the brushes you use, it might help to see common options directly compared.

DIY Handheld Deburring Tools

These are employee-concocted tools constructed with items like dowel rods, cotton swabs and an abrasive material or adapted wire brushes and sandpaper.

These tools have a low upfront cost and may be sufficient to deburr a handful of low-precision parts. However, they aren’t uniform and may only last 20 minutes each. Plus, results will differ from one employee and handmade tool to another. It’s difficult to measure how this method “performs” because performance is dependent on the individual. This method and these tools tend to lead to scrap, rework and inconsistent quality.

Learn more about the ROI of automated deburring versus manual. >>

If you want to maintain manual deburring processes, consider one of Xebec’s hand-deburring tools. They’re safer, more efficient and produce higher-quality parts than hand-made alternatives and other similar tools on the market.

Grinding Wheels and Flap Disks for Deburring

These are abrasive, circular discs of varying composition attached to handheld or stationary grinders or pneumatic tools.

These methods may take less time and be slightly more uniform than a DIY handheld option, and thus may be the economical choice for small, low-precision jobs. However, they still require the full attention and manual labor of an employee and results will still differ from one employee to another. This is another method that “performs” only according to the performance of the individual, with inconsistent outcomes, scrap and rework.

Additionally, it’s difficult to determine which abrasives are in the discs and anticipate what results they’ll achieve with various part materials. And these tools and methods, as well as DIY handheld options, pose more safety risks and hazards.

Automated Wire Brushes in a CNC Machine

These are wire brushes, typically either steel, stainless steel or brass, automated in the deburring and finishing process.

These could be cup style brushes or wheel brushes. Wire is a good choice for low-intensity deburring projects and comes at a low upfront cost. Automating the process does make this option faster than manual options. However, it’s not a long-lasting tool, it deforms over time, it won’t be effective on harder metals and it grinds slower than abrasive options.

Automated Nylon Brushes in a CNC Machine

These are nylon brushes automated in the deburring and finishing process.

These could also be cup or wheel style. These are cost-effective up-front and can handle harder metals than wire brushes. They can be used to achieve certain edge radiuses and to finish surfaces. However, their performance is inconsistent, takes longer than a ceramic fiber brush and may leave a surface residue. Additionally, the nylon fibers deform over time, meaning a shorter tool life and incrementally reduced quality. And the material isn’t capable of deburring certain smaller bore sizes.

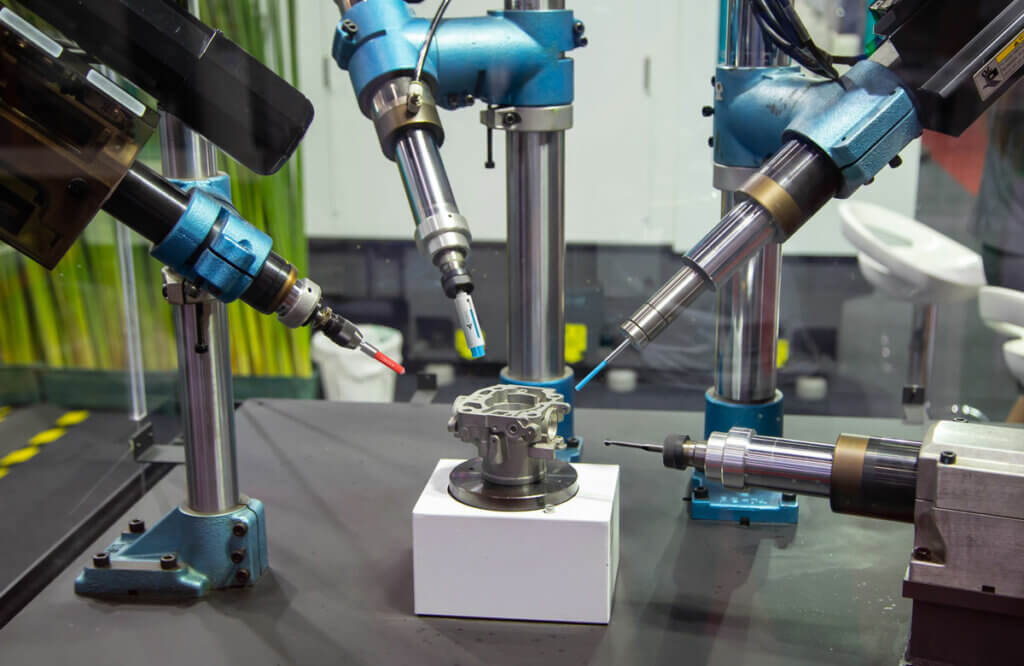

Automated Xebec Ceramic Fiber Brushes in a CNC or Robot

These are Xebec ceramic fiber brushes automated in the deburring and finishing process.

