Products

XEBEC Back Burr Cutter & Deburring Path™

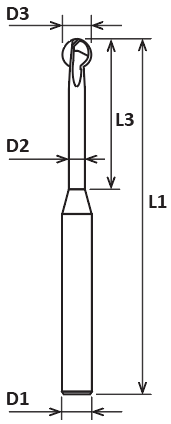

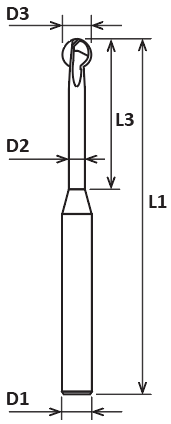

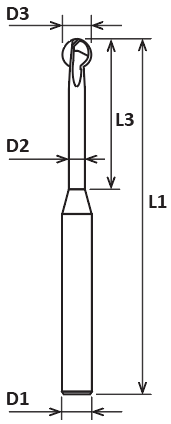

XEBEC Back Burr Cutter - Neck Down Shank

Spherical deburring Cutter with a custom-made tool Path. For CNC deburring of entry and exit holes in a single pass.

Show Tool Diameter and Length in: MM

in

EDP

D3 Cutter Diameter (mm)

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

L1 Overall Length (mm)

L3 Neck Length (mm)

Blades

Product Number

Price

51000

0.8

3

0.48

60

4.2

2

XC-08-A

$191.68

51001

1.3

3

0.78

60

6.7

2

XC-13-A

$173.01

51002

1.8

3

1.1

60

8.2

2

XC-18-A

$153.67

51003

2.8

4

1.7

70

12.2

2

XC-28-A

$165.55

51004

3.8

4

2.4

70

16.2

2

XC-38-A

$171.31

51005

4.8

6

3

70

20.2

2

XC-48-A

$183.18

51006

5.8

6

3.5

70

24.2

2

XC-58-A

$193.03

51013

2.3

3

1.4

70

12.5

2

XC-23-A

$170.27

51014

3.3

4

2

70

17.5

2

XC-33-A

$174.15

51015

7.8

8

4.7

100

40

3

XC-78-A

$317.58

51016

9.8

10

5.9

120

50

3

XC-98-A

$450.76

EDP

D3 Cutter Diameter (in)

D1 Shank Diameter (in)

D2 Neck Diameter (in)

L1 Overall Length (in)

L3 Neck Length (in)

Blades

Product Number

Price

51000

0.031

0.118

0.019

2.362

0.165

2

XC-08-A

$191.68

51001

0.051

0.118

0.031

2.362

0.264

2

XC-13-A

$173.01

51002

0.071

0.118

0.043

2.362

0.323

2

XC-18-A

$153.67

51003

0.11

0.157

0.067

2.756

0.48

2

XC-28-A

$165.55

51004

0.15

0.157

0.094

2.756

0.638

2

XC-38-A

$171.31

51005

0.189

0.236

0.118

2.756

0.795

2

XC-48-A

$183.18

51006

0.228

0.236

0.138

2.756

0.953

2

XC-58-A

$193.03

51013

0.091

0.118

0.056

2.756

0.492

2

XC-23-A

$170.27

51014

0.13

0.157

0.079

2.756

0.689

2

XC-33-A

$174.15

51015

0.307

0.315

0.185

3.937

1.575

3

XC-78-A

$317.58

51016

0.385

0.394

0.232

4.724

1.969

3

XC-98-A

$450.76

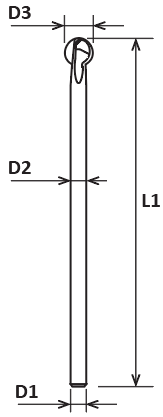

All standard Cutters have a heat-resistant AITiCrN coating. But, each Neckdown style cutter is also available in an Uncoated version which provides a sharper cutting edge that is perfect for softer, stickier materials such as aluminum or plastic.

