Products

XEBEC Brush™ Wheel Type

XEBEC Brush™ Wheel Type

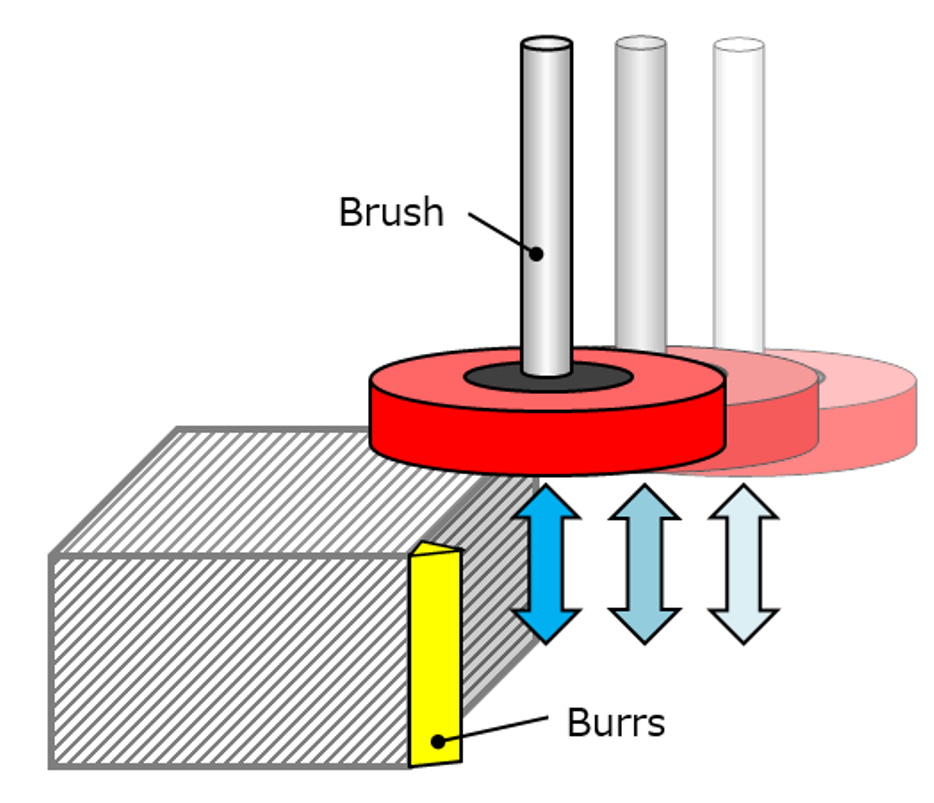

For deburring and polishing of side surfaces and inner diameters in CNC machine. Cutting tips approach from the side.

Note: Brush requires reusable Shank to operate. Sold Separately. Two lengths available, all sizes compatible.

Tool Dimensions Shown: Metric

Inch

EDP

Size

D2 Head Diameter (mm)

D3 Brush Diameter (mm)

L3 Head Thickness (mm)

L4 Brush Height (mm)

Max RPM

Product Number

Price

60007

50

23

50

9.6

8

3,000

W-A11-50

$224.18

60008

75

23

75

9.6

8

3,000

W-A11-75

$269.98

EDP

Size

D2 Head Diameter (in)

D3 Brush Diameter (in)

L3 Head Thickness (in)

L4 Brush Height (in)

Max RPM

Product Number

Price

60007

1.969

0.906

1.969

0.378

0.315

3,000

W-A11-50

$224.18

60008

2.953

0.906

2.953

0.378

0.315

3,000

W-A11-75

$269.98

XEBEC Shank for Wheel Brush

Tool Dimensions Shown: Metric

Inch

Shank (mm)

EDP

D1 Shank Diameter (mm)

Product Number

Price

70 mm Shank

60009

8

WSM

$45.77

150 mm Shank

60010

12

WSL

$50.52

Shank (in)

EDP

D1 Shank Diameter (in)

