Exotic metals (also known as superalloys, exotic alloys, high-performance or advanced metals) encompass a group of materials with superior strength and durability, resistance to oxidation and corrosion and deforming at high temperatures or under extreme pressure.

This makes them ideal candidates for demanding applications, such as:

- Aerospace (turbine blades, landing gear, rocket components)

- Medical devices, tools and implants

- Automotive and energy (high performance engines, nuclear reactor parts)

- Electronics and semiconductor (heat sinks, superconductors)

However, manufacturing high-performance materials such as titanium, Inconel, Hastelloy or metal-matrix composites typically result in shorter tool life, increased tooling costs, expensive downtime events, higher cycle times and surface irregularity.

That means for exotic metals, traditional deburring and finishing methods simply don’t cut it (and will cost you more in rework and scrap).

Xebec’s ceramic fiber deburring solutions can increase productivity, improve quality and reduce costs in your operation. Let’s explore why exotic materials require a modern approach.

>> Learn how Xebec Helps Aerospace Industry Manufacturers Reach New Heights

Understanding Superalloys and Exotic Materials

What’s considered an exotic material or alloy?

Exotic metals and alloys are high-performance materials with unique properties compared to conventional alloys. They are often used in manufacturing because they are stronger, more corrosion resistant, and more heat tolerant than conventional materials. Other hard materials used in machining are non-metals such as carbon fiber, glass-filled plastics or phenolics and machinable carbide.

Some common examples of exotic materials include:

Titanium: Titanium is a corrosion-resistant and strong hard metal alloy, and its biocompatibility makes it an ideal material for certain medical industry applications. It is lightweight, with a high strength-to-weight ratio. However, it can be difficult to machine.

Inconel: Inconel is primarily nickel-based with chromium and is known for its resistance to corrosion, heat and pressure. It is incredibly hard and a more difficult alloy for machining.

Tungsten: Tungsten has a higher strength-to-weight ratio than steel and is extremely durable. It is an incredibly hard metal and can be difficult to machine.

Molybdenum: Molybdenum is typically used to enhance another metal, primarily steel, to make it stronger and harder as well as more corrosion resistant. When machining molybdenum alloys, tool life is shorter because molybdenum is very abrasive and has the tendency to chip and break on the edges if the cutting tools become dull.

Some Stainless Steel: Harder and stronger than steel, stainless steel is made up of majority iron alloy and a percentage of chromium. It is also corrosion resistant. Different varieties of stainless steel will machine differently. Some are more easily machinable, where others have specific requirements in terms of cutting tools and speeds.

Cobalt Chrome: Cobalt-Chromium alloys are base-metal alloys used in biomedical applications, such as implants due to their high specific strength and biocompatibility with human tissue. Cobalt-chromium alloys and plating are used in other sectors, including gas turbine, aerospace, automotive, and electronics. Its high strength, toughness, wear resistance, and low thermal conductivity can result in rapid tool wear and short tool life of many commonly used finishing tools.

Carbon Fiber: Considered an exotic material, carbon fiber is commonly used in high-performance applications, such as aerospace, outdoor sports gear and high performance motorcycles. It has lightweight, high-strength properties and is becoming more common in various applications, although it can be difficult to machine.

>> Learn how Xebec Helps Medical Manufacturers Innovate at Pace with the Industry

Application Challenges in Deburring Exotic Metals and Alloys

How does material type impact deburring applications?

Material selection plays a significant role in decisions around deburring methods, speeds and tool selection. While exotic materials like titanium, Inconel, tungsten, ceramics, molybdenum, and Hastelloy are chosen for unique properties, those same qualities create challenges when deburring and milling.

Challenges with milling and deburring exotic materials and alloys include:

High Hardness

A material’s hardness can impact burr formation when machining. One commonly used test to determine hardness is called the Rockwell Hardness Test. If a material has a high Rockwell hardness value, it makes it more difficult to machine, cut and deburr.

>> Improving Surface Finish in Machining: Decoding Symbols and Hardness Factors

Poor Thermal Conductivity

Many exotic materials have poor thermal conductivity, causing heat to concentrate at the cutting areas. When heat is concentrated in these locations, it can degrade what workpiece’s surface finish along with the cutting tool’s integrity.

Abrasiveness

Exotic materials often have abrasive qualities, leading to rapid deterioration of the cutting tool. Shorter tool life means more tool changes, increasing operational costs and downtime.

Complex Burr Formation

Harder materials generate more aggressive burrs that are difficult to remove without damaging the component. If burrs are not removed properly, it can have a disastrous impact on the final product’s functionality and safety.

Note: Some specialized industries like aerospace and medical device manufacturers demand tight tolerances, making over-deburring a risk factor that could compromise part integrity.

Surface Finish Considerations

Since many exotic materials may have low thermal conductivity or become harder as they are machined, this can create surface defects, microcracks or other irregularities that can interfere with fitment of two mating components, affecting the functionality of the finished product.