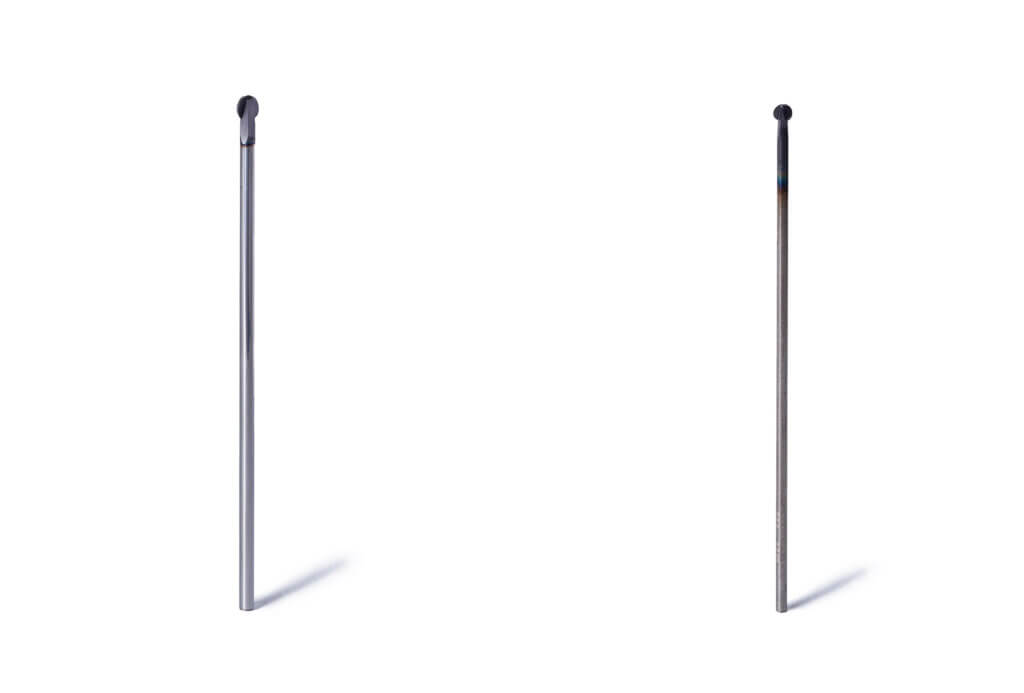

XEBEC Back Burr Cutter - Straight Shank

Show Tool Diameter and Length in: MM

in

EDP

D3 Cutter Diameter (mm)

D1 Shank Diameter (mm)

L1 Overall Length (mm)

L2 Shank Length (mm)

Blades

Product Number

Price

51007

1.8

1.1

50

48.2

2

XC-18-B

$226.29

51008

2.8

1.7

70

67.2

2

XC-28-B

$236.12

51009

0.38

2.4

85

84.62

2

XC-38-B

$245.96

51010

4.8

3

105

100.2

2

XC-48-B

$265.63

51011

5.8

3.5

120

114.2

2

XC-58-B

$285.31

51017

2.3

1.4

60

57.7

2

XC-23-B

$245.87

51018

3.3

2

80

76.7

2

XC-33-B

$256.10

51019

7.8

4.7

150

142.2

3

XC-78-B

$491.74

51020

9.8

5.9

180

170.2

3

XC-98-B

$655.65

EDP

D3 Cutter Diameter (in)

D1 Shank Diameter (in)

L1 Overall Length (in)

L2 Shank Length (in)

Blades

Product Number

Price

51007

0.071

0.043

1.969

1.898

2

XC-18-B

$226.29

51008

0.11

0.067

2.756

2.646

2

XC-28-B

$236.12

51009

0.15

0.094

3.346

3.331

2

XC-38-B

$245.96

51010

0.189

0.118

4.134

3.945

2

XC-48-B

$265.63

51011

0.228

0.138

4.724

4.496

2

XC-58-B

$285.31

51017

0.091

0.056

2.362

2.272

2

XC-23-B

$245.87

51018

0.13

0.079

3.149

3.02

2

XC-33-B

$256.10

51019

0.307

0.185

5.906

5.599

3

XC-78-B

$491.74

51020

0.385

0.232

7.087

6.701

3

XC-98-B

$655.65

XEBEC Back Burr Cutter - Uncoated

Show Tool Diameter and Length in: MM

in

EDP

D3 Cutter Diameter (mm)

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

L1 Overall Length (mm)

L3 Neck Length (mm)

Blades

Product Number

Price

51032

0.8

3

0.48

60

4.2

2

XC-08-N

$201.13

51033

1.3

3

0.78

60

6.7

2

XC-13-N

$182.27

51034

1.8

3

1.1

60

8.2

2

XC-18-N

$161.33

51035

2.3

3

1.4

70

12.5

2

XC-23-N

$171.81

51036

2.8

4

1.7

70

12.2

2

XC-28-N

$173.90

51037

3.3

4

2

70

17.5

2

XC-33-N

$176.00

51038

3.8

4

2.4

70

16.2

2

XC-38-N

$180.18

51039

4.8

6

3

70

20.2

2

XC-48-N

$192.75

51040

5.8

6

3.5

70

24.2

2

XC-58-N

$203.23

51041

7.8

8

4.7

100

40

3

XC-78-N

$320.55

51042

9.8

10

5.9

120

50

3

XC-98-N

$456.73

EDP

D3 Cutter Diameter (in)

D1 Shank Diameter (in)

D2 Neck Diameter (in)

L1 Overall Length (in)

L3 Neck Length (in)