Product Number

Price

2.756 in Shank

60009

0.315

WSM

$45.77

5.906 in Shank

60010

0.472

WSL

$50.52

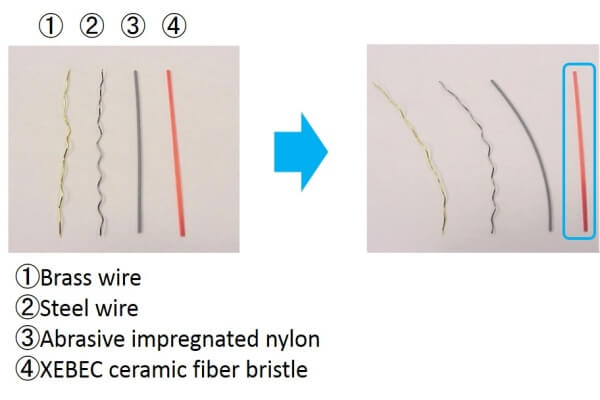

Strucutre of Xebec Ceramic Fiber

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Unsurpassed Grinding Power

- Consistent Cutting Performance

- No Deformation

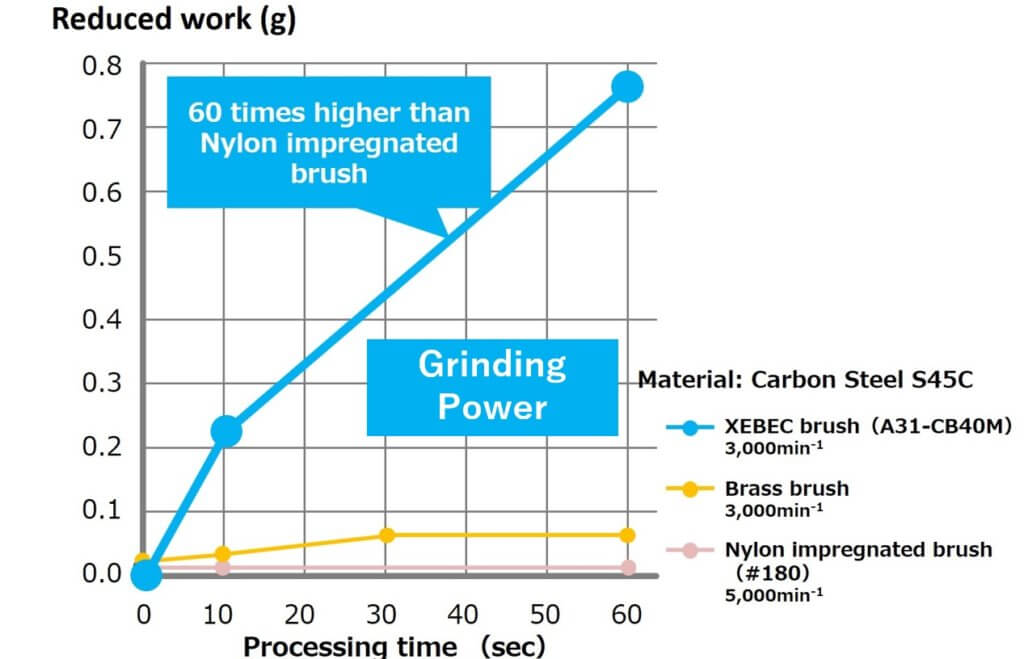

Strength 1: Unsurpassed Grinding Power

Our uniquely developed ceramic fibers themselves are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create unsurpassed grinding power.

