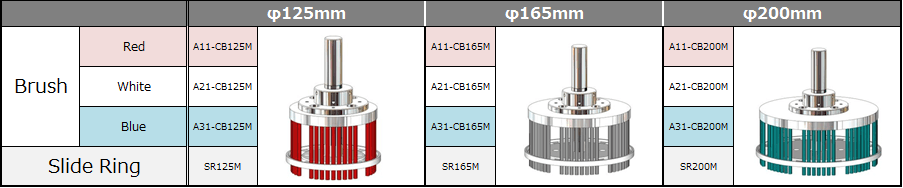

Products

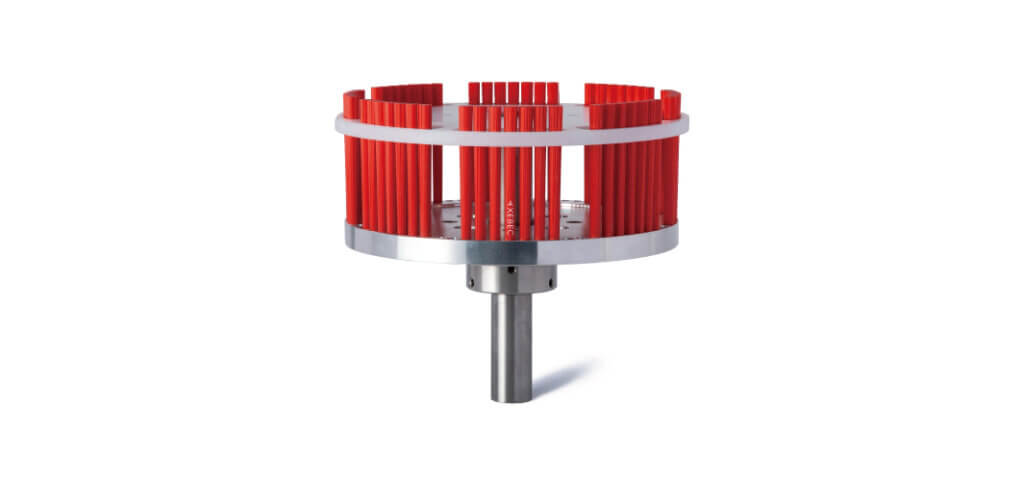

XEBEC Brush™ Surface Extra-Large

XEBEC Brush™ Surface Extra-Large

For machine deburring, cutter mark removal and surface polishing of parts with a surface width of 4 inches or greater.

Note: Brush requires a reusable Brush Ring to operate. Sold Separately.

Tool Dimensions Shown: Metric

Inch

Color

EDP

D3 Brush Diameter (mm)

L4 Brush Length (mm)

Max RPM

Product Number

List Price

Red

30025

125

102

1,000

A11-CB125M

$1,941.62

Red

30028

165

102

750

A11-CB165M

$2,874.24

Red

30031

200

102

600

A11-CB200M

$3,411.73

White

30026

125

102

1,000

A21-CB125M

$1,941.62

White

30029

165

102

750

A21-CB165M

$2,874.24

White

30032

200

102

600

A21-CB200M

$3,411.73

Blue

30046

125

102

1,000

A32-CB125M

$1,941.62

Blue

30047

165

102

750

A32-CB165M

$2,874.24

Blue

30048

200

102

600

A32-CB200M

$3,411.73

Color

EDP

D3 Brush Diameter (in)

L4 Brush Length (in)

Max RPM

Product Number

List Price

Red

30025

4.921

4.016

1,000

A11-CB125M

$1,941.62

Red

30028

6.496

4.016

750

A11-CB165M

$2,874.24

Red

30031

7.874

4.016

600

A11-CB200M

$3,411.73

White

30026

4.921

4.016

1,000

A21-CB125M

$1,941.62

White

30029

6.496

4.016

750

A21-CB165M

$2,874.24

White

30032

7.874

4.016

600

A21-CB200M

$3,411.73

Blue

30046

4.921

1,000

A32-CB125M

$1,941.62

Blue

30047

6.496

750

A32-CB165M

$2,874.24

Blue

30048

7.874

600

A32-CB200M

$3,411.73

XEBEC Brush Ring

Tool Dimensions Shown: Metric

Inch

Size

EDP

D1 Shank Diameter (mm)

D2 Ring Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

Product Number

List Price

125

SR125M

25

135

175

65

40010

$748.17

165

SR165M

25

176

175

65

40011

$843.76

200

SR200M

25

211

175

65

40012

$909.38

Size

EDP

D1 Shank Diameter (in)

