Products

XEBEC Floating Holder™

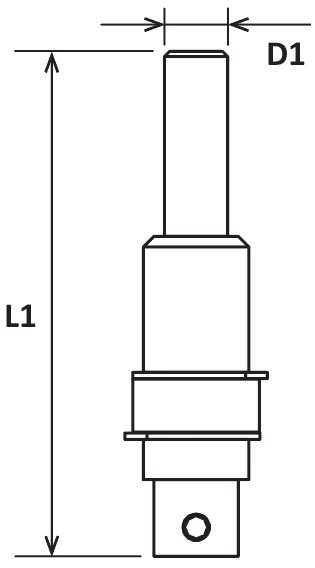

XEBEC Floating Holder™ Straight Shank

Adjustable pressure control using a built-in spring. Provides a more consistent finish and longer brush life for heavy applications.

Tool Dimensions Shown: Metric

Inch

For Brush Diameter (mm)

EDP

D1 Shank Diameter (mm)

L1 Overall Length (mm)

Axial Float

Gage Length

Matching Sleeve (EDP)

Product Number

Price

6 to 40

50002

12

95.5

6

60.5

FH-ST12-SL10

$413.75

60

50006

20

96.4

6

51.5

FH-ST20-60

$1,150.97

100

50005

20

96.4

6

51.5

FH-ST20-100

$1,150.97

For Brush Diameter (in)

EDP

D1 Shank Diameter (in)

L1 Overall Length (in)

Axial Float

Gage Length

Matching Sleeve (EDP)

Product Number

Price

0.236 to 1.575

50002

0.472

3.76

0.236

2.282

FH-ST12-SL10

$413.75

2.362

50006

0.787

3.795

0.236

2.028

FH-ST20-60

$1,150.97

3.937

50005

0.787

3.795

0.236

2.028

FH-ST20-100

$1,150.97

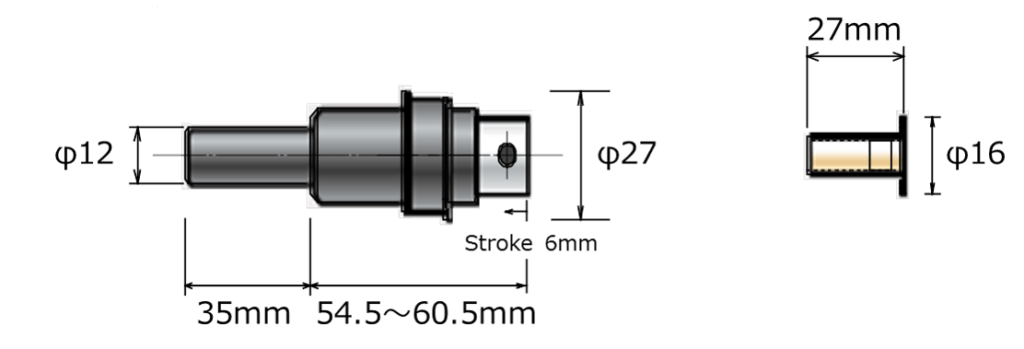

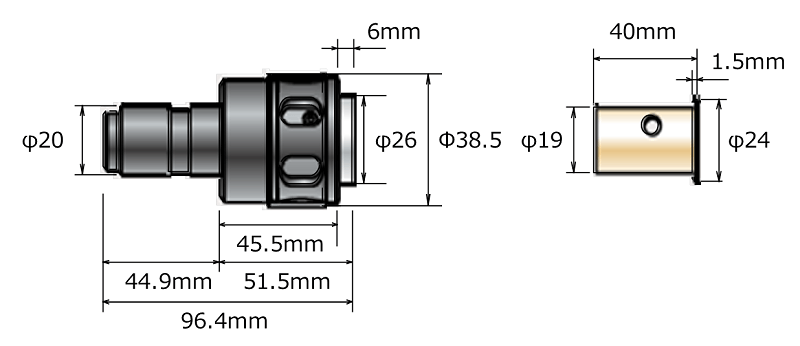

Tool Schematic

FHST12:

FH-ST20:

Applicable Equipment

It is necessary to control the rotation speed to use XEBEC Floating Holder™.

The tool can be used on machining centers, combined lathes, robots and special machines, and drilling machines.

*When attaching the floating holder to a machining center, do not use a pull bolt with through-hole (center through pull bolt). *For horizontal machining center, the floating function may not work if the spring load is low.