Blades

Product Number

Price

51032

0.031

0.118

0.019

2.362

0.165

2

XC-08-N

$201.13

51033

0.051

0.118

0.031

2.362

0.264

2

XC-13-N

$182.27

51034

0.071

0.118

0.043

2.362

0.323

2

XC-18-N

$161.33

51035

0.091

0.118

0.056

2.756

0.492

2

XC-23-N

$171.81

51036

0.11

0.157

0.067

2.756

0.48

2

XC-28-N

$173.90

51037

0.13

0.157

0.079

2.756

0.689

2

XC-33-N

$176.00

51038

0.15

0.157

0.094

2.756

0.638

2

XC-38-N

$180.18

51039

0.189

0.236

0.118

2.756

0.795

2

XC-48-N

$192.75

51040

0.228

0.236

0.138

2.756

0.953

2

XC-58-N

$203.23

51041

0.307

0.315

0.185

3.937

1.575

3

XC-78-N

$320.55

51042

0.385

0.394

0.232

4.724

1.969

3

XC-98-N

$456.73

XEBEC Back Burr Cutter - 3-Bladed Short

Show Tool Diameter and Length in: MM

in

EDP

D3 Cutter Diameter (mm)

D1 Shank Diameter (mm)

D2 Neck Diameter (mm)

L1 Overall Length (mm)

L3 Neck Length (mm)

Blades

Product Number

Price

51021

0.8

3

0.48

60

3

3

XC-08-AS-3F

$245.13

51022

1.3

3

0.78

60

5

3

XC-13-AS-3F

$222.08

51023

1.8

3

1.1

60

6

3

XC-18-AS-3F

$196.94

51024

2.3

3

1.4

70

7.5

3

XC-23-AS-3F

$209.51

51025

2.8

4

1.7

70

9

3

XC-28-AS-3F

$211.61

51026

3.3

4

2

70

10.5

3

XC-33-AS-3F

$213.70

51027

3.8

4

2.4

70

12

3

XC-38-AS-3F

$219.99

51028

4.8

6

3

70

15

3

XC-48-AS-3F

$234.66

51029

5.8

6

3.5

70

18

3

XC-58-AS-3F

$247.23

51030

7.8

8

4.7

100

24

3

XC-78-AS-3F

$389.69

51031

9.8

10

5.9

120

30

3

XC-98-AS-3F

$553.10

EDP

D3 Cutter Diameter (in)

D1 Shank Diameter (in)

D2 Neck Diameter (in)

L1 Overall Length (in)

L3 Neck Length (in)

Blades

Product Number

Price

51021

0.031

0.118

0.019

2.362

0.118

3

XC-08-AS-3F

$245.13

51022

0.051

0.118

0.031

2.362

0.197

3

XC-13-AS-3F

$222.08

51023

0.071

0.118

0.043

2.362

0.236

3

XC-18-AS-3F

$196.94

51024

0.091

0.118

0.056

2.756

0.295

3

XC-23-AS-3F

$209.51

51025

0.11

0.157

0.067

2.756

0.354

3

XC-28-AS-3F

$211.61

51026

0.13

0.157

0.079

2.756

0.413

3

XC-33-AS-3F

$213.70

51027

0.15

0.157

0.094

2.756

0.472

3

XC-38-AS-3F

$219.99

51028

0.189

0.236

0.118

2.756

0.591

3

XC-48-AS-3F

$234.66

51029

0.228

0.236

0.138

2.756

0.709

3

XC-58-AS-3F

$247.23

51030

0.307

0.315

0.185

3.937

0.945

3

XC-78-AS-3F

$389.69

51031

0.385

0.394

0.232

4.724

1.181

3

XC-98-AS-3F

$553.10

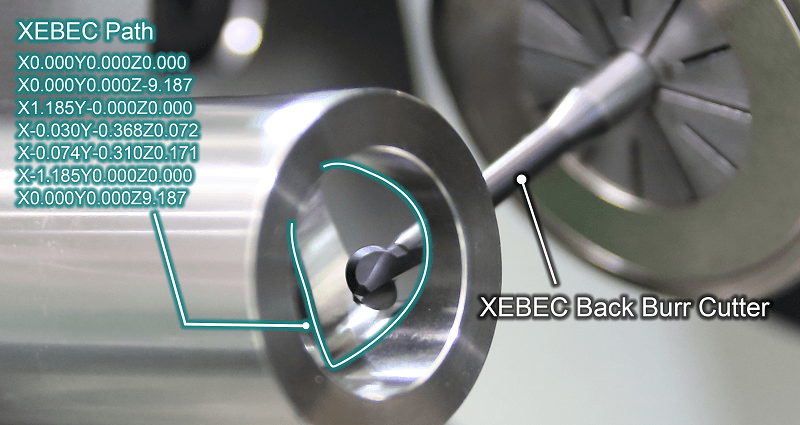

Xebec Path

Let us create the path data for your Xebec® Back Burr Cutter application. Xebec® Path data is guaranteed for burr free performance and maximum tool life. Get started now by using our fast online assessment tool.

How to Order

To Get Started Complete the Free Online Assessment for Path

You can check whether XEBEC Back Burr Cutter and Path can be implemented on your workpiece and machining equipment. The result is immediately available.

The assessment will evaluate one program for each submission. Some applications may require multiple programs.

NOTE:

Select “Combined Lathe” if the machine uses the X-Axis to control diameter.

Select “Automatic Lathe” if the machine uses the Y-Axis to control diameter.