D2 Ring Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

Product Number

List Price

4.921

SR125M

0.984

5.315

6.89

2.559

40010

$748.17

6.496

SR165M

0.984

6.929

6.89

2.559

40011

$843.76

7.874

SR200M

0.984

8.307

6.89

2.559

40012

$909.38

How to Select

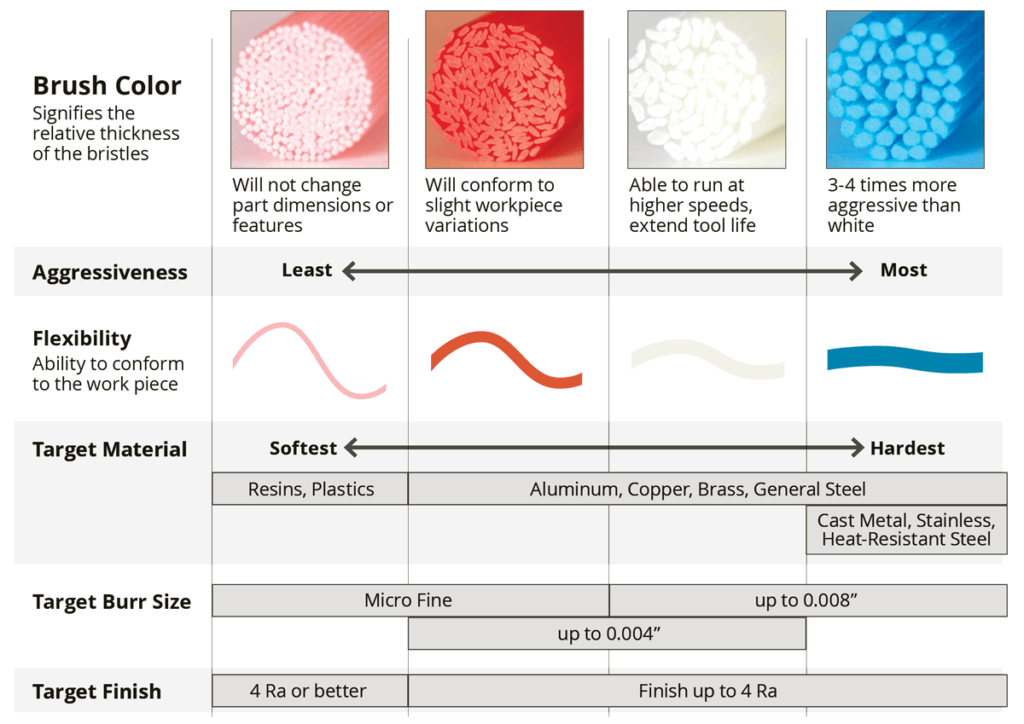

Grinding power differs depending on brush color. All Xebec brushes are made from the same proprietary ceramic fibers manufactured into rods, or bristles, of different thicknesses. The greater the bristle thickness, the more aggressive the cutting action. Refer to the chart below and select brush color based on the workpiece material and burr root thickness.

How to Choose Brush Color

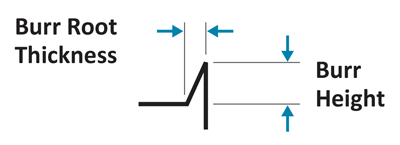

Target Burr Size

Burr Root Thickness of 0.008” or less (Burrs can be bent with a fingernail)

How to Choose Brush Size

Select a brush size based on workpiece size and shape, interfering objects such as jigs, attachable tool length and cycle time.

It is recommended to use a brush size which is 1.5 to 2 times wider than the width of the surface of the workpiece. This allows the brush to engage the edge at 90 degrees for optimal grinding power. Using a larger brush than the surface width will also require the fewest number of passes and minimize cycle time.

