How Xebec Tools Spark Productivity and Profitability for Energy Industry Manufacturers

Energy and electrical power make the modern world go round. Whether you’re involved in traditional energy enterprises or those focused on renewable resources, the demand for energy is strong – and consumption is only increasing. Yet, challenges riddle the industry, from raw supply to production and delivery. As industry leaders turn to various technologies to smooth out the kinks, changes that are seemingly small often have the largest impact.

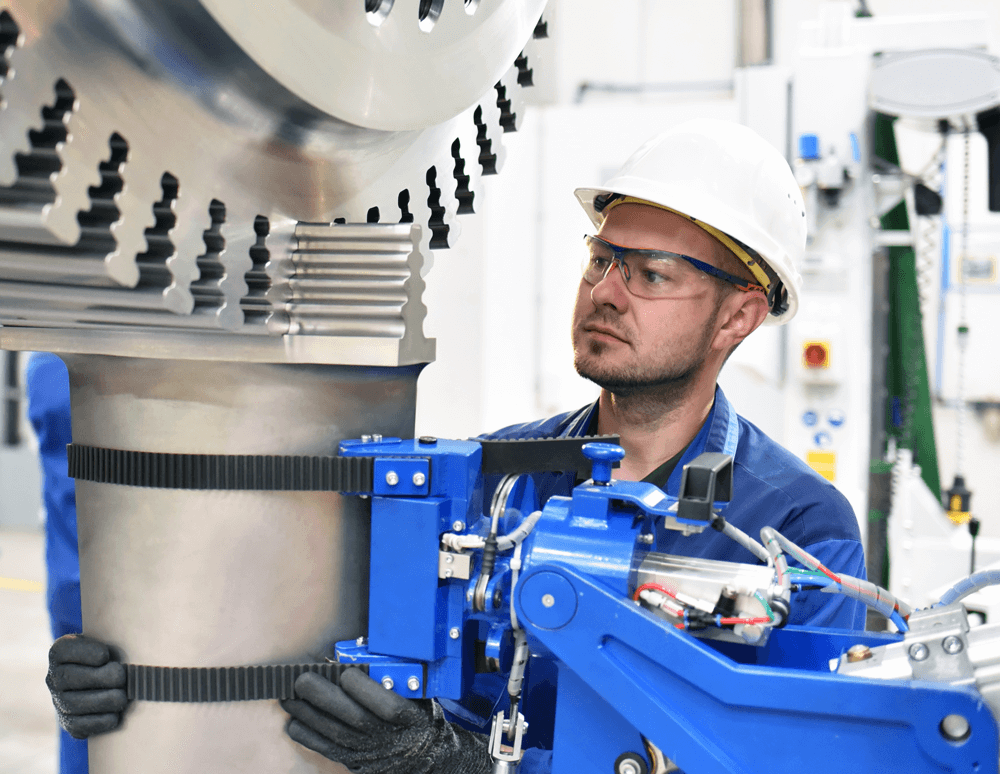

For instance, if you’re trying to keep pace with demand but you’re pulling operators off machines to hand-deburr and finish parts, automating that work with a Xebec ceramic fiber deburring brush will make a drastic difference.

- That operator can now focus on keeping machines running and production optimal.

- You can reduce overall production time and handling, as Xebec ceramic fiber brushes perform deburring and finishing at the same time.

- You’ll achieve more consistent, quality outcomes with durable ceramic fiber tools.

- You can save on the costs of rework and scrap that often result from manual deburring.

- Operators and other employees will be relieved of the strenuous, sometimes dangerous work of deburring by hand, reducing operating costs.

And that’s just scratching the surface.

Such benefits are appealing at a time when expectations for quality and precision are rising as quickly as demand for energy itself, yet difficulties with hiring, sourcing and meeting production timelines persist.

Some challenges are common across industries, as we discuss in our eBook. >>

Why Drop Manual Deburring in Energy Sector Manufacturing?