After completing the assessment, Xebec will determine if it is a successful application and recommend a cutter type based on the information provided. After placing an order through your distributor, the Path data file will be created and sent to the customer for review and approval. Xebec guarantees the path to perform without secondary burrs.

Custom Path

We can also create custom path data for the most complex edge profiles.

Send us an email today to get started on a non-standard path:

Features of Xebec Back Burr Cutter & Path™

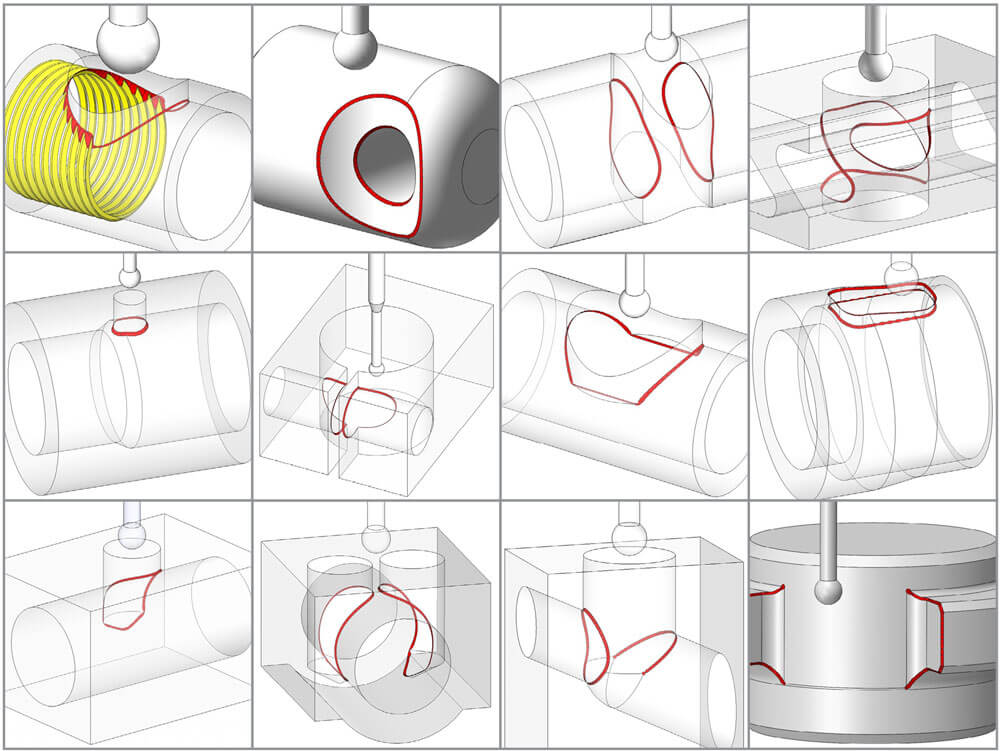

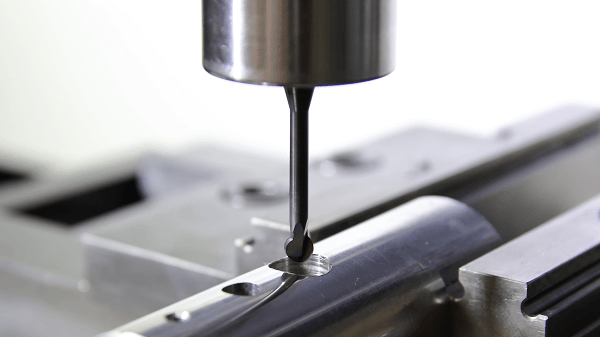

XEBEC’s innovative software enables back burring on a 3D curved surface in combination with the uniquely designed Cutter. The path data can be used as soon as being installed on a NC program, saving your time to make your own program.

Learn more about this unique solution in this article from our Learning Center Blog: The Xebec Back Burr Cutter & Path – A Consistent Path to Excellence

