Automated XEBEC ceramic fiber brushes make deburring and polishing a one-step process….

Manual Deburring

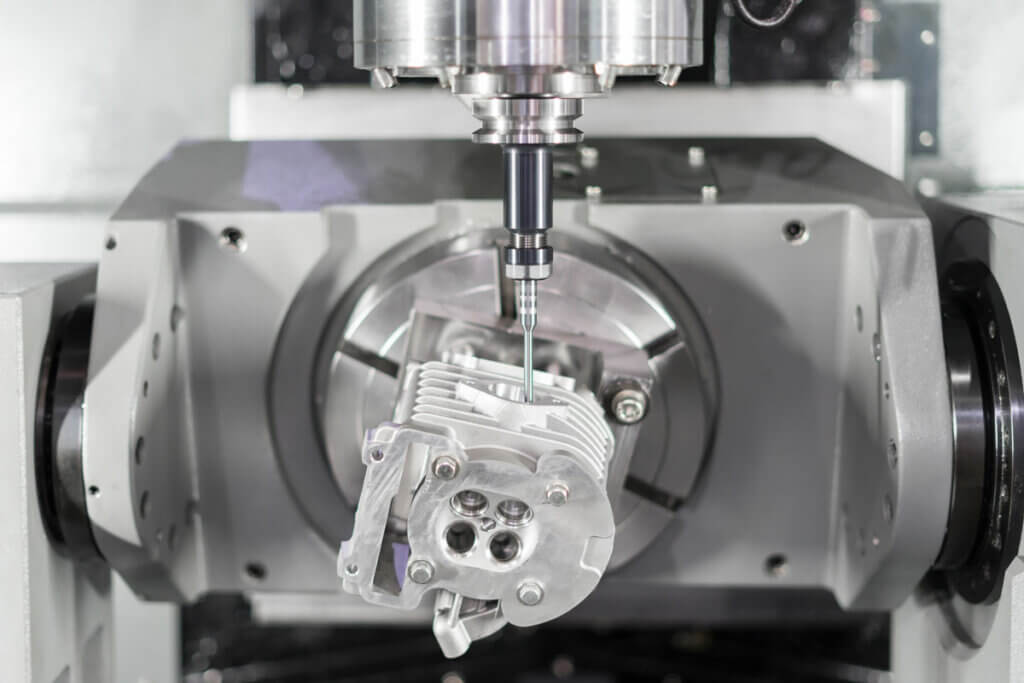

Invest in automated deburring and finishing tools by Xebec to improve metalworking safety and eliminate machine shop safety hazards….

Deburring and finishing after-market parts in the firearms industry is typically a complex and tedious process. The detail of the work and the feel of the finish is incredibly important to maintaining a reputation for high quality, precision and…

Xebec Stone™ Flexible Shaft has grinding power on the entire surface of the head portion. The stone is formed from self-sharpening continuous ceramic fibers and mounted on a flexible shaft. It is available in ball and cylinder style heads….