In an industry driven by tolerances measured in thousandths of an inch, it’s easy to assume that when a part comes off the CNC machine to spec, the work is done. The surface is pristine, the dimensions are precise,…

General

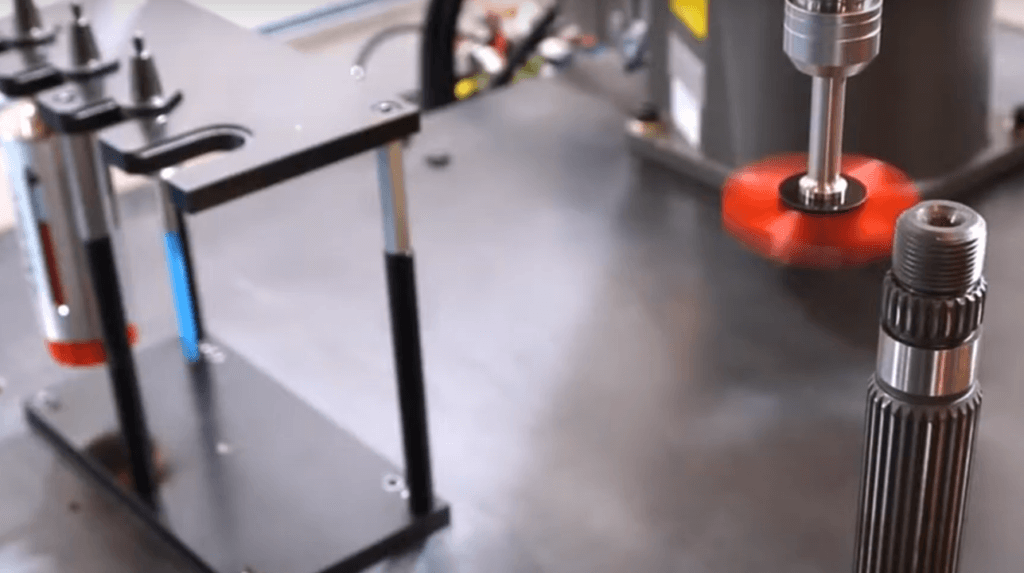

Creating the Ideal Edge Break with Xebec Tools in CNC Machining When designing or refining a CNC machining process for a new part, machine process engineers and application development teams must give deliberate attention to edge breaking. The right…

There are many ways to increase efficiency and reduce downtime. The best solution for you will depend on the available resources and your needs. Deburring is a critical process in CNC machining, ensuring that parts are free…

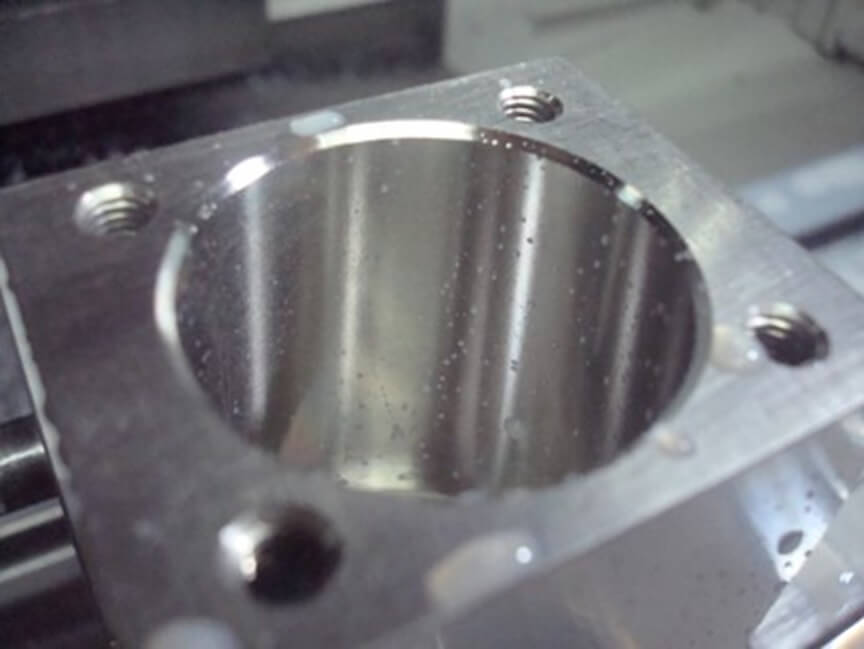

Modern methods for cross hole deburring resulting in improved efficiency and reliability….

