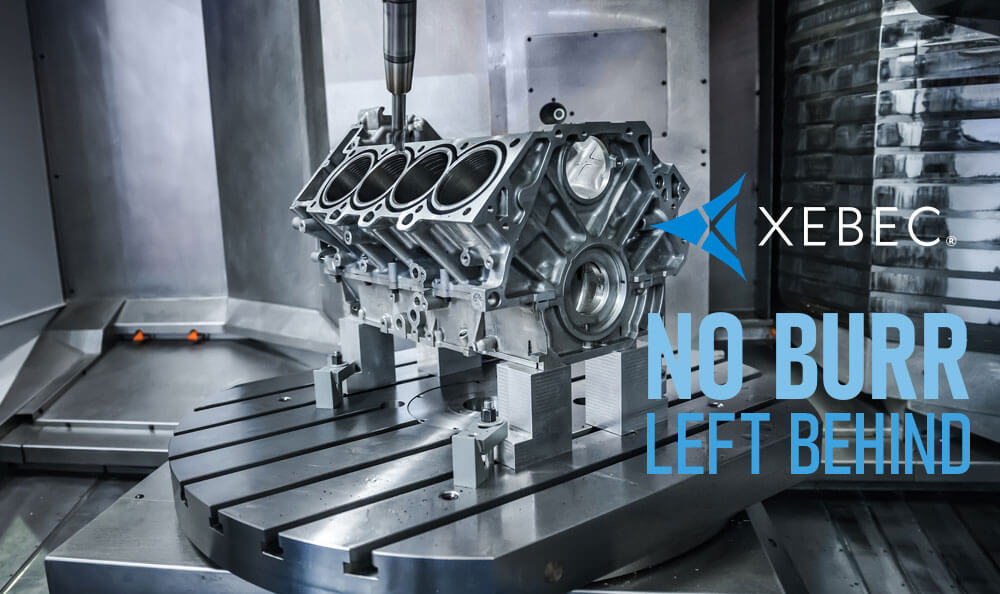

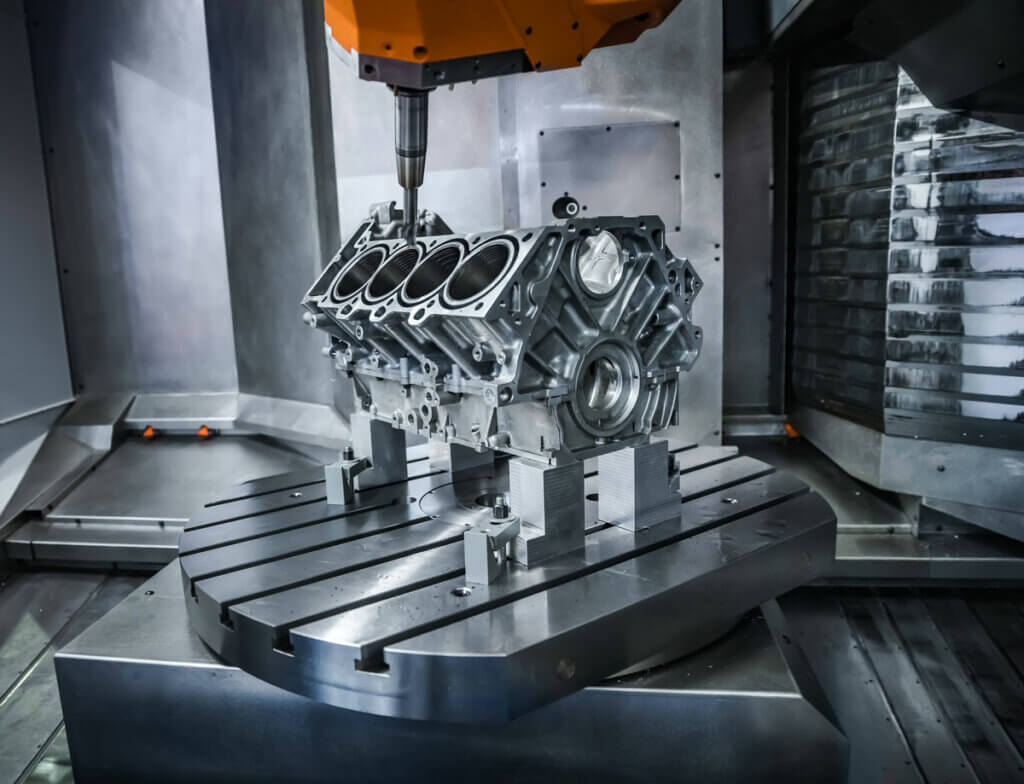

The powertrain industry can reduce burr formation with Xebec for better production output, quality consistency and safety….

