The powertrain industry can reduce burr formation with Xebec for better production output, quality consistency and safety….

Powertrain

Improve machine shop productivity by thread deburring with Xebec ceramic fiber brushes. Contact IPT America to learn about our thread deburring tools….

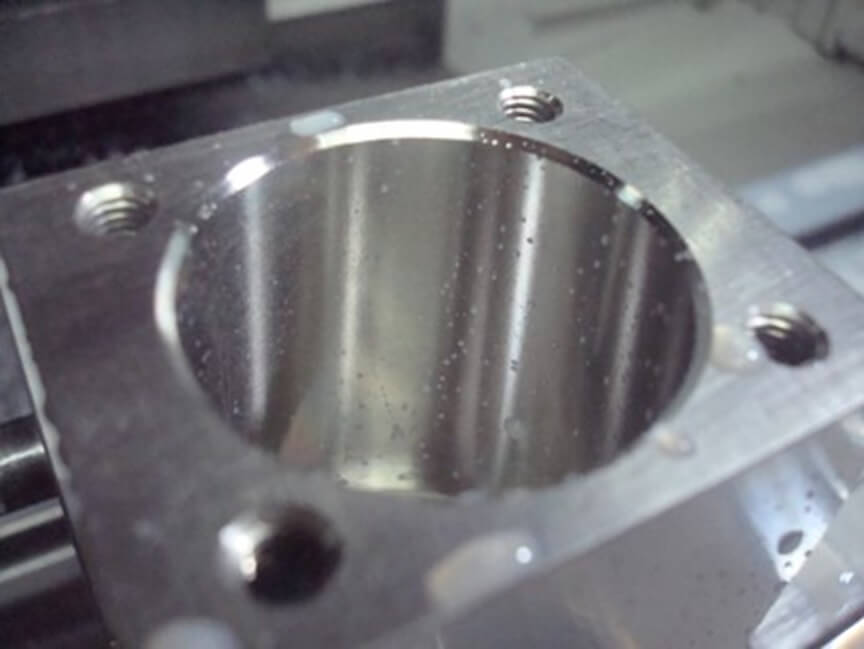

Xebec Deburring Technologies offers the best cutting tool for a chamfer edge, guaranteed to eliminate secondary burrs….

Invest in automated deburring and finishing tools by Xebec to improve metalworking safety and eliminate machine shop safety hazards….

Build resilience and liquidity with Xebec deburring tools that improve your deburring and finishing operations with increased productivity and consistent quality….

Xebec deburring tools can help meet sustainability goals and improve the quality, consistency and productivity of your deburring and finishing operations….

Knowing how to identify the type of burr produced helps in figuring out the best way to remove it. You can count on help from the deburring experts at Xebec Deburring Technologies….

Done-in-one machining isn’t a new concept. But it’s also not the most common means of production, especially for smaller operations….

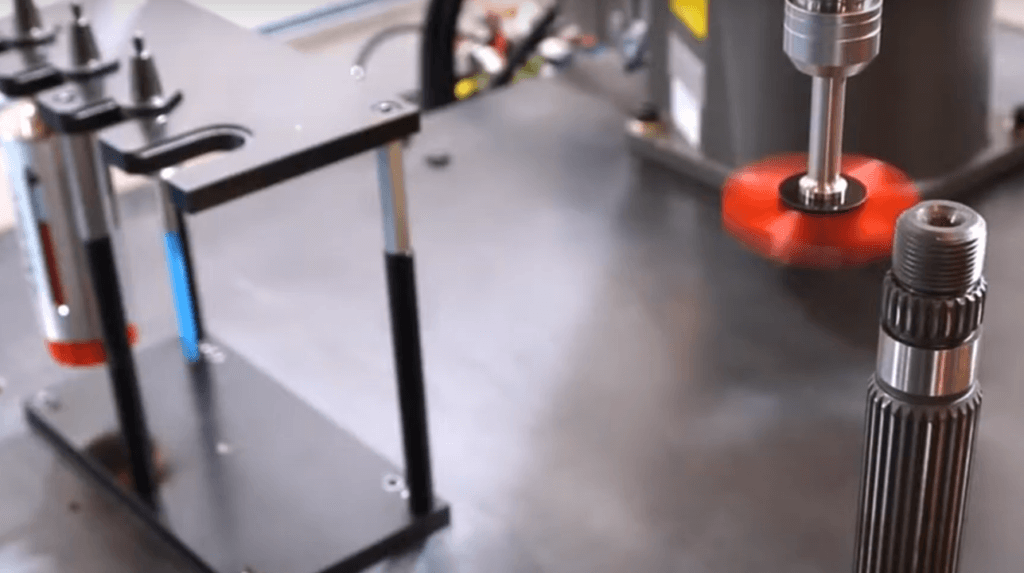

Yes, your CNC operation can actually be more productive by automating deburring inside the CNC and performing the tapping outside it. …

We’ve added another tool to our arsenal to help customers that need to deburr round parts, channeled diameters and deeper bores….

Surface finishing is an important part of the manufacturing process. It involves removing or reshaping the material to achieve a specific surface roughness that ensures post-production performance and endurance. It is often the last step before a part is…

Joining the EV and HEV automotive market? High tech industries like aerospace use Xebec Deburring solutions to meet tight tolerances and increase production….

According to the Global Powertrain Outlook 2021, the powertrain industry is seeing continued focus on features that are fuel-efficient, have a lower impact on the environment and promote safety, regardless of vehicle type….