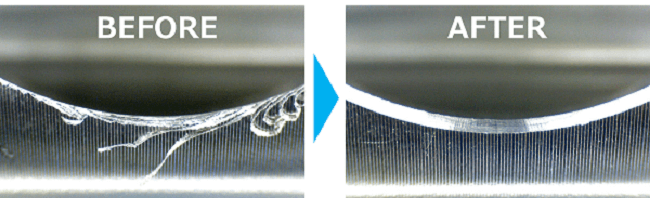

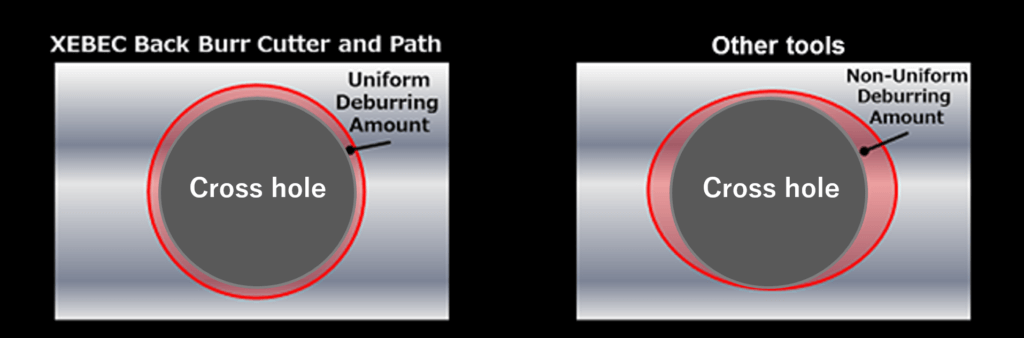

Uniform Edge Shape by Consistent Deburring Amount

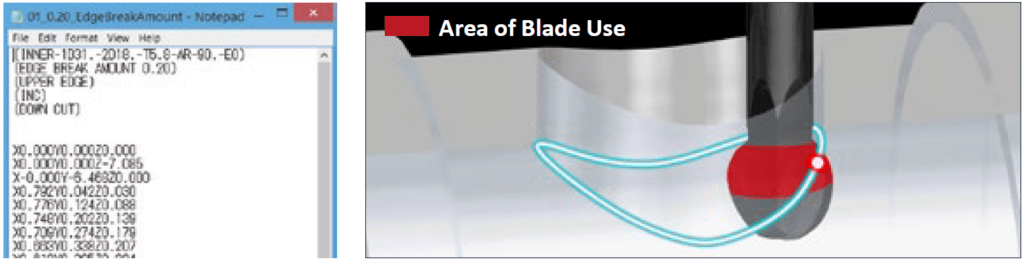

Faster Operating Time Thanks to the Unique Cutter Design

Long Tool Life by Using the Entirety of the Cutting Blade

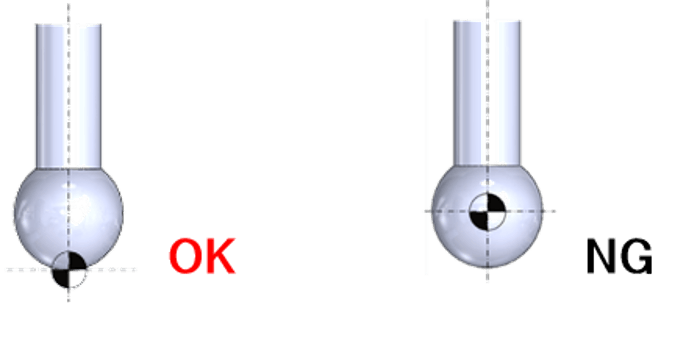

The contact points of the spherical cutting edge is continuously shifting. The red part shows the range of the blade use.

