Burrs form on a variety of different materials when they are cut or machined, including and beyond metals. As a manufacturer, you want to be able to tackle opportunities with new materials in your production. Various composites and plastics are increasing in popularity, and you want to be confident about working with them.

What does deburring mean?

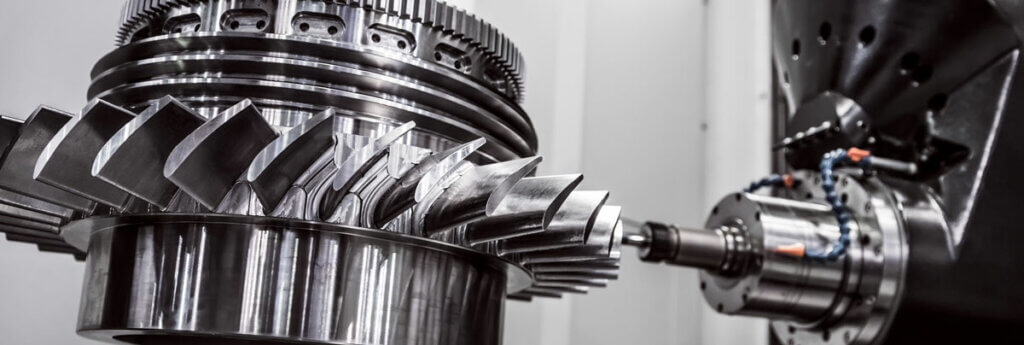

In the machining world, deburring is a secondary process used to eliminate raised edges and material fragments, known as burrs, from the component after the initial machining process, such as drilling or milling. The deburring process removes the unwanted material that is formed when the cutting tool creates stress on the material, causing it to displace rather than shear off cleanly.

This can be done a number of ways such as manual deburring, tumbling, grinding, freezing, chemical deburring, electrolysis, water jet, or using Xebec’s automated ceramic fiber brushes that acts like a cutting tool for consistently reliable results.

Knowing the best way to deburr a material involves understanding how different materials behave in the deburring process and which tools will best achieve the precision and quality you need.

For instance, Xebec deburring tools produce excellent results in a variety of applications with a broad range of workpiece materials – from PEEK plastic and aluminum to titanium and Inconel. Even with incredibly hard materials, a Xebec brush with the right programming can make the job effortless.

Machinists may also add a chamfer to a part, which is a 45-degree cut made on the sharp edge of a workpiece. A chamfered edge is often used to create clearance for joining or connecting parts. Chamfering also removes sharp edges, significantly reducing incidents of cuts and injuries to operators handling the metal piece. However, this can also generate burrs unless you use Xebec’s Burrless Chamfer Cutter, which has a patented blade type that prevents burrs during the chamfering process.

Here, we’ll outline common materials that require deburring, how they might handle differently, and how to determine if Xebec products are the best fit for your processes.

>> Burr Basics: Identifying Burr Types to Efficiently Remove

What types of materials need to be deburred?

Most materials generate burrs during production, whether from milling, drilling, cutting or otherwise. These burrs must be removed to ensure the highest quality and proper function of the resultant part or product. If they aren’t removed, there are risks down the line, including:

- Issues with assembly

- Inadequate or unsafe performance

- Loose burrs that break off during operation or use

- Risk of injury to operators

Such risks can have detrimental – if not catastrophic – consequences at any point in a part’s lifecycle, such as with knee replacements in the medical industry or flanges in the oil and gas industry.

You’ll likely recognize several of the burr-generating materials defined below, but you may not have worked with all of them. Each has its own characteristics and Rockwell C Hardness scale (HRC), which is based on the indentation hardness of a material, that make it ideal for specific parts and industries. These same characteristics also affect deburring.

Deburring aluminum and aluminum alloys:

Aluminum and alloys of aluminum are lightweight, corrosion-resistant and durable. Aluminum alloys are second only to steels in use as structural metals and they machine well. However, they aren’t very resistant to high temperatures.

Deburring brass:

Brass is relatively soft metal and is an alloy of copper and zinc. It has a low melting point, durability, electrical and thermal conductivity and high workability with hand tools and turning and milling machines. Since the metal is soft, it is easy during milling to create large burrs and gouge or scratch the surface during finishing. Special care is needed in fixturing.

Deburring carbon fiber-reinforced polymers:

carbon fiber-reinforced polymers and plastics (CFRPs) are generally known carbon fiber or carbon composite. Carbon fiber is known for being lightweight with high strength – many times stronger than steel and ideal for industries like aerospace, automotive and sports equipment. Machining carbon fiber is considered among the most challenging and requires careful tool and method selection. Generic deburring brushes aren’t capable of finishing carbon fiber. Typical cutting tools wear rapidly, resulting in damage to the surface integrity of the parts. Xebec cutting tools are specifically engineered to remove burrs and prevent delamination of drilled CFRP holes.

