Energy consumption is steadily rising, and demand is strong for both traditional and renewable resources. And that demand isn’t poised to cease, as energy and electrical power remain ever pivotal in running our modern world and economy. Manufacturers that are in or serve the energy sector can benefit greatly from capturing this demand, but it’s not as simple as just accepting and fulfilling jobs.

Manufacturers must have the equipment, infrastructure and technology in place to produce quality parts in a timely fashion. In a world reliant on such resources, and in an industry with rising standards for part precision, fit and quality, it’s imperative for these manufacturers to get it right. And operationally, they must ensure optimal use of their resources – their people, equipment and budget. And they must produce competitively, which looks different today than it did a decade ago. Outdated processes, such as manual deburring and finishing, hinder these goals.

Today’s engineers are innovating manufacturing methods that raise the standards for efficiency and production. These innovations enable manufacturers to do more with less, empowering them to meet and accept increased demand without necessarily expanding their workforce. These capabilities and technologies take investment, but they position manufacturers for ongoing and future success, allowing them to scale more easily to meet increasing demand.

For example, if you were to automate your outdated manual deburring and finishing processes with Xebec Deburring Technologies, you could realize significant productivity gains due to the efficiency of automation and the opportunity to reallocate labor elsewhere in the production process. You’ll also realize reduced costs from scrap and rework, and you’ll have higher-quality outcomes.

The State of the Energy Industry

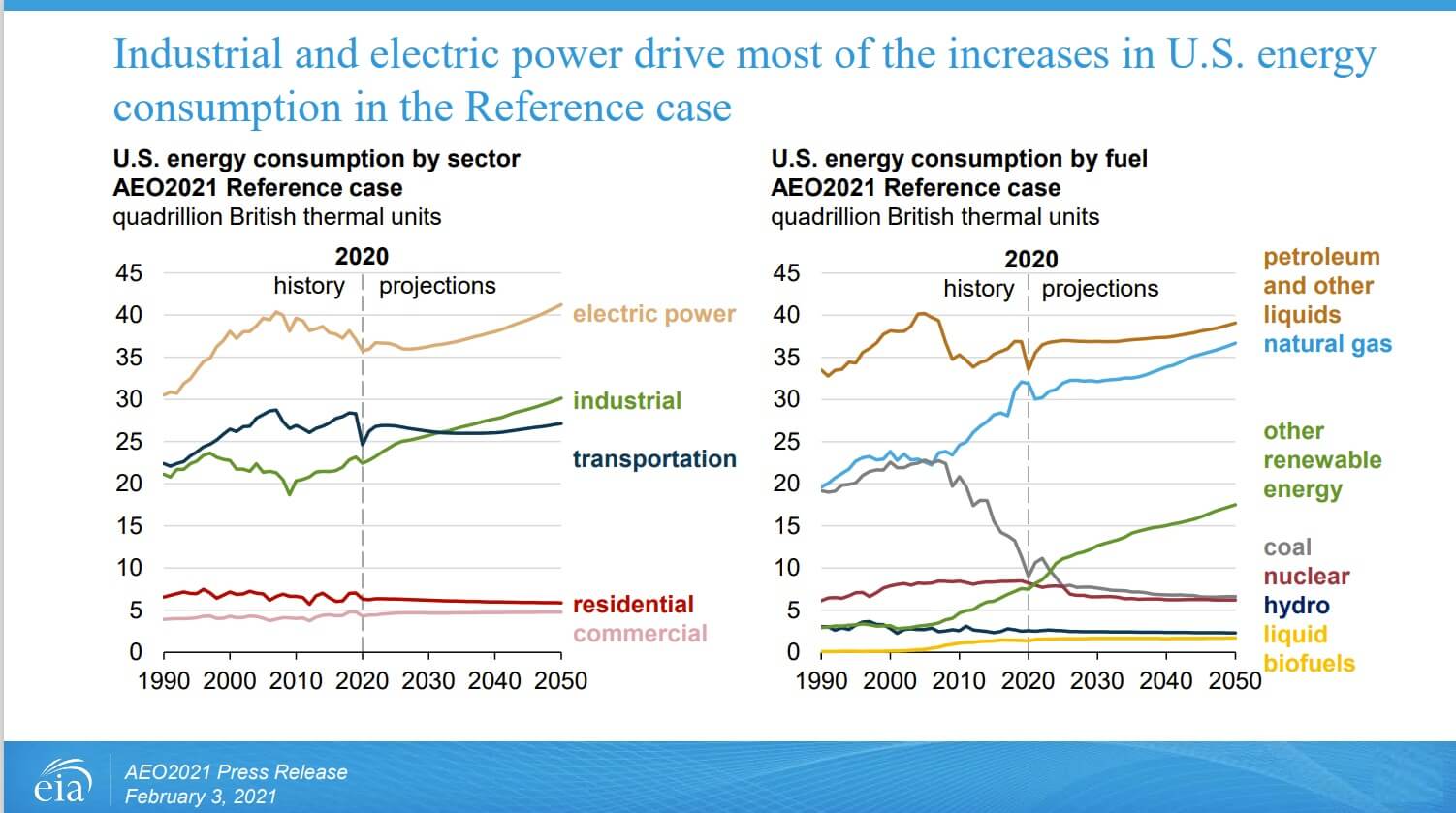

According to the US Energy Information Administra- tion Annual Energy Outlook for 2021:

- The top two drivers for energy consumption in the S. through 2050 will be industrial and elec- tric power.