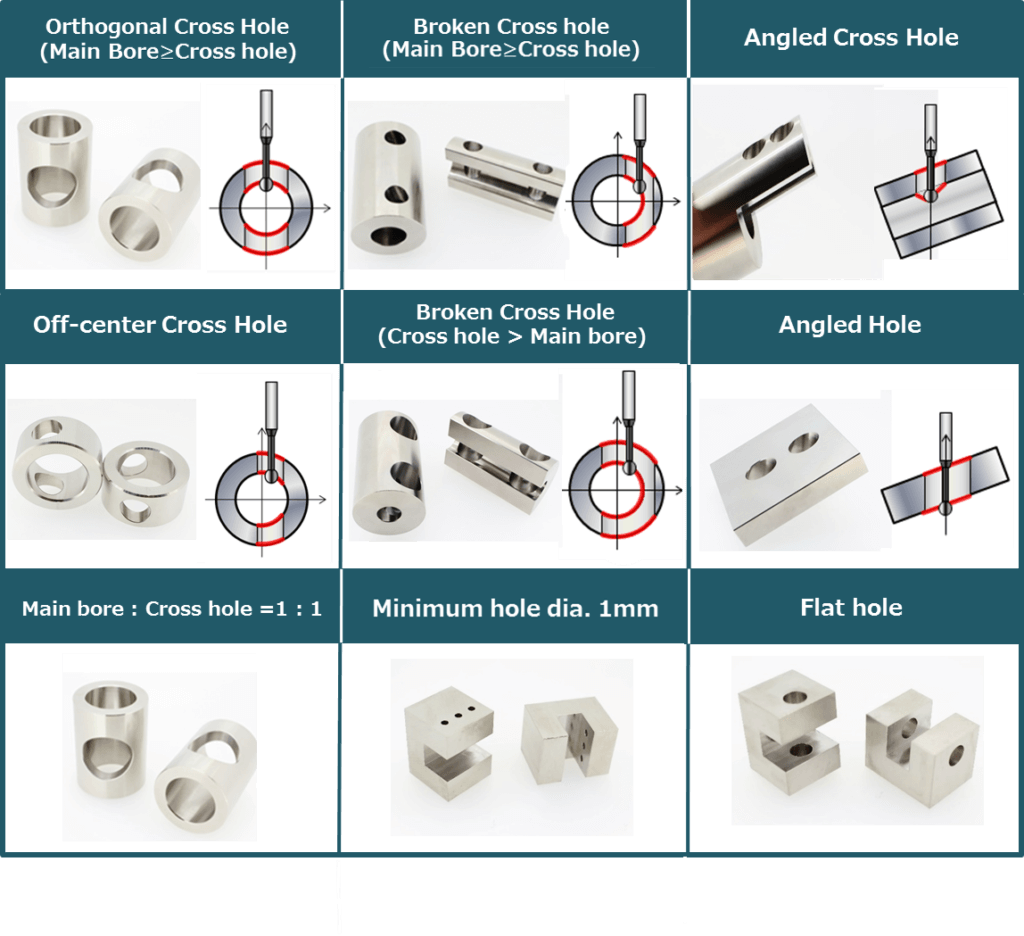

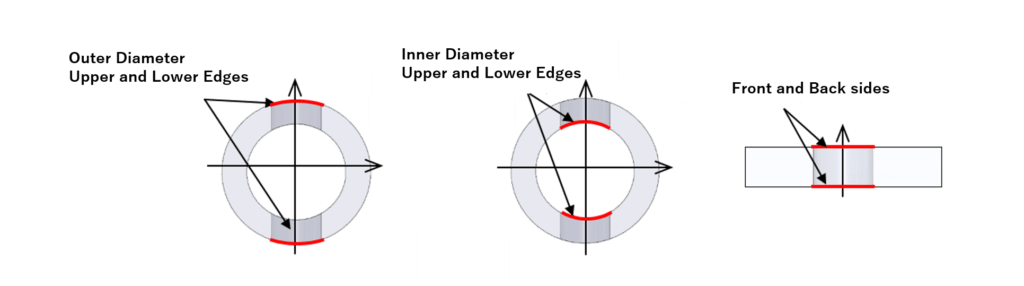

Applicable Areas

Features of Xebec Back Burr Cutte

- Micro-grain cemented carbide: Sharp and long lasting

- Highly heat-resistant AlTiCrN coating: Support materials from non-ferrous (e.g. aluminum) to difficult-to-cut materials (e.g. titanium and inconel)

- Helical Blade: Cleaner cutting edge and prevent secondary burrs

Applicable Equipment

The tool can be mounted on machining center (XYZ-axis) or combined lathe (XZY or XZC-axis). 3-axis simultaneous control is required. For combined lathe, polar coordinate interpolation is required. It cannot be used maually.

How to Use

Please refer to the instruction manual before use.

Path Setup

Please refer to the Xebec Back Burr Cutter & Path™ Setup Guide

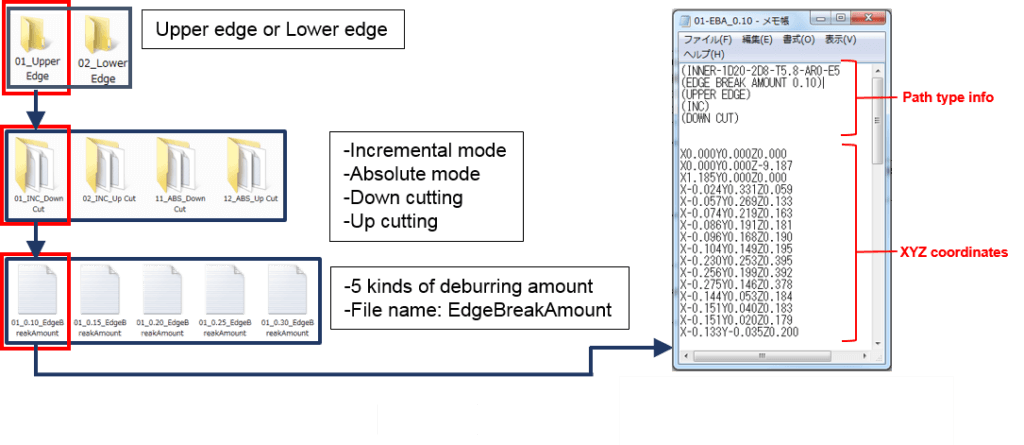

Point Group Data

The point group data is provided by the set.

Deburring Amounts and Cumulative Error

Deburring amout is a width of an edge after deburring. 5 deburring amounts are provided for each Path data. Select a deburrig amount wchich fits into processsing accuracy of a hole diameter and position.

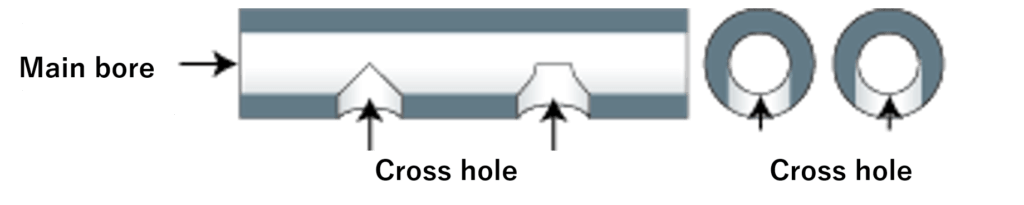

Make the cumulative errors of the positions between the main bore and cross hole, and the hole diameters as small as possible.