Ceramic deburring:

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant nonmetallic materials. Ceramic is very hard, so deburring and finishing requires strong, long-lasting tools that can withstand the process and its brittleness can lead to more burrs during the milling process.

Cobalt chrome deburring:

Cobalt-chrome, also known as cobalt-chromium, has a high specific strength and is considered difficult to cut and machine. It is commonly used for medical implants due to its biocompatibility.

Copper deburring:

Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. This high conductivity allows power systems that utilize copper to generate and transmit energy with high efficiency and minimum environmental impacts. Since it is a soft, malleable metal, special care is needed in fixturing during the milling process.

Chromium-Molybdenum deburring:

Chromium-Molybdenum is known for its exceptional high-temperature and creep-resistant properties and is ideal for high-temperature environments. Creep-resistant metals are materials designed to withstand the gradual deformation that may occur with constant stress and elevated temperatures over extended period.

Deburring exotic metals:

Also referred to as high-performance or advanced metals, these materials are different than conventional alloys. They are often ideal for demanding applications due to their superior strength, corrosion resistance and thermal stability. These metals may include the following types: various grades of stainless steel, titanium, Inconel, Chromium-Molybdenum (CrMo), or tantalum (see individual descriptions).

Deburring Hastelloy:

Hastelloy is a brand of nickel-based corrosion-resistant alloys. These alloys are made corrosion-resistant either with a blend of nickel and chromium or nickel, chromium and molybdenum. They aren’t as challenging to machine as some materials, but following specific guidelines for tool, speed and feed will ensure the best outcomes.

Deburring Inconel:

Inconel is primarily nickel-based with chromium and is known for its resistance to corrosion, heat and pressure. It is incredibly hard and a more difficult alloy for machining.

Deburring molybdenum alloys:

Molybdenum is typically used to enhance another metal, primarily steel, to make it stronger and harder as well as more corrosion resistant. When machining molybdenum alloys, tool life is shorter because molybdenum is very abrasive and has the tendency to chip and break on the edges if the cutting tools become dull.

Deburring nickel-Iron Alloys:

Nickel-Iron alloys are ideal for situations where high dimensional stability is required, such as in the aerospace industry, and will be important in the future of composite manufacturing. The hardness of Nickel-based alloys can cause cutting tools to dull quickly. The resulting burrs from the milling process are difficult to remove once they work-harden. To solve deburring challenges, some aerospace manufacturers are automating their cutting and finishing processes.

Deburring nylon:

Nylon is a generic term for a group of tough, lightweight, and elastic synthetic polymers often used in the manufacture of compression molded or machined parts. Residual burrs and flash can be generated in the molding or machining process. Flash is excess material that leaks from the mold and solidifies on the surface of the molded component. Removing parts from a mold with an ejector can leave scratch or drag marks on the surface, which is not acceptable for parts used in the medical or aerospace industries. Also, when deburring of nylon or other plastics is done by hand, it is not unusual to see more burrs created.

Deburring PEEK plastic:

PEEK is a plastic that performs superbly for various industries, including medical and aerospace industries. It has high strength and stability. It is resistant to chemicals, high temperatures and water. PEEK polymers are softer than most metals and stiffer than most plastics, so fixturing when machining is crucial. They are also abrasive on tooling, especially if reinforced with carbon fiber and glass, so high quality cutting tools are a necessity.

Deburring thermoplastic:

Thermoplastics soften to a liquid in high heat and then harden again when cooled and can be molded into a variety of shapes and structures in the injection molding process. Resins typically offer ease of machining and tight tolerances because of its inherent strength, toughness and dimensional stability. The machining process isn’t too different from machining metals, except that fixturing is very important as thermoplastic resins will deform if held too tightly.

Deburring stainless steel:

Harder and stronger than steel, stainless steel is made up of majority iron alloy and a percentage of chromium. It is also corrosion resistant. Different varieties of stainless steel will machine differently. Some are more easily machinable, where others have specific requirements in terms of cutting tools and speeds.

Deburring steel:

A common hard metal used in manufacturing, steel is strong and versatile and comprised primarily of iron with a small percentage of carbon. The amount of carbon in the steel determines the hardness of each steel grade and greatly affects its machinability. Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. High carbon steels are difficult to machine because they are tough and they may contain carbides, which abrade the cutting tool. Low carbon steels are soft, “gummy” and stick to the cutting tool, resulting in a built-up edge that shortens tool life.

Deburring titanium matrix composites (TMCs):

TMCs are heat-resistant alloys of titanium that are strong and durable. They are lightweight compared to other alternatives, such as steel or nickel-based materials, making them great options in aerospace applications. Titanium carbide (TiC) nanoparticles in TMCs make them difficult to machine and typically cost up to 10 times more than machining of aluminum alloys. That’s why using high quality deburring tools that provide consistent results is critical to save money when machining TMCs.

Deburring titanium:

Titanium is a corrosion-resistant and strong hard metal alloy, and its biocompatibility makes it an ideal material for certain medical industry applications. It is lightweight, with a high strength-to-weight ratio. However, it can be difficult to machine.