- Coal and nuclear power are expected to decrease in capacity.

- The United States’ bountiful domestic ener- gy production continues to fuel its capacity to remain a global supplier for both crude oil and natural gas.

- Incentives and decreasing technology costs for renewable energy will make it a significant con- tender with natural gas, and renewable electric- ity generation is expected to increase at a faster rate than demand for electricity through 2050.

Xebec Deburring Solution Applications in the Energy Industry

Manufacturers serving the energy industry can use Xebec products to deburr, finish and polish a variety of components that go into solar, wind, oil and natural gas systems. That includes practically any metal as well as some polymers and composites that go into the assembly of final products like solar panels, wind turbines, oil drilling rigs, frameworks, motorized and electrical components.

Examples:

- Blades

- Clamps

- Flanges

- Frames

- Gear boxes

- Housings

- Mounting rails and brackets

- Piping

- Rotors

- Shafts

- Turbine towers

Wind Applications

Demand for wind energy is also expected to increase in the coming years. The Global Wind Turbine Components Market Research Report for 2021 forecasts the market will grow by nearly $28 billion from 2021 to 2025.

Metal components that go into a wind turbine, such as the tower, low- and high-speed shafts, gear box, housing, blades and rotor, can be deburred and finished to quality standards with Xebec deburring solutions. Xebec products can achieve the tight tolerances necessary in this industry, on parts ranging from the motor to the wing and the propeller.

Fluid Power Applications

According to the National Fluid Power Association’s 2021 Industry Brief, the manufacture of fluid power components in the United States in 2020 was an over $18 billion industry. Fluid power industry manufacturers serve oil and gas, water, transportation, and energy and efficiency systems. Xebec deburring solutions can be used to deburr, finish and even recondition metal components that go into fluid power systems, such as motors, pumps or compressors. Parts include housings, pipes, engine blocks, manifolds, impellers, piston rings, cylinders, valves, gears and more.

Oil and Gas Applications

According to Deloitte’s 2021 Oil and Gas Industry Outlook, demand for oil fell and then began a rapid recovery during the pandemic. Yet, as it recovers, it isn’t expected to return to pre-pandemic demand.

“This downturn is the ‘great compression’ of the O&G industry,” according to the outlook, which declares 2021 a definitive time that will prove out pioneers versus followers.

It’s important for players in this industry to keep tight control of costs, avoid liability and reputation concerns, and be prepared to compete for demand and held to strict standards. Xebec deburring solutions can be used on everything from aluminum and stainless to forged steel. For example, manufacturers trust them for deburring and finishing flanges used in pipe fittings, which must have a smooth surface and a good “seat” to avoid leakage of oil, gas or steam. Xebec products can also be used to recondition long pipes with collars and connectors for shops that service the oil and gas industry.

Solar Applications

Demand for solar energy was not significantly affected by the pandemic. And the global solar energy installed capacity is expected to more than double by 2026. Xebec deburring solutions can be used on components that go into solar panels, including frames, clamps, piping, mounting rails and brackets. For these parts, the finish is incredibly important. The frames must be smooth, with no rough edges that would otherwise damage the panels.

Small Burr, Big Problems

Flanges are a pivotal component in the oil and gas industry, connecting and securing pipes for a range of fuel and product types across a range of distances. A single poorly deburred flange that doesn’t allow for a proper, snug seal and results in a leak or failure can have devastating consequences for the company, its employees and the environment. The cost can be in the millions for a company that experiences oil spills and leakage.

For example, in 2016, Enbridge Energy Limited Partnership and related companies reached a $177 million settlement with the Department of Justice and the U.S. Environmental Protection Agency over oil spills that occurred in 2010 in Michigan and Illinois. The company agreed to put over $110 million toward prevention and operational improvements to their pipeline system.

In 2019, Sunoco Pipeline L.P. agreed to pay more than $5.4 million due to their oil spills in Texas, Louisiana and Oklahoma from 2013 to 2015. A portion of that amount is designated for corrective measures that resolve violations to environmental laws and the Clean Water Act.

Xebec Deburring Solution Applications in the Energy Industry

Xebec deburring technologies can play a role in helping energy industry manufacturers rise to new efficiency standards, so they can capture demand, control costs and scale more readily. These tools are innovative. They automate manual processes that are otherwise inconsistent and inefficient.

And Xebec ceramic fiber works like a cutting tool. It’s a durable material with a longer life than its nylon or wire counterparts, and it accomplishes each job with greater efficiency and speed. At the end of each run, you’ll have met tight specifications for finish and tolerance.

- Quality you can count on – for your reputation and your customers’.

- Fast, reliable cycle times that make way for increased production.

- Reduced resource waste, so you can reallocate staff and labor costs to higher-value activities.

- Less scrap and rework, so production stays on track and your scrap costs stay low.

- Lower chance of injury during deburring and finishing processes, particularly if automated in a machine or with a robot.