Most manufacturers and machine shops remove burrs after the chamfering process. In fact, more than 80 percent of our customers follow this method. So, if that’s how your process works, you’re not alone. There haven’t been many options for chamfering tools that eliminate the need for a post-chamfering deburring process.

Until now.

We at Xebec Deburring Technologies are proud to introduce the Xebec Burrless Chamfering Cutter, a chamfer tool that prevents burrs and eliminates the deburring process.

When you eliminate this post-chamfering process, you:

- Reduce labor costs

- Reduce tool costs

- Shorten the cycle time

What is a Chamfer?

For machinists, a chamfer edge is 45-degree cut made on the sharp edge of a workpiece. Chamfering an angled edge eases assembly and is often used to create clearance for joining or connecting parts. Chamfering also removes sharp edges, significantly reducing incidents of cuts and injuries to operators handling the metal piece.

The edge can be the outside of the part, where a hole breaks through a surface or where any two surfaces meet. Typical areas that need chamfering are holes such as the ends of rods, bolts, and pins plus the corners of the long edges of plates of sheet metal.

There are two types of chamfers, Leg Length and Face Width, and differ in the way they are measured. A chamfer differs from a break edge, in that break edge doesn’t need to meet a strict measurement requirement. A countersink is a chamfer applied to a round edge like a hole and radii are a rounded-edge applied to a raw corner rather than a chamfered edge.

For chamfered (and rounded) edges with critical tolerances, machining is the best solution. And as with any cuts to metal and other materials used in manufacturing, any resulting secondary burrs from chamfering must be removed.

Types of parts that need chamfered edges include:

- Engine blocks

- Manifolds

- Golf clubs

- Turbines

- Firearm components

The Xebec Burrless Chamfering Cutter: Key Features and Performance

This chamfering tool offers the world’s first V-shaped blade, a patented technology from Xebec. It’s this blade type that enables the tool to prevent burrs during the chamfering process. It cuts a clean, finished, burr-free chamfer. With this, you can eliminate the deburring process and shorten cycle time – saving on labor and tool costs.

The cutter is designed with multiple blades, which enables a high feed rate and reduced machining time, and a flat tip, which prevents rounding and chipping of the tool.

Our chamfer cutter is made from Micro-Grain Cemented Carbide, and it’s available Coated with a heat-resistant AITiCrN coating or Uncoated with a sharper edge suited for aluminum alloys and plastics.

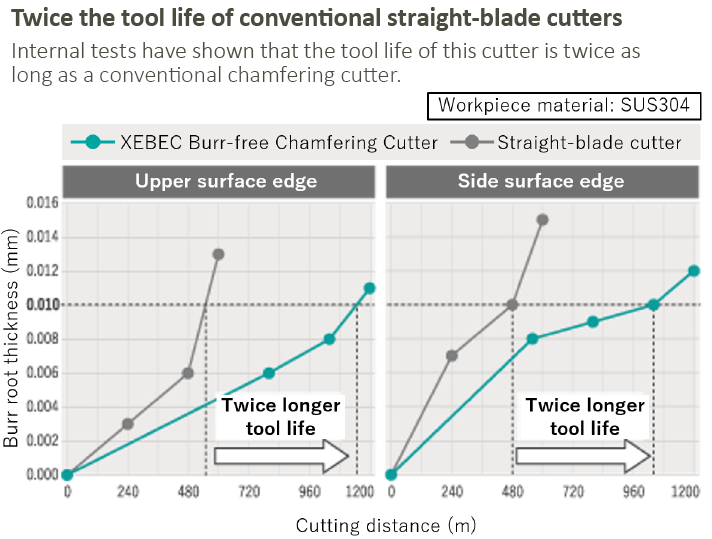

The tool also lasts twice as long as conventional straight-blade cutters, as proven by internal tests. This longer tool life is another way the chamfer cutter saves on tool costs.

It’s an incredible upgrade for manufacturers and machine shops, and our customers are really excited about it. In 2023, this tool won the prestigious Germany’s Best of Industry Award in the machining category.