Xebec Advantage

Xebec modern deburring and finishing tools help manufacturers and CNC machine shops improve efficiency and quality….

Some issues that come up at a manufacturing organization have cut-and-dry solutions, while others don’t. For instance, equipment break downs are a nuisance and can cause costly downtime, but it’s a knowable issue with a defined solution: repair or…

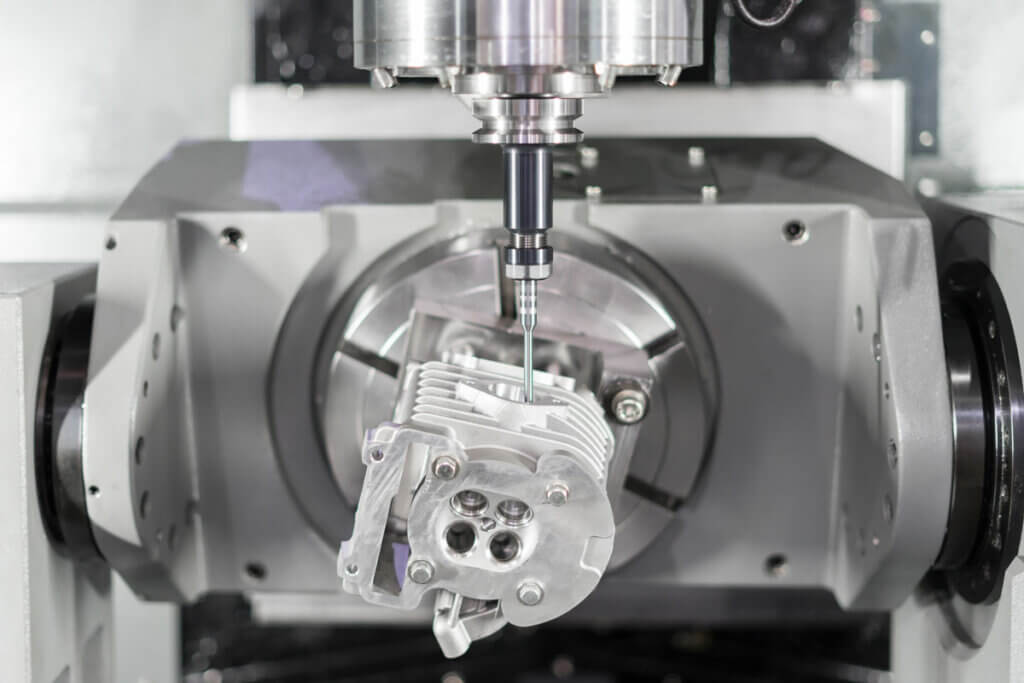

Xebec Deburring Technologies offers the best cutting tool for finishing and deburring for to meet the critical specifications of aerospace and defense industries. …

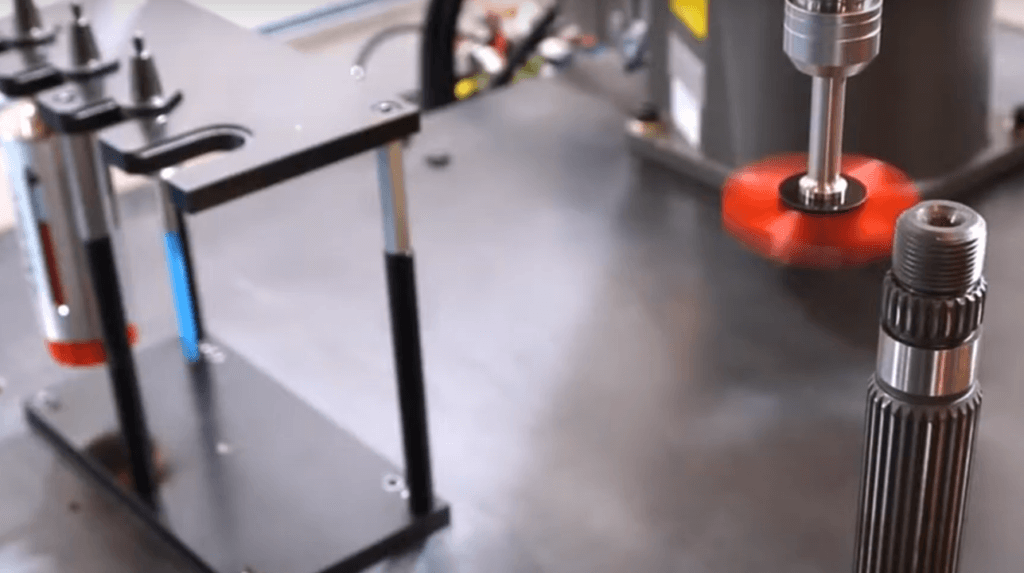

Improve machine shop productivity by thread deburring with Xebec ceramic fiber brushes. Contact IPT America to learn about our thread deburring tools….