Special Material Compositions

Since burrs in exotic metals and super alloys tend to be stiff, work-hardened and irregular, they require precision-controlled deburring rather than brute force removal.

Compounding the issue, some exotic materials may be composites or metal-matrix materials infused with other elements such as:

- Plastic reinforced with glass

- Copper infused with aluminum oxide

- Carbon fiber-reinforced plastics

- Ceramic-infused metals

These hybrid materials have varying hardness levels within the same workpiece, requiring a delicate yet effective and adaptive deburring approach.

Xebec Deburring Tools: Ideal for High Hardness Materials & Superalloys

When it comes to working with exotic metals and alloys, precision matters.

Traditional abrasives can smear and leave residue on the workpiece, and we already know any inconsistencies on that part can be catastrophic in medical or aerospace applications.

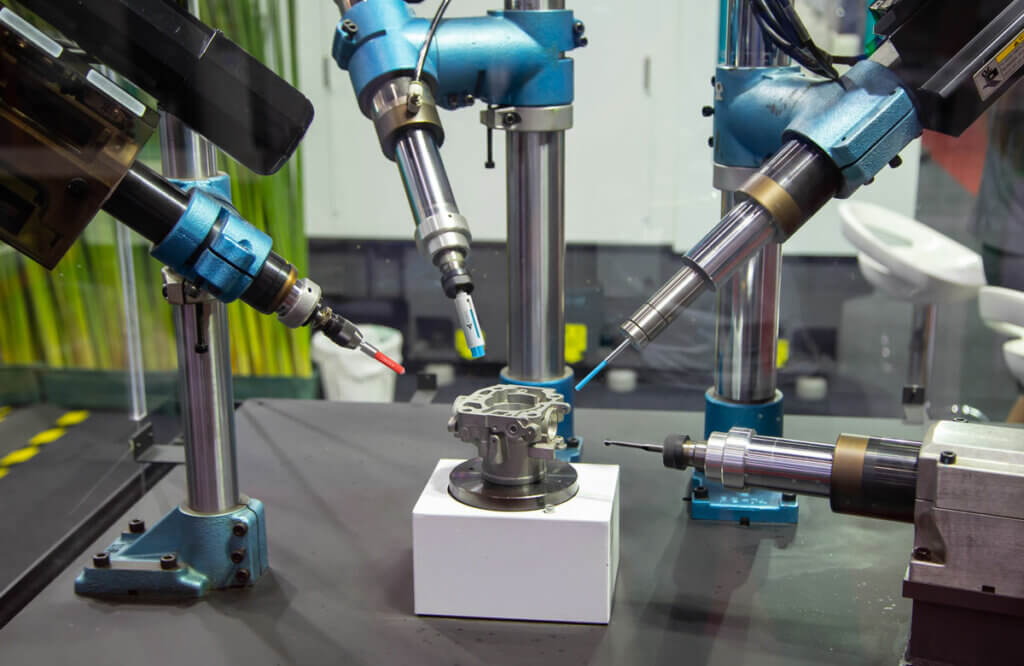

Xebec Tools are designed with advanced ceramic fiber technology that ensures consistent cutting action without damaging the base material. Unlike traditional abrasive brushes that smear or push burrs back into the material, Xebec tools shear burrs cleanly and efficiently, delivering smooth, precise results every time.

>> Why Xebec Ceramic Cutting Tools Outperform Nylon Brushes in High-Precision Machining

Xebec’s unique design combines powerful deburring with fine surface finishing—all in a single step. This not only eliminates the need for secondary finishing processes but also reduces cycle time and lowers overall tooling costs. It’s a smarter, more efficient solution for manufacturers who want top-tier performance without added complexity.

These tools excel across a wide range of materials, even up to 65 Rockwell hardness. That makes them ideal for exotic alloys where other brushes, like nylon abrasives, fall short. With Xebec, manufacturers can standardize their processes without sacrificing performance or precision.

What really sets Xebec apart is the perfect balance of power and finesse. The tools are strong enough to remove tough burrs from hardened metals, yet gentle enough to maintain tight tolerances and protect surface integrity. This dual capability improves productivity and ensures consistent, high-quality results, necessary in the aerospace, medical, firearms and energy industries.

For manufacturers with unique needs, Xebec also offers custom solutions. In fact, the secret to success is using our team’s application expertise. From specialized holders for aerospace components to stackable brush designs for varying part sizes, we’ll help you use Xebec’s turnkey options to integrate seamlessly into automated systems—ensuring accuracy, consistency, and repeatability across the board.

Where Strength Meets Finesse—Xebec Deburring Tools for Today’s Toughest Materials

The Xebec Difference

Are you struggling with a new material or want to improve an existing process? We can help you determine the best deburring and finishing solution for your manufacturing needs. Visit Xebec Deburring Technologies today or call 800-306-5901 to speak with our team.