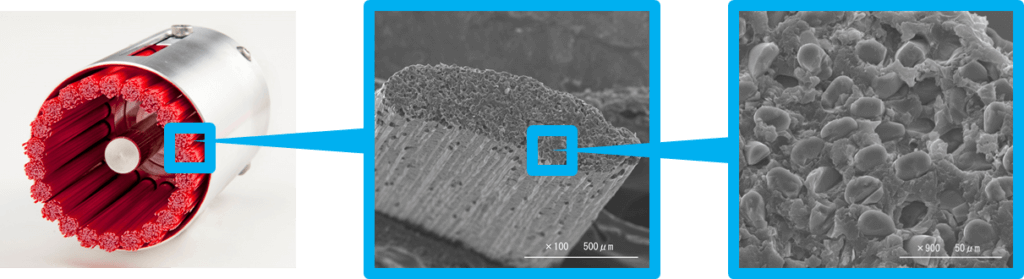

Strucutre of Xebec Ceramic Fiber

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

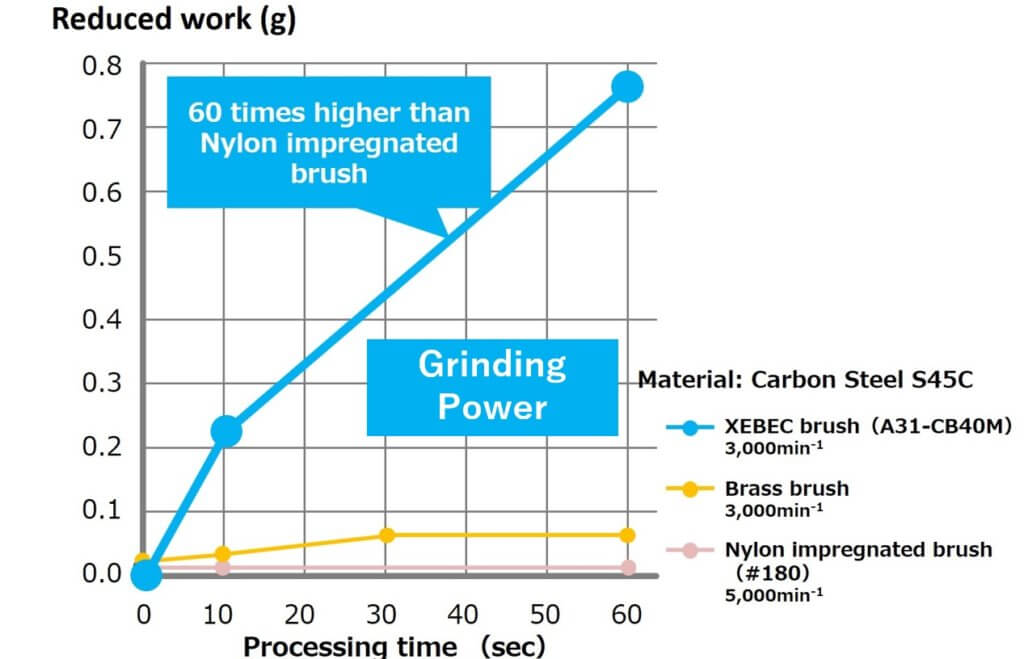

Strength 1: Unsurpassed Grinding Power

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

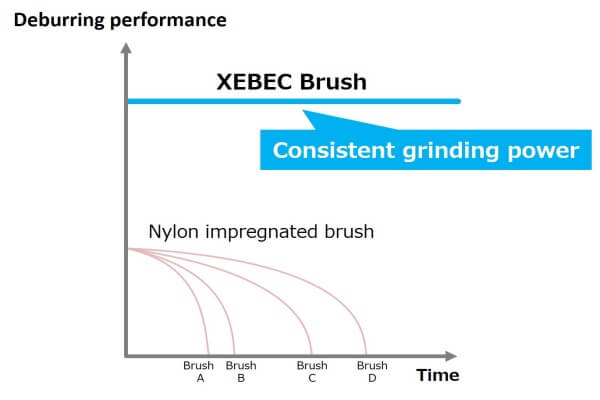

Strength 2: Consistent Grinding Power to the End

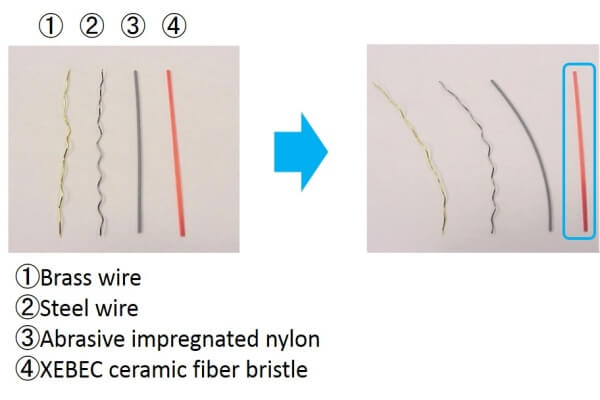

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

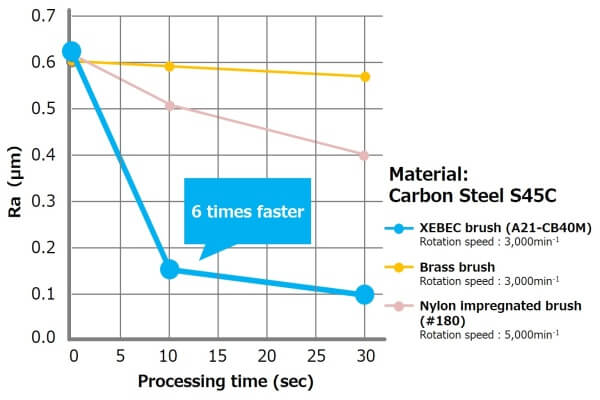

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Target

Intended for workpiece edges with a width of 100mm or greater, such as cylinder heads, cylinder blocks, and machinery tables and heads. This brush is ideal to reduce machining time by decreasing the number of passes and improve finish quality by minimizing laps.