Xebec Deburring Technologies can help you resolve deburring and finishing issues: inconsistencies, rework and scrap. Call us today to see how we can help at 800-306-5901….

Manufacturers and machine shops have a plethora of options for deburring and finishing metal parts. However, choosing the right option for your operations is key to meeting expectations for spec, quality, timing, tool wear, and more….

Automated XEBEC ceramic fiber brushes make deburring and polishing a one-step process….

How to Optimize Performance and Maximize Tool Life of your Xebec Deburring & Finishing Brushes…

Improve job costing and production at your CNC machining center by automating deburring and finishing with Xebec Deburring Technologies. For more info contact us at (800) 434-9775….

Be the Hero for your company by making the case for automated deburring by Xebec. Don’t let fear drive business – modernize to save time and money….

Invest in automated deburring and finishing tools by Xebec to improve metalworking safety and eliminate machine shop safety hazards….

Build resilience and liquidity with Xebec deburring tools that improve your deburring and finishing operations with increased productivity and consistent quality….

Xebec deburring tools can help meet sustainability goals and improve the quality, consistency and productivity of your deburring and finishing operations….

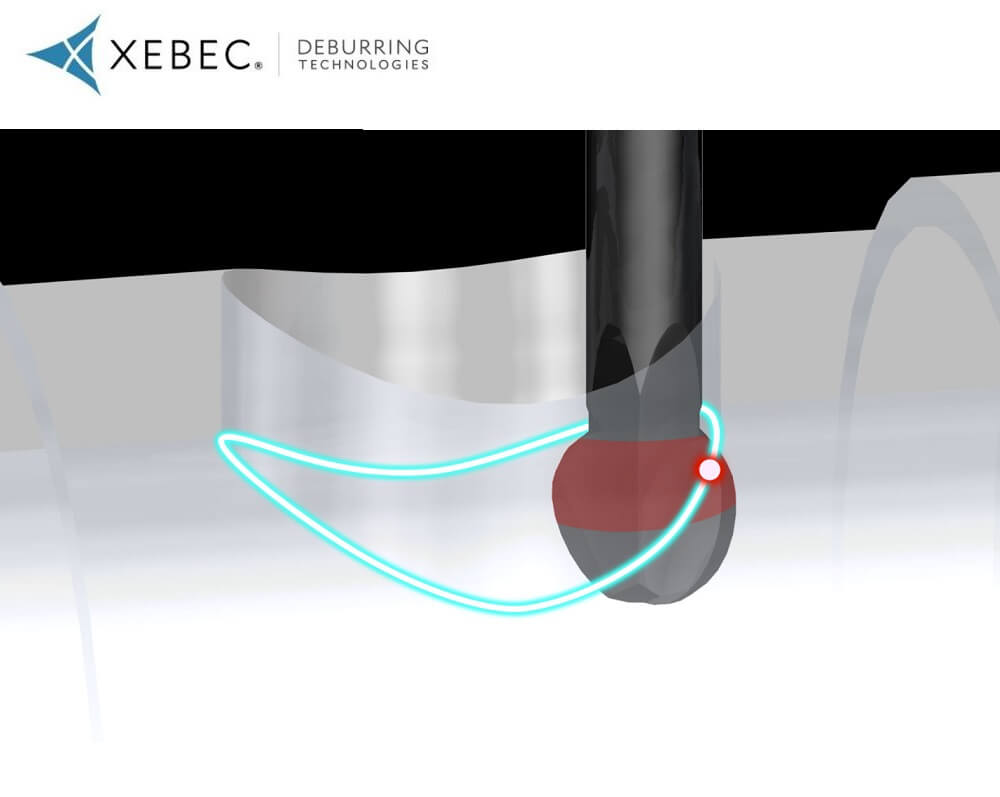

Knowing how to identify the type of burr produced helps in figuring out the best way to remove it. You can count on help from the deburring experts at Xebec Deburring Technologies….

The future of CNC machining is coming at light speed. With Xebec deburring and finishing tools, you’ll be able to provide high-quality work and stay competitive and profitable….

Achieve specific Ra & high-quality finishes on your aerospace turbines and automate with Xebec ceramic fiber deburring and finishing tools….

Xebec has back deburring of complex edge profiles, curved holes and 3D cross holes down to a science with ceramic fiber brushes for lights out manufacturing. …

Xebec has deburring and finishing down to a science and the right fixturing is critical for meeting client specifications and maintaining your reputation for excellence. …

Xebec has deburring and finishing down to a science – whether you need manual tools for detailed finishes or automated ceramic fiber brushes for lights out manufacturing. …