Products

Application Guide

Find the best product for your job

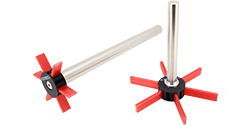

Surface Deburring & Finishing Tools

Product

Applications

Features

- Fine deburring

- Surface finishing

- Use on wide variety of materials

- Ideal for simultaneously deburring & finishing edges

- Continuous cutting edge provides consistent grinding performance

- Fine deburring

- Surface finishing

- Use on wide variety of materials

- Minimize cycle time by reducing number of passes

- Suitable for deburring & polishing workpieces with a width ≥ 100mm

- Fine deburring

- Surface finishing

- One color for all materials

- Ideal for deburring & polishing of side surfaces and inner diameters

- Suitable for deburring of internal & external threads

- Fine deburring

- Surface finishing

- One color for all materials

- Applies more consitent pressure to tool

- Enhances brush performance

- Reduces machine time

- Extends tool life

- Automated brush adjustment

- Uses rack and gear for automated in-machine adjustments

- Lights-out solution for setting brush projection

- Great for long runs, large parts, and un-manned operations

- Brush length adjustment

- Set brush projection

- Quick in-machine brush length adjustment

- Brush rest and measurement scale

- Adjustment knob and fixing nut

Crosshole Deburring & Finishing Tools

Product

Applications

Features

- Deburring holes

- Inner and outer edges

- Elliptical holes

- Variety of edge profiles

- Optimal path is programmed by Xebec

- Micro-grain cemented carbide cutter with heat-resistant AlTiCrN coating

- Faster operating time thanks to the unique cutter design

- Entirety of the cutting blade is used providing a longer tool life

- Consistent deburring amounts result in a uniform edge shape

- Edge deburring

- Deep counterbored part

- Inner wall polishing

- Variety of edge profiles

- Ideal for horizontal holes or deep parts

- Both deburring & polishing without scratching an inner wall

- Edge deburring

- Rounded surface polishing

- Blind hole

- Flexible shaft allows soft contact with workpiece

- Ideal for deburring and polishing

Detailed Finishing Tools:

Product

Applications

Features

- Polishing curved surface

- Toolmark removal

- Removing oxcide layer

- Ideal for flat and curved surface by preventing undulation

- Suitable for both deburring and polishing

- Edge deburring

- Remove partition line

- Can be used at high rotation speed

- Ideal for deburring and polishing

- Mold polishing

- Edge deburring

- High grinding power on the entire surface

- Easy to form the tip

- Mold polishing

- Edge deburring

- Removing scratches

- No breaking, no cracking, no chipping

- For materials up to HRC57

- Diamond type for materials above HRC57

- Fine deburring

- Deburring narrow parts

- Deburring slit part

- Ideal for small and narrow parts

- Suitable for both deburring and polishing

- Manual deburring

- Finishing & polishing

- Rechargeable Li-Ion battery

- Use with XEBEC Stone™ Flexible Shaft

- Use with XEBEC Brush™ Surface End Type

- Use with XEBEC Stone™ Mounted Point

- Use with XEBEC Ceramic Stone™ Meister Finish Rod Type

Test Tool Policy

Due to the unique design of XEBEC products, we have achieved optimal success when Deburring Technologies technical personnel assist in the selection of proper tool and operating parameters. Provided our representative has reviewed an application and provided processing recommendations, we are pleased to provide reasonable quantities of test product with a “Guaranteed Trial” purchase order. Such product will be invoiced and is payable per our normal NET – 30 DAY terms. Should the product not perform as promised, simply contact us for a return authorization within forty five (45) days of purchase with a written report of how the product failed to meet the promised performance. Once we have received and inspected the product we will issue full credit for the returned product. All returns for other than guaranteed trial performance must be received within thirty (30) days from date of purchase and be received in new condition in the original packaging. Once we have received and inspected the product we will issue full credit for the returned product.