Manual processes that can be automated hold energy industry manufacturers and job shops back. It’s difficult to achieve consistency from one person, one day or even one part to another. With manual deburring and finishing, you’ll likely encounter issues such as:

- Poor precision, particularly with edge breaks

- Inconsistency from one part to another for both deburring and finishing

- Higher rate of scrap and rework

- More time spent on quality inspections to identify concerns

Learn more about the costs and concerns related to manual deburring and finishing. >>

Instead, energy industry manufacturers can automate deburring and finishing with Xebec tools. These tools can be used on a variety of different materials, from metals to polymers and composites. They accomplish the quality and precision required and can achieve tight tolerances.

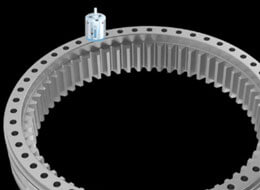

Xebec ceramic fiber brushes work more like cutting tools than other deburring brushes and they won’t deform, allowing for greater consistency, a longer tool life, quality finishes and more. They can improve your operations and outcomes whether you produce components and assemblies for oil and gas, wind, natural gas, solar, etc.

Blades

Channel plates

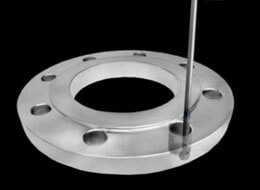

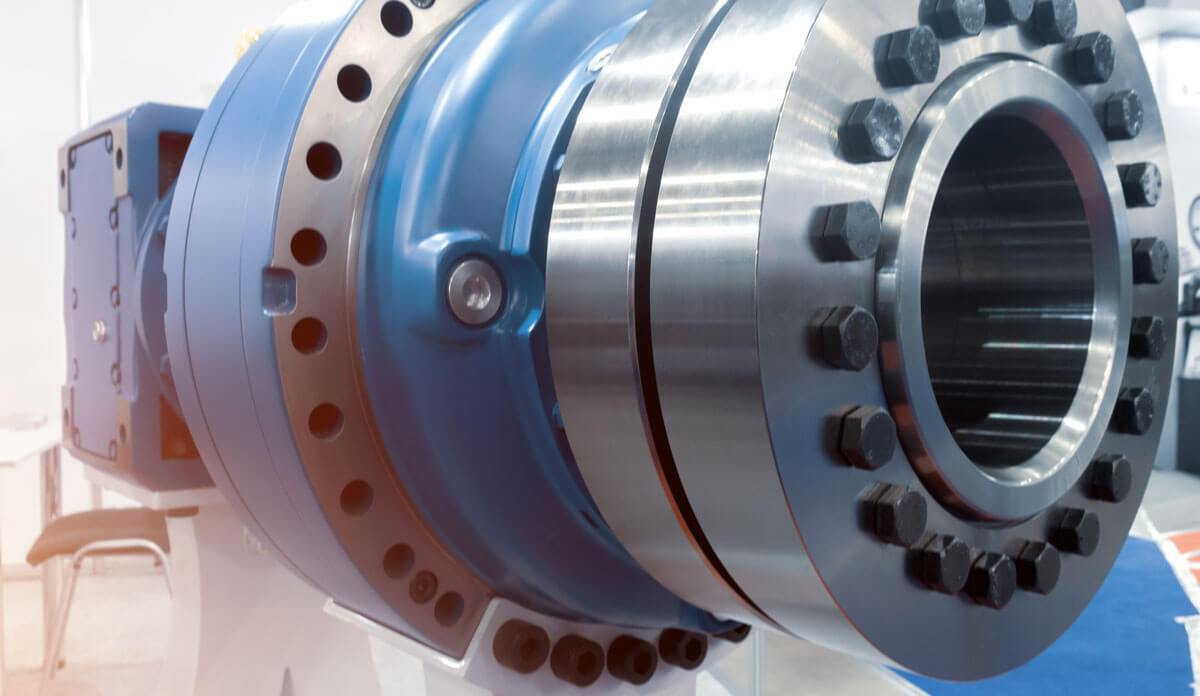

Flanges

Gears

Piping

Pitch Rings

Shafts

Threaded Compressor Fittings

Turbine Vanes

Valve Plates

Learn more about successful applications for Xebec tools in the energy industry. >>

Xebec tools have been successfully applied in manufacturing components for wind turbines, fluid power systems, solar panels and more. They’ve also been used in reconditioning applications for oil and gas components. The applications are endless for Xebec solutions for manufacturers in the energy sector.