XEBEC Brush™ has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

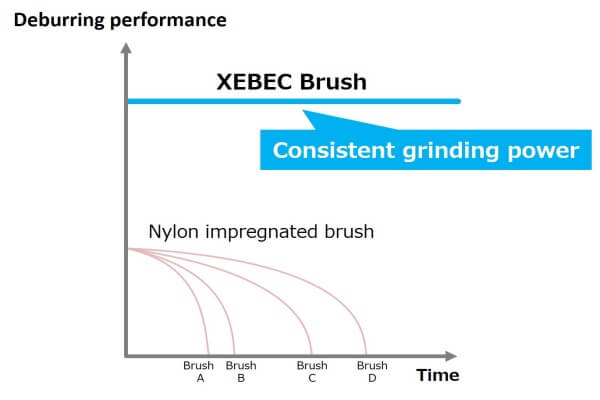

Strength 2: Consistent Grinding Power to the End

Strength 3: No Deformation

XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

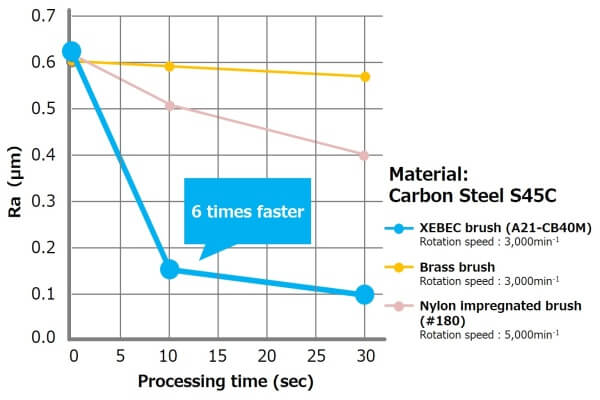

Amazing Polishing Power

XEBEC Brush™ is made of ceramic fiber bristle which was developed for mold polishing. Its high grinding power improves surface roughness in a short time.

Best achievable surface roughness Ra=0.1μm (Rz = 0.4μ)

Applicable Equipment

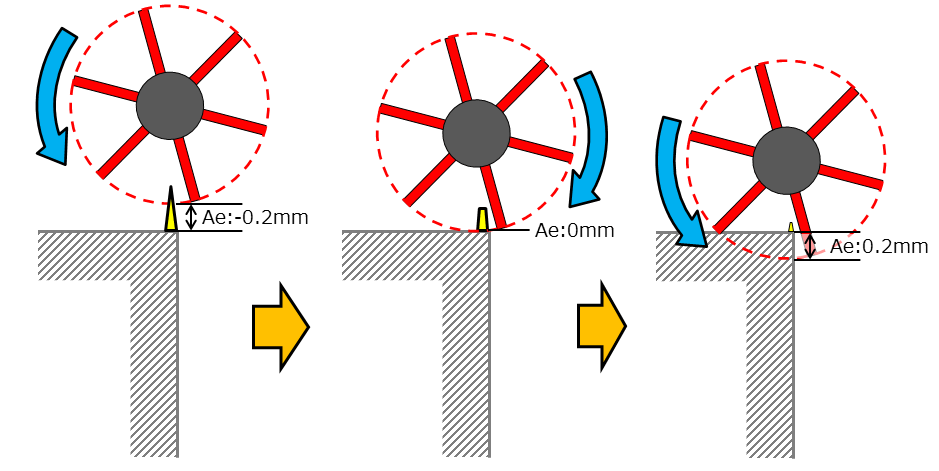

It is necessary to control the spindle speed and the depth of cut to use XEBEC Brush™ Wheel Type.

- Machining center: milling chuck holder, collet chuck holder

- Milling lathe: milling holder for X-axis and Z-axis

- Robot, etc

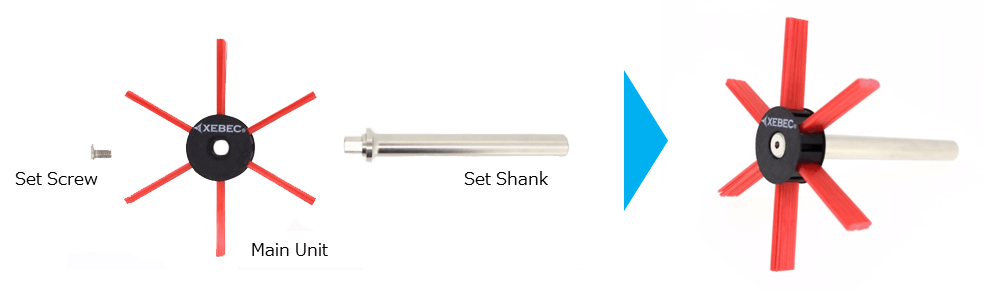

Assembly

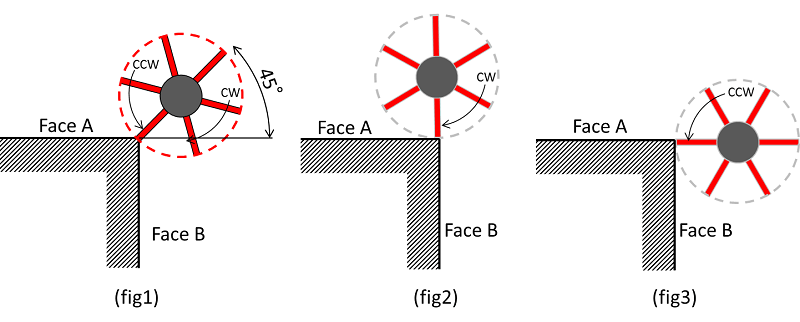

How to Engage

From the top view, the best approach is to place a center of a brush at the center angle to the edge. (Figure 1)

Burrs on Face A and B can be both removed.

