Learning Center Blog

Manufacturers that are in or serve the energy sector can benefit greatly from capturing this demand, but it’s not as simple as just accepting and fulfilling jobs….

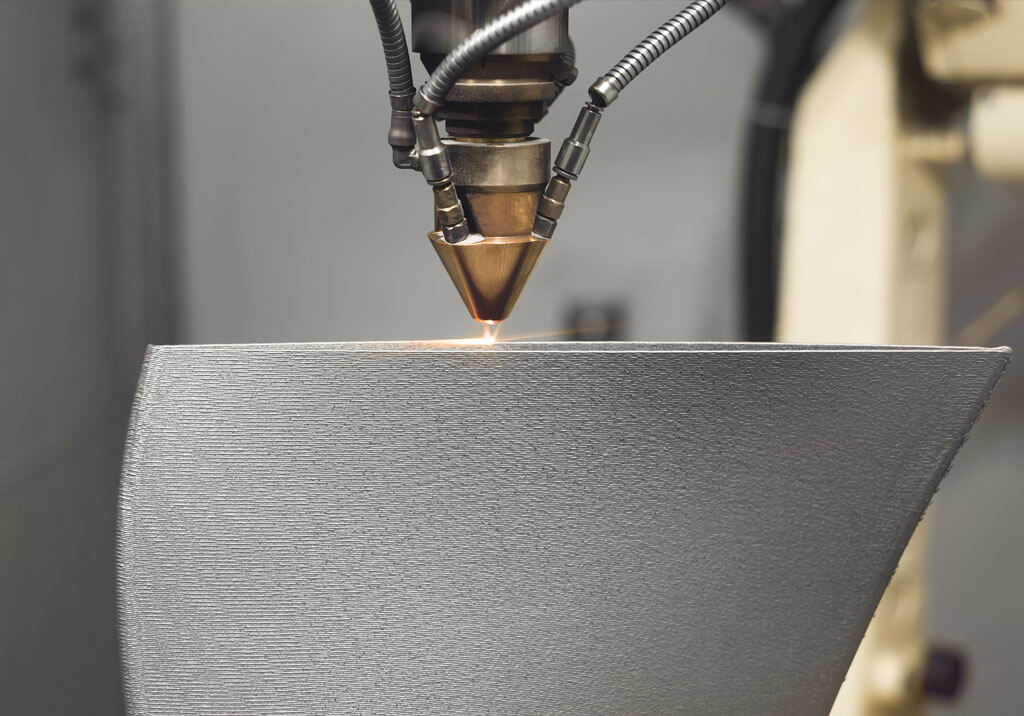

Additive manufacturing is emerging as a powerful tool in how manufacturers create parts and products in many industries, especially those that have designs that are constantly evolving and require numerous prototypes….

Any opportunity to improve processes and shorten run time can reduce unnecessary costs and improve a machine shop’s bottom line. It can also introduce opportunities for growth and lead to new business….

Manufacturers can often outsource work where they have critical gaps and can also improve inefficient processes and invest in technologies that automate tasks, improve speed and reduce inefficiencies….

Implementing Lean manufacturing helps address these types of waste: defects, over-production, waiting, non-utilized talent, transportation, inventory, motion and extra-processing….

When you consider and calculate the manual processes that take more time and resources versus their potential with automation, do you consider your deburring and finishing methods?…

Manufacturers are more actively seeking automated and/or advanced tools and technology that will help solve for these concerns – even if it’s just one tool or process at a time….

This article details how Xebec’s ceramic fiber brushes are ideal for deburring, cutter mark removal and polishing of molds following the milling process….

Manual deburring is still the primary process for many manufacturers and job shops. However, the work is laborious and subject to the skill of the operator….

Progressive machine shop owners are increasingly using technology to reduce injuries and promote safety for hard to replace staff….