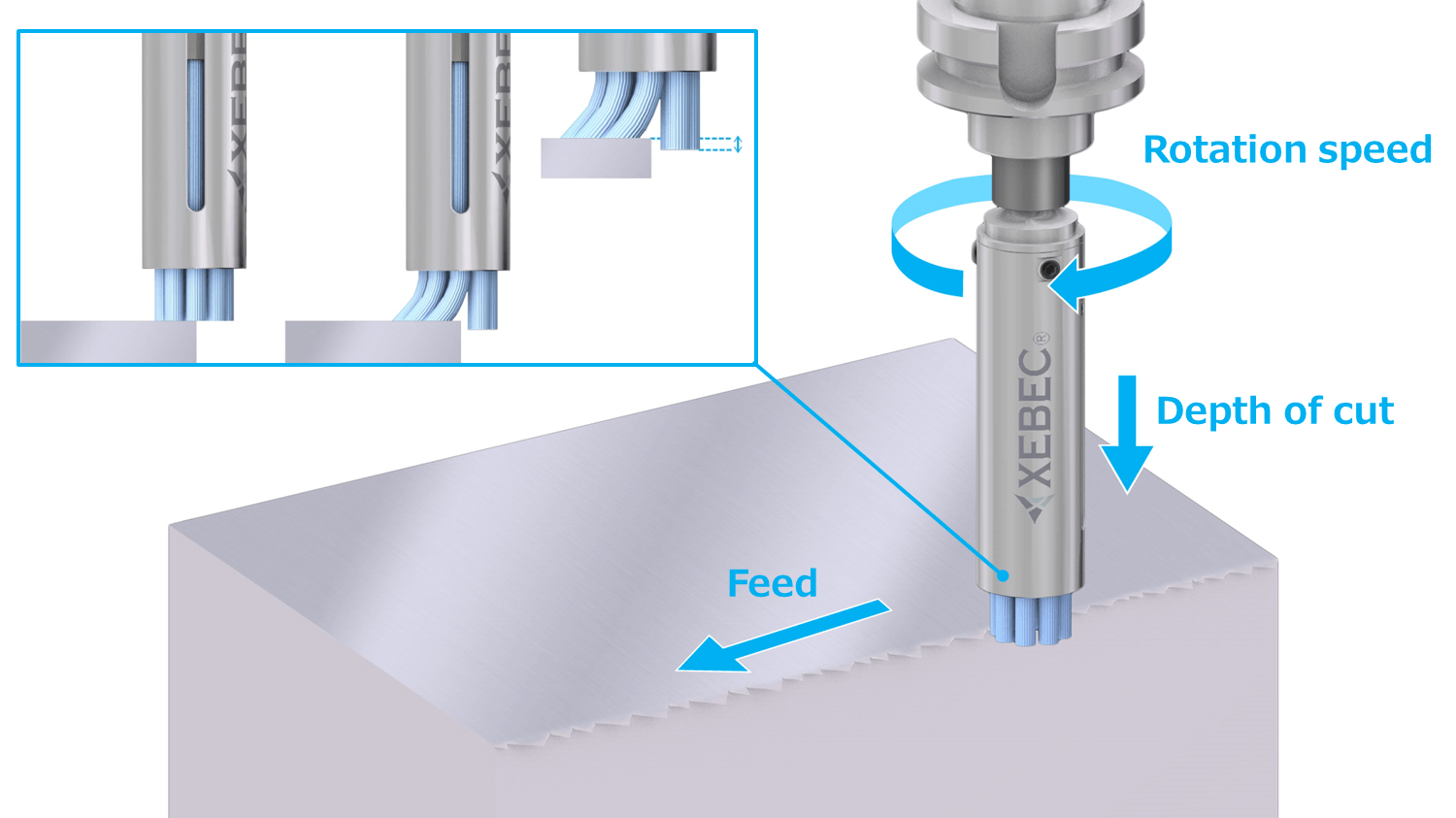

These also come in cup and wheel styles, as well as end type styles and specific designs for crosshole deburring. These brushes are made with continuous ceramic fiber, which has incredible grinding power and produces more parts per tool compared to nylon brushes. In fact, this brush has 60 times the grinding power of nylon brushes.

With this ceramic fiber, the brush performs more like a cutting tool than a brush. It can handle harder metals and is pure, with minimal binders or fillers, so you’re not working with mystery abrasives.

These deburring tools come at a higher price point initially, but they don’t deform over time the way nylon fibers and wire brushes do and they have a significantly longer life. They achieve consistent, high quality with each job and they’re faster than all the other options discussed here. They also finish at the same time as they deburr. Other brushes can’t achieve the quality and productivity levels of these brushes, instead costing you over time. And though automating the process adds machine cycle time, the efficiency and speed of these products repeatedly saves net production time for manufacturers.

Which is the Right Deburring Tool for Your Job?

The best tool for your operations depends on just that – your operations. If you only need to deburr parts every now and then in small quantities, and if you’re not working with high-precision parts for industries like medical, aerospace, firearms and more, you might do just fine with grinding wheels and flap disks on pneumatic tools.

However, if you need to deburr and finish regularly and you’re working with harder materials with higher expectations for spec and quality, you want a brush that truly performs. Though the Xebec ceramic fiber brush comes with a higher upfront cost than other options, its grinding power, speed and performance is such that other brushes don’t even compare.

With these tools, manufacturers have been able to achieve broader goals for their businesses, such as:

To evaluate whether a Xebec ceramic fiber brush is the right tool for you, reach out to discuss your process with one of our experienced, knowledgeable team members.

Download now: A Guide to Choosing the Right Tool, Optimizing Performance and Maximizing Tool Life

Imagine the difference Xebec tools could make at your shop – and make it a reality. We’ve already made the case for you in our free brochure.

2 thoughts on “Xebec Ceramic Fiber Brush: The Deburring Brush that Performs Like a Cutting Tool”

Send me 15 mm diameter ceramic fibar brush with slive

Email your Customer Service Representative at sales@deburringtechnologies.com to place an order.