XEBEC Brush™ has high grinding power on the tip, so the tip of the brush must be applied directly to burrs. Both vertical and horizontal burrs after milling or drilling can be removed. It should not be used on protruding object because it may cause brush breakage.

Applicable Equipment

It is necessary to control the rotation speed to use XEBEC Brush™. The tool can be used on machining centers, combined lathes, robots, special machines, and driling machines.

Required torque for maximum rotation speed is:

Φ125mm:25N・m; Φ165mm:45N・m; Φ200mm; 65N・m (rough standard)

Torque changes based on the proportion of brush interacting with the workpiece, the depth of cut, and the length of the brush.

Selection

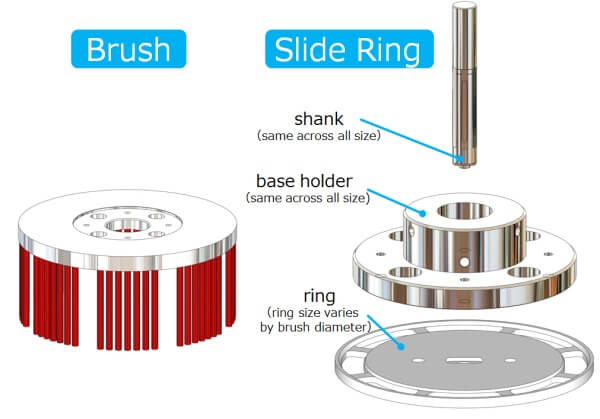

Product Structure

A brush and slide ring are a separate items. Assemble the brush and slide ring before use. The slide ring consists of a shank, base holder, and ring. Each component is available individually.

*Brush, base holder, and ring contain the following items:

- Brush: 4 screws (M5 cap screw), hex wrench

- Base holder: 3 screws (M5 hollow set), hex wrench

- Ring: 1 screw (M5 low cap screw), 1 flat washer, hex wrench

*The ring is a consumable item. Replace the attached point with the new one if it is worn out or if the attached point becomes loose

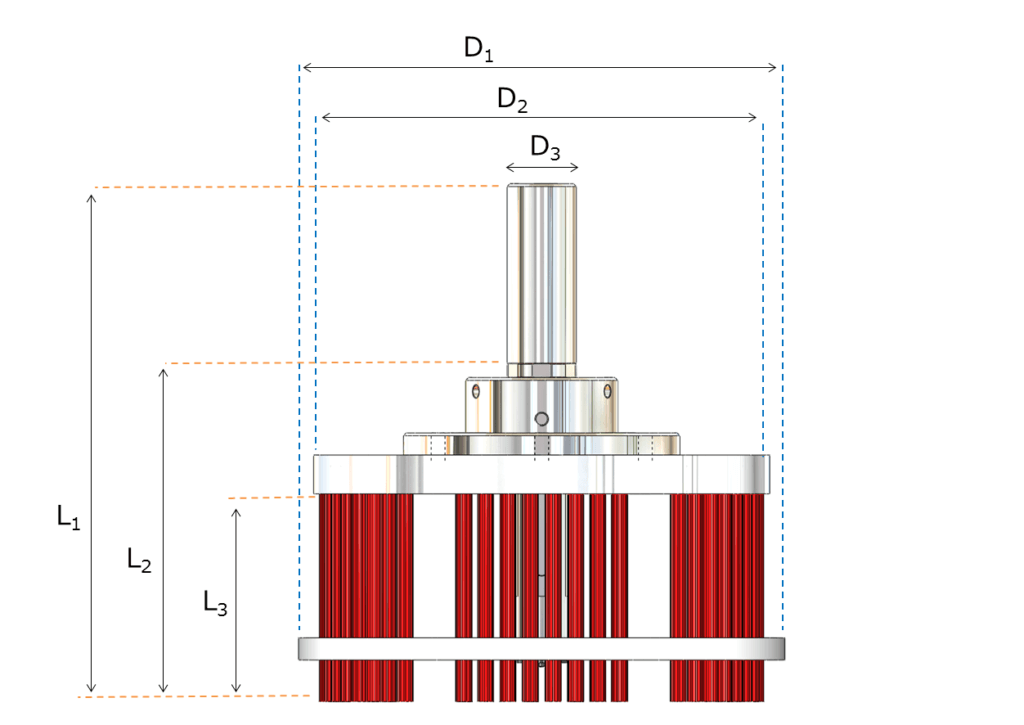

Tool Schematic

Brush Diameter (MM)