Edge quality becomes stable if a brush is rotated in both clockwise and counter-clockwise directions.

Brush position on Figure 2 is effective for burrs on Face A in the same way as Figure 3 for burrs on Face B.

Dry or Wet Machining

The tool can be used for both dry and wet (both oil-based and water-soluble) machining.

Wet machining may improve surface finish quality and too life.

Demo

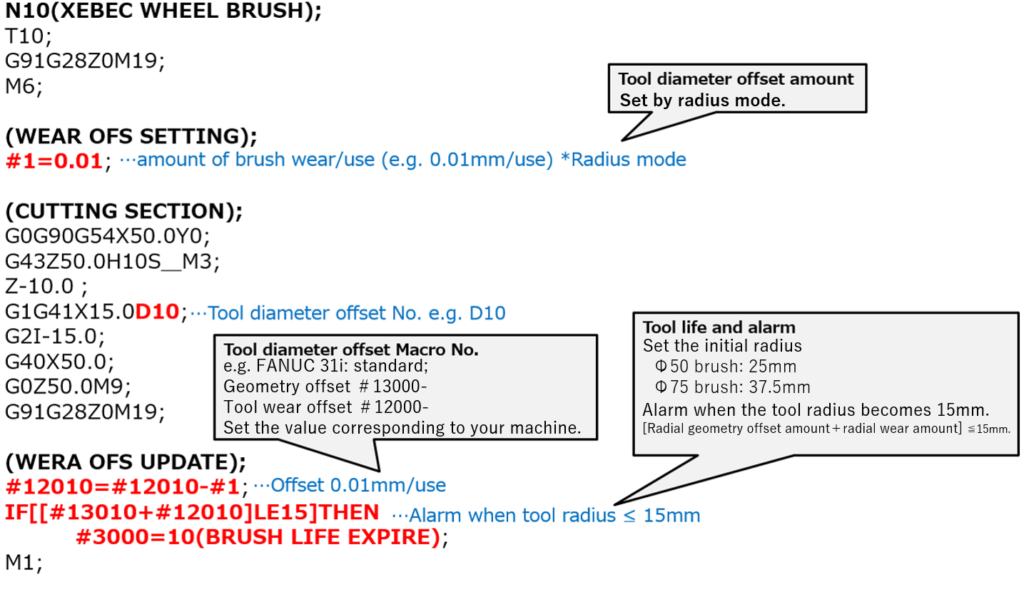

Macro Program

To use the XEBEC Brush™ Wheel Type, the depth of cut must be kept small. It is necessary to offset the wear amount in a radial direction.

Use a macro program or manually offset the wear amount. Refer to the example below.

Initial Process Conditions

Product Code

Cutting Speed (M/MIN)

Spindle Speed (MM/MIN)

Feed Per Bundle (MM/Bundle)

Table Feed (MM/Min)

Depth of Cut (MM)

W-A11-50

250

1600

0.5

4800

0.2

W-A11-75

250

1000

0.5

3000

0.2

Range of Processing Conditions

Product Code

Cutting Speed (M/MIN)

Feed Per Bundle (MM/Bundle)

Table Feed (MM/Min)

Depth of Cut (MM)

W-A11-50

W-A11-75

150 ~ 350

1.5 and under

Less than 1.5*1

3000

*1 As bristles are worn out, bristle length becomes shorter and increases shiftness, causing bristles to be broken. If bristles breakage occurs, decrease the depth of cut.

*The processing conditions differ depending on the state of burrs. Make adjustments according to the quality of the workpiece.

If burrs remain:

- Increase the number of passes

- Then, decrease the feed rate

To extend tool life:

- Increase the feed rate

If burrs are too large:

- Use multiple passes as described below

- Gradually move the brush closer to the bottom of burrs; increase the depth of cut step by step

- Trying to remove burrs in 1 pass may cause excessive tool wear, tool breakage or burrs may not be removed

- Calculate the maximum height of burrs before using the tool