Product Code

Cutter Diameter (MM)

Deburring Amount (MM)

1

2

3

4

5

Allowable Cumulative Error (MM)

XC-08-A

0.8

0.02

0.04

0.06

0.8

0.1

0.03

XC-13-A

1.3

0.04

0.06

0.08

0.1

0.12

0.05

XC-18-A / B

1.8

0.07

0.09

0.11

0.13

0.15

0.08

XC-28-A / B

2.8

0.08

0.11

0.14

0.17

0.2

0.1

XC-38-A / B

3.8

0.09

0.13

0.17

0.21

0.25

0.12

XC-48-A / B

4.8

0.1

0.15

0.2

0.25

0.3

0.15

XC-58-A / B

5.8

0.1

0.15

0.2

0.25

0.3

0.18

Description of Xebec Path

For machining center use, 1 Path data consists of 40 kinds of files.

- 2 edge type (upper and lower edge)

- 4 modes (incremental and absolute mode, down and up cutting)

- 5 deburring amounts

For combined lathe use, 1 Path data consists of 20 (XZY-axis) or 10 (XZC-axis) kinds of files.

Positioning of the Tool Length Offset

The point group data of the XEBEC Path is calculated based on the tip of the Cutter. Configure the tool length offset at the tip of the Cuttter. Otherwise, it may cause breakage of the Cutter or machinery.

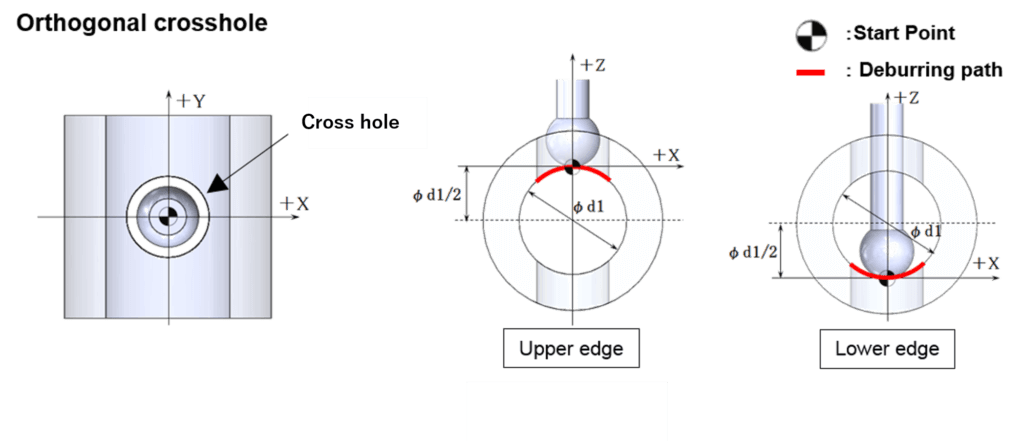

Start Point

Type B: Inner Diameter Upper & Lower Edges (Machining Center)

For the X and Y axes, set the start point to the center coordinate of the cross hole. For the Z axis, set the start point upward or down ward by the length of the radius of the main bore φ1 from the center coordinate. Prior to calling a XEBEC Back Burr Path program, make sure to position the Cutter to the start in all X,Y and Z axis. *For absolute mode paths, a start point is set as the origin of processing (X0, Y0, Z0)

Type BY: Inner diameter upper and lower edges (combined lathe XZY-axis)

If the diameter of the cross hole is equal to or greater than the diameter of the main bore. (For example, if the main bore is Φ10 mm and the cross hole is Φ10 mm or larger.)

Cross-Shaped Hole

If the diameter of the cross hole is more than 70% of the diameter of the main bore. (For example, if the main bore is Φ10 mm and the cross hole is Φ7 mm or larger.)

Process Conditions

The tool projection length is defined by cutter diameters (Dc). For example, for XC-18-B, 6Dc would be 10.8mm (6 x 1.8mm = 10.8).

Neck Down Shank Type

Product Code

Cutter Diameter (MM)

Projection Amount

Aluminum Alloy

Spindle Speed (Min-1)

Feed (mm/min)

Carbon Steel/Alloy Steel/Stainless Steel

Spindle Speed (Min-1)

Feed (mm/min)

XC-08-A

φ0.8

5Dc

20000

650

20000

600

XC-13-A

φ1.3

5Dc

20000

650

20000

600

XC-18-A

φ1.8

5Dc

20000

650

20000

600

XC-23-A

φ2.3

5Dc

18000

950

15000

750

XC-28-A

φ2.8

5Dc

15000

1400

12500

1000

XC-33-A

φ3.3

5Dc

12700

1250

10600

1050

XC-38-A

φ3.8

5Dc

11000

1600

9200

1200

XC-48-A

φ4.8

5Dc

8500

1100

7200

1100

XC-58-A

φ5.8

5Dc

7000

1600

4500

1350

XC-78-A

φ7.8

5Dc

5400

1350

4500

1350

XC-98-A

φ9.8

5Dc

4300

1300

3600

1150

Straight Shank Type

Product Code

Cutter Diameter (MM)