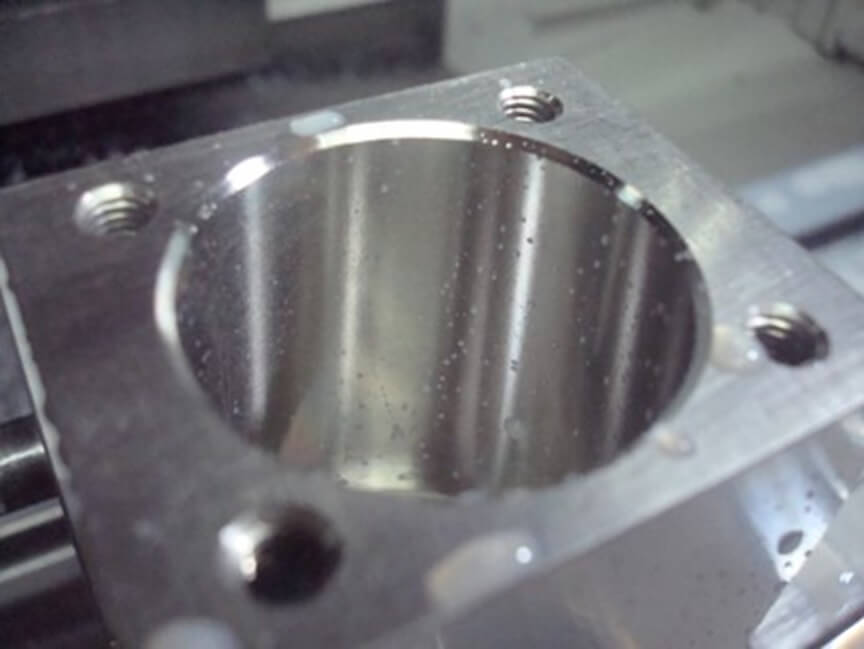

The Xebec Burrless Chamfering Cutter in action.

Successful Applications of the Xebec Burrless Chamfering Cutter

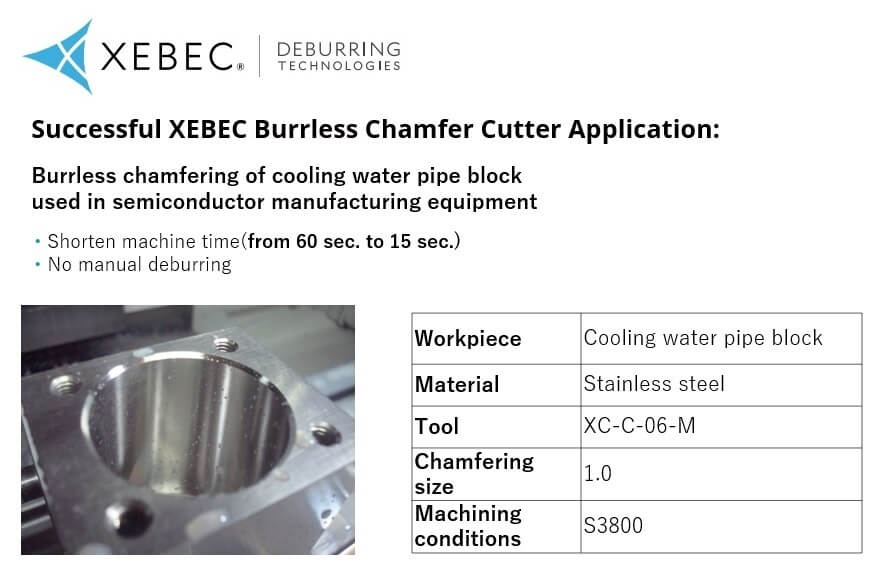

Burrless chamfering of cooling water pipe block

When a Xebec Burrless Chamfering Cutter was used in an application with a stainless steel cooling water pipe block for semiconductor manufacturing equipment, the results were:

- Shortened machine time – from 60 seconds to 15 seconds!

- Eliminated manual deburring process.

Burrless chamfering of production equipment component

When a Xebec Burrless Chamfering Cutter was used in an application with a carbon steel production equipment component, the results were:

- Eliminated 5-minute manual deburring process.

- No scratches on the surface and edges.

Do you have an application in mind for the Xebec Burrless Chamfering Cutter? Reach out to our deburring experts to discuss your process.