Points to Note

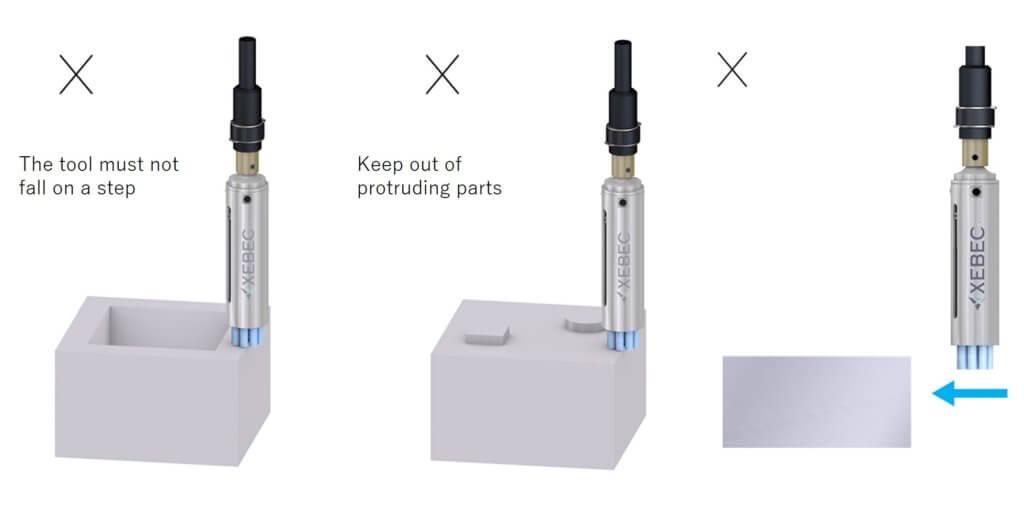

- The tool can basically be used for workpieces that can be processed with XEBEC Brush™ Surface.

- Don't use on intermittent part in which the brush would fall or when there is an obstacle.

- Approach the brush vertically and make it engaged with workpiece. Don't contact the side of the brush because it will cause damage to the bristles.

How to Use

When using the XEBEC Floating Holder™, follow the usage instructions below:

1. Approach the tool from above to the workpiece while not in motion

2. Set the depth of cut and make the spring contracted

3. Rotate the tool and start feeding

4. Stop rotation and feeding of the tool when machining is completed

5. Remove the tool upward

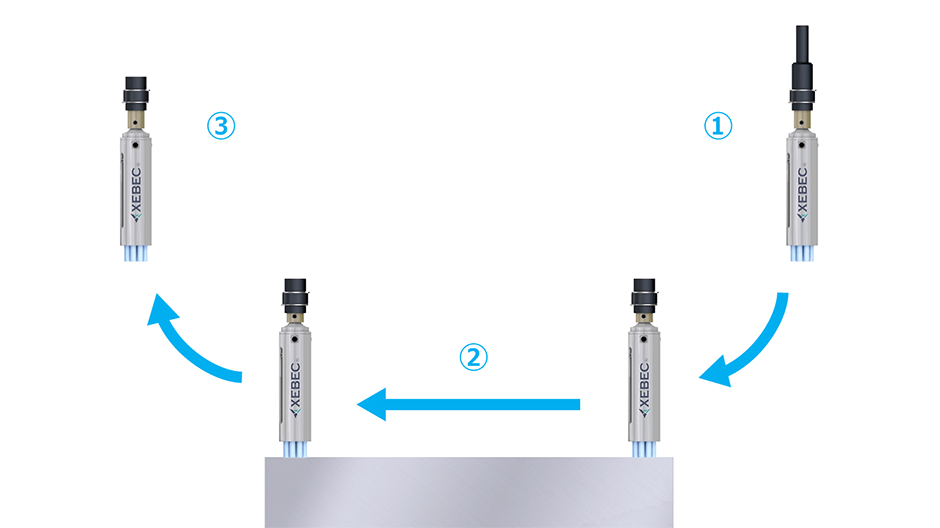

Technical Tips

In order to improve finish quality of the start and end points, follow the usage instruction below:

1. Rotate the brush and approach from above to the workpiece

2. Set the depth of cut, make the spring contracted and then start feeding

3. Remove the tool upward while in motion

No, it is an optional tool. XEBEC Brush™ Surface can be used by itself.

XEBEC Floating Holder™ has the following effects in mass production line:

1. Reduces machining time to adjust the depth of cut and the brush projection amount caused by brush wear (e.g. actual results: reduced by 1/18)

2. Extends tool life (e.g. actual results: extended by 4 times)

3. Stable edge quality

Yes, it can be used for both dry and wet machining. ・For dry processing, use a dust collector to collect the dust that may be generated during the processing. ・For wet processing, the holder shall not be exposed to coolant. ・If dust or coolant gets inside the holder, the floating function will not work. Using with CNC Equipment ・When attaching the floating holder to a machining center, do not use a pull bolt with through-hole (center through pull bolt). If the coolant gets inside the holder, the floating function will not work. ・For horizontal machining center, the floating function may not work if the spring load is low.

For a horizontal machining center, the floating function may not work if the spring load is too weak. For FH-ST12-SL10, use the high-load spring. FH-ST20 can not be used on a horizontal machining center.

Sludge may have entered the tool. Disassemble the tool clean the inside. See the instruction manual for the details.