Projection Amount

Aluminum Alloy

Spindle Speed (Min-1)

Feed (mm/min)

Carbon Steel/Alloy Steel/Stainless Steel

Spindle Speed (Min-1)

Feed (mm/min)

XC-18-B

φ1.8

6Dc

9700

480

9700

480

XC-23-B

φ2.3

6Dc

7900

480

7900

480

XC-28-B

φ2.8

6Dc

6200

620

6200

620

XC-33-B

φ3.3

6Dc

5400

460

5400

460

XC-38-B

φ3.8

6Dc

4600

460

4600

460

XC-48-B

φ4.8

6Dc

3600

360

3600

360

XC-58-B

φ5.8

6Dc

3000

300

3000

300

XC-78-B

φ7.8

6Dc

1600

240

1600

240

XC-98-B

φ9.8

6Dc

1300

200

1300

200

1. When processing alumnium alloy, you can increase the spindle speed about twice the speed listed on the table above.

2. In order to improve processing result, change the spindle speed, table feed or deburring amount.

3. If the spindle speed and /or table feed fail to meet the standard conditions listed in the table, or an abnormal vibration or noise occurs, lower the spindle speed and table feed at an equel rate. Make sure to maintain the feed per rev (fn).

There are three reasons for long tool life of the Cutter; (1)it can maintain minimum cutting amount, (2)the contact point of the spherical cutting edge is continuously shifting, and (3)the Cutter is specially designed for deburring with high-quality material and coating.

The tool life depends on stiffness of workpiece or jig, machining accuracy, and burr size. According to the internal test, the Cutter lasts couple times longer than general carbide end mill.

No, we do not deal with cutting service.

No, it is not possible. If you re-grind the Cutter, the Cutter shape will be changed. Then the Cutter would not contact to the hole edge. We do not deal with re-grinding request.

Not only non-ferrous metal such as aluminum alloy, but also difficult-to-cut materials such as stainless steel or alloy steel can be processed.

According to our internal test, the Cutter could process aluminum alloy without creating build-up edge.

We haven’t performed any test with high hardness material.

Yes, but it depends on hardness of the burr.

If burr root thickness is smaller than the deburring amount, burrs can be removed by the Cutter. We prepare 5 kinds of deburring amount for each cutter diameter. Please refer to How to Use page for details.

We have no specified coolant. You can use coolant for other cutting tools (drilling, end mill etc.)

As same as other cutters, tool life will be extremely shortened for intermittent cutting.

Yes, you can purchase the Cutter from 1 unit.

The Cutter can be used with both flat surface holes and cross-holes, so you can combine each Path.

This is the cutting process, so that secondary burrs can occur in a precise way. However, the Cutter has excellent cutting ability, so that any secondary burrs will mostly not occur, unless the Cutter has been used heavily over time.

Deburring amount will vary and depends on the positioning gap of the workpiece, or runout of the Cutter. In theory, allowance of deburring amount is within 0.05mm.

Yes, you can buy only the Cutter. But we recommend you to use the Cutter and the Path together, because it will lead maximum effect for cutting quality and tool life.

If your machine doesn’t satisfy the recommended spindle speed, lower the spindle speed and table feed at an equal rate.

No. There is no expiration date.

No, it is prohibited to use any other kinds of tool besides the XEBEC Cutter, when using the XEBEC Path.

The deburring amount achieved with the Xebec Cutter and Path is one of a kind. But, in the case of a path by trigonometric function, the difference of deburring amount will be up to a few millimeters depending on combination of hole size. In the case of a path by CAD/CAM, it will take a long time to output path data.

No, you should not use the Cutter on a casting surface because of poor dimensional precision. It may leave burrs remaining or break the tool.

It depends on the level of dimensional precision, but it may leave burrs remaining or break the tool.

The path is typically delivered by CD. However, if you cannot use CD in relation with your drive, we will assist you to deliver by another digital method that fits your system.

Yes, it is possible to adjust coordinates. Make sure to use the incremental path and adjust the start point.

The Cutter and Path requires high-speed and high-accurate machining. It is recommended to use advanced preview control function.

Standard size is less than 5KB.

In case of cross hole with main bore dia.φ20mm and cross hole dia.Φ10mm, the number of program block will be approx. 80 lines, and program capacity is about 2KB. The number of program blocks can be twice that, depending on size combination between primary bore and cross-hole.

It is “.txt” format. You can edit the file by general document software on your PC.

The Path data contains coordinates data (e.g. X, Y, Z coordinates)only. Please add O number, G code, or M code by yourself. In addition, please note that feeding speed command (F code) is not included in our program.

No, it is not possible.