Deburring tungsten:

Tungsten has a higher strength-to-weight ratio than steel and is extremely durable. It is an incredibly hard metal and can be difficult to machine. It’s important to choose a fitting cutting tool.

How does material type affect deburring?

The composition and characteristics of a material greatly affect how easy it is to machine and deburr. As such, material type is a significant factor in decisions around deburring methods, speeds and tools.

Hardness and ductility affect the deburring process

The hardness and ductility of the material can affect how large and unruly the resultant burrs are, what speeds and feeds are necessary, how the material behaves during production, and which deburring tools will be most effective.

Xebec ceramic fiber brushes work well on hard materials because they perform like cutting tools, but they are also ideal for softer materials when selected and programmed accordingly. Aluminum, for instance, is a softer metal that tends to stick to the edges of conventional cutting tools. With Xebec deburring and finishing solutions, manufacturers can avoid this issue.

Some materials behave with a “gumminess” during production, such as stainless steel. This gumminess causes stainless steel to smear. However, with the right speeds and feeds, a product like Xebec ceramic fiber can accomplish quality deburring with stainless steel.

Extremely hard materials, such as cobalt chrome, can be more challenging to deburr and will wear faster on deburring and finishing tools. Xebec tools can achieve the work, but you can extend tool life and optimize your results by improving processes that occur before deburring. Your milling process, for instance, can be optimized to reduce burrs.

The hardness of your material will also help you determine the right brush type to achieve the grinding power required for your application. Xebec has a range of brush options from softer brushes that are ideal for resin and plastics to the hardest brushes that are ideal for stainless steel and cast metal.

Composite metal challenges consistency

Composites, such as alloys and polymers, can be difficult to deburr, grind and polish consistently. You want to ensure you have the right tools and processes in place to account for varying material characteristics within the composite.

For instance, titanium alloys can be hard to deburr due to the nature of the composite mixtures and coatings. Conventional cutting tools might not work consistently with these different materials. There may be layers of soft and hard materials that standard abrasives cannot deburr at the same quality, and each layer will generate burrs differently. Consistent cutting action from ceramic fiber brushes that act as cutting tools, along with no deformation of the bristles, means a more consistent finish on all materials. This is especially true of very hard materials that typical deburring abrasives cannot deal with adequately.

Plastics and carbon fiber parts also have such layers, which could easily complicate the deburring process. And cast irons often have glass and other hard materials in the composite which can leave inconsistencies and burrs behind after machining.

Traditional abrasives don’t cut it

Traditional abrasives smear and can leave a residue on the part in the milling and drilling process, which is detrimental on critical parts for medical, aerospace and energy. They also take longer to remove layers of material in the grinding process. Deformation of the tool, as it wears, also yields inconsistent results. They remove small amounts at a time, whereas advanced cutting tools such as Xebec ceramic fiber brushes can remove material faster and more efficiently with repeatable consistency.

The deburring process with Xebec

Xebec products are extremely accomplished with a wide range of materials (up to 65 HRC). Here are just a few examples.

304 Steel: This “food-grade” stainless steel is corrosion-resistant and performs well when machined. In one use case, a manufacturer automated the deburring of 304 steel industrial robot parts with the Xebec Back Burr Path for Tapped Hole. The manufacturer took a five-step process down to three steps, took deburring time per workpiece from 105-120 seconds to 40 seconds, and reduced tooling cost.

Titanium Alloy: A manufacturer needed to deburr artificial hip joints made of titanium alloy. With the Xebec Surface Brush, the manufacturer fully automated polishing and enabled the complete removal of cutter marks with improvement of the surface quality.

SCM (Carbon chromium molybdenum alloy steel): A manufacturer used the Xebec Surface Brush and a Xebec Floating Holder on an injector body shoulder made of SCM for the automotive industry. The manufacturer achieved the complete removal of burrs. Surface roughness of the processed area also improved.

Aluminum and plastic based complex material: A manufacturer needed to work with a smartphone body made of aluminum and plastic. They fully automated deburring with the Xebec Surface Brush and achieve stable, efficient deburring.

Ceramic: Previously, polishing of this brittle material was done by sandpaper, which damaged the edge shape. The sandpapers wore out easily and required frequent replacement. Xebec brushes simplified deburring by moving tools across the groove resulting in a consistent and stable edge quality.

Cobalt-Chromium Alloy: The manufacturer was using a grindstone with sandpaper for removal of cutter marks and polishing of a convex medical part after the end milling process, which was time-intensive and resulted in unstable quality. After implementing automated deburring with Xebec, a consistent high-quality result was realized in a shorter cycle time.

If you have an opportunity to work with a new material, improve an existing deburring process or master a challenging material that’s already giving you headaches, get in touch.

Let team of seasoned experts be the secret to your deburring success and help you identify the best approach to optimize outcomes.