L1 (MM)

L2 (MM)

L3 (MM)

D1 (MM)

D2 (MM)

D3 (MM)

Weight (G)

Φ125

Φ165

Φ200

187

122

75

135

176

211

125

165

200

25

1920

2320

2750

Processing Conditions

Deburring

Brush Diameter

Depth of Cut D (MM)

Vertical Burrs

Horiztontal Burrs

Rotation Speed S (Min-1)

Recommended

Maximum

Feed Rate F (MM/Min)

Burr Root Thickness 0.05MM

Burr Root Thhickness 0.1MM

Brush Projection (MM)

Φ125

0.5

1.0

800

(MAX1000)

4,000

2500

15

Φ165

0.5

1.0

600

(MAX750)

4,000

2500

15

Φ200

0.5

1.0

480

(MAX600)

4,000

2500

15

If burrs remain

- Increase the rotation speed in 25% increments. Be aware of the maximum rotation speed.

- Decrease the feed rate in 10-20% increments.

To extend tool life / If the edge is too rounded

- Decrease the rotation speed in 25% increments.

- Increase the feed rate in 10-20% increments.

If the brush is worn out unevenly

- Double the feed rate F and process the workpiece using the round pass.

- Rotate the brush in a counterclockwise direction for the return pass.

Cutter Mark Removal & Polishing

Brush Diameter

Depth of Cut D (MM)

Cutter Mark Removal

Polishing

Rotation Speed S (Min-1)

Recommended

Maximum

Feed Rate F (MM/Min)

Cutter Mark Remove & Polishing

Brush Projection (MM)

Φ125

0.5 - 1.0

0.3 - 0.5

800

(MAX1000)

300

15

Φ165

0.5 - 1.0

0.3 - 0.5

600

(MAX750)

300

15

Φ200

0.5 - 1.0

0.3 - 0.5

450

(MAX600)

300

15

If cutter marks are not removed

- Increase the number of passes.

- Increase the rotation speed in 25% increments. Be aware of the maximum rotation speed.

To extend tool life / If the edge is too rounded

- Decrease the rotation speed in 25% increments.

- Increase the feed rate in 20-40 % increments.

If the brush is worn out unevenly

- Double the feed rate F and process the workpiece using the round pass.

- Rotate the brush in a counterclockwise direction for the return pass.

No, it does not. The ceramic fibers work as abrasive materials.

For the cup type, attach the shank of the sleeve to an automatic tool changer (ATC) on a machining center or other equipments. Then rotate the tool and remove burrs after cutting work on machine. It can also be used with robots, special machines and drilling machines.

For the end type, attach the tool to an electric tool (or machine tool). It can not be used with a pneumatic tool.

The tool aims to remove burrs with the size that can be bent by pushing one’s fingernail against it.

The cup type brush can be used for chamfering or rounding an edge.

The tool can be used for both dry and wet (both oil-based and water-soluble) machining.

Wet machining may improve surface finish quality and tool life.

XEBEC Brush™ does not define the grits. It is capable of finishing the surface up to around Ra=0.1μm.

Tool life significantly varies depending on machining conditions, burr condition (size and direction) and workpiece material.

In one case study, where the tool was used for deburring after milling of an oil pan with 1m circumference (material:aluminum), a single brush lasted for 10,000 workpieces (straight line distance of 10,000m=10km)

Example:

Workpiece: Oil Pan (automotive engine part)

Material: Aluminum

Cutting process: 1m / piece

Result: 10,000 workpieces / brush (total length 10km)

Remove the attached dust or coolant by blowing air, etc.

You can form a brush using a diamond disc blade.

Yes, it is possible. XEBEC’s genuine parts are recommended. Contact us for the details.

The inner part of the tip of the sleeve is worn out and become thinner as it is gradually ground by the sides of the brush over a long period of use. Replace the sleeve.

It is possible to purchase the outer cylinder of the sleeve alone. Contact us for the details.

Yes, we provide services such as extension of bristle length and modification of the brush tip shape. Please contact us for more information.