Xebec deburring tools help manufacturers maintain strict clean room requirements and quality standards for industries like medical, aerospace, and semiconductors….

Learn about surface finish symbols and methods to improve texture, smoothness, and integrity of machined parts. Explore how Xebec ceramic tools deliver precision and consistency….

Discover how surface roughness affects performance and compliance. Achieve flawless finishes with XEBEC tools designed for precise surface treatment….

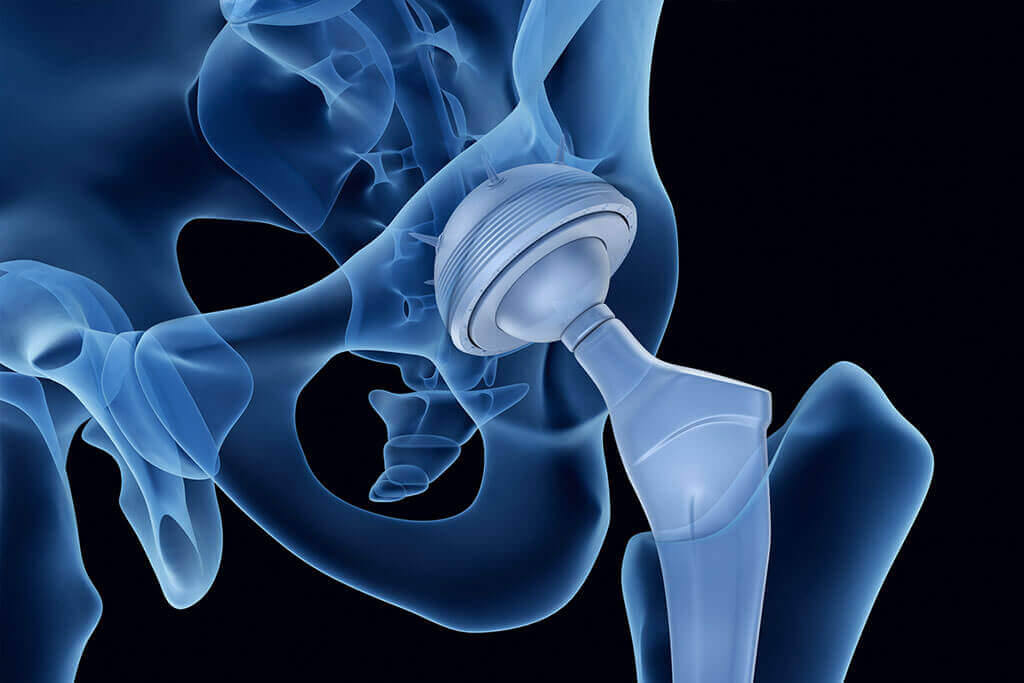

Along with expectations for high performance, medical facilities require exceptional quality and durability, especially for Class III and Class IV devices which are used to support or sustain human life or those that present a potentially high risk for…

Improve machine shop productivity by thread deburring with Xebec ceramic fiber brushes. Contact IPT America to learn about our thread deburring tools….

Xebec Deburring Technologies offers the best cutting tool for a chamfer edge, guaranteed to eliminate secondary burrs….

Invest in automated deburring and finishing tools by Xebec to improve metalworking safety and eliminate machine shop safety hazards….

Build resilience and liquidity with Xebec deburring tools that improve your deburring and finishing operations with increased productivity and consistent quality….

Xebec deburring tools can help meet sustainability goals and improve the quality, consistency and productivity of your deburring and finishing operations….

Knowing how to identify the type of burr produced helps in figuring out the best way to remove it. You can count on help from the deburring experts at Xebec Deburring Technologies….

Done-in-one machining isn’t a new concept. But it’s also not the most common means of production, especially for smaller operations….

Yes, your CNC operation can actually be more productive by automating deburring inside the CNC and performing the tapping outside it. …

We’ve added another tool to our arsenal to help customers that need to deburr round parts, channeled diameters and deeper bores….

Xebec Deburring Technologies is the best solution for removing burrs and obtaining quality finishes for manufacturers in the medical device industry. For more info contact us at (800) 434-9775….