Check out more use cases for Xebec Deburring Technologies by industry sector. >>

Use Case: Fluid Power & Motion Control Part Manufacturing

Xebec Deburring Technologies are critical for many manufacturers in the fluid power and motion control industry. Fluid power plays a major role in the economy. And a failure in an assembly, such as hydraulic or pneumatic assemblies, could have devastating consequences. Burrs that aren’t fully removed or finishes that aren’t exactly to spec could result in problems such as:

- Loose burrs in the assembly that cause damage

- Poor seal that leaks or contaminates

- Imprecise edge break that compromises secure assembly

When manufacturers manually deburr and finish parts for the fluid power industry, it’s difficult to achieve the required quality on a consistent and reliable basis. It’s easier to miss a burr or make an error.

With automated deburring and finishing, manufacturers can more confidently hand off quality parts to their customers and significantly lessen the worries about part failure.

Learn more about critical parts in Fluid Power and Motion Control. >>

Xebec Helps Energy Industry Manufacturers Take Charge of Challenges

A simple, yet innovative switch to Xebec tools can help relieve some of the strain energy industry manufacturers are experiencing today. Whether you’re upgrading from a manual process or a less durable and precise automated tool, you’ll realize time and cost savings from the sheer performance of Xebec products. Then there’s the savings from making better use of your resources, keeping your machines running optimally, reducing scrap and rework and even taking on more work with your newfound efficiencies.

Labor Shortage and Retention Concerns

The energy sector is no stranger to the labor shortages plaguing all manufacturing industries. The last thing you want is to have to pause or reduce operations because you can’t fill a spot, or to keep pulling operators and even engineers away from their work to hand-deburr and -finish parts. Automating deburring and finishing is an easy way to relieve some of the tension of being tightly staffed.

What other tactics can you implement to counter the labor shortage? >>

If you do have staff dedicated to manual deburring, automating that process will mean you can upskill and cross-train those individuals to fill other critical gaps in your operations. Upskilling also gives employees improved career prospects at your company, making your roles more attractive and increasing employee satisfaction and retention.

Upskilling is trending upward – but what does it look like in manufacturing? >>

Customer Expectations vs. Operational Realities

As we mentioned before, energy industry leaders must juggle meeting increased demand for the product. They’re also experiencing the increased pressures of regulations and standards. Manufacturers are expected to produce parts to tighter spec, increase capacity and throughput and meet industry standards – and achieving this is a challenge in and of itself.

As an example, expectations for surface finishes in the industry are precise and exacting, and it’s hard to be consistent without advanced, automated tools.

Automating will make the processes of deburring and finishing more efficient, faster and more cost-effective. It will help energy industry manufacturers get closer to their goals to optimize operations, so they remain profitable and productive while satisfying customer and industry expectations.

Running lean is often part of manufacturers’ strategies to optimize operations. >>

ROI on Automated Deburring for Energy Industry Manufacturers

What do you really stand to save and gain from automating deburring and finishing with Xebec tools at your facility?

Save Net Production Time

While it may feel counter-intuitive that adding time on the CNC machine saves time overall, but it’s true. Moving deburring and finishing processes onto the machine could add anywhere from a few seconds to a few minutes to the cycle time. However, that might’ve taken several hours to work by hand. Consider the following:

- The time it takes to deburr and finish by hand is drastically longer than automated in the machine.

- Even against other automated tools in a machine, Xebec Deburring Technologies outperform on time.

- More consistent outcomes with Xebec tools will shorten – or even eliminate – some of your quality inspection work.

At the end of the day, Xebec tools can cut total production time by up to 80%.

Realize Returns You Can Re-Invest

Manual deburring and finishing don’t just waste time – they cost more than is necessary in this modern age. And that’s not just in the direct costs of labor and tools (though the tool costs for consumables can get remarkably high when you add them up at the end of the month). You must also account for potential injuries from manual work, the costs of scrap and rework, missed opportunities from running on tight resources with manual technology, and more.

With automated deburring and finishing, you eliminate several cost risks and optimize your capital on tools, labor and materials. In one estimated cost comparison, CNC machine deburring cost five cents per piece compared to 46 cents per piece when manually deburring.

When you calculate your deburring cost and ROI, what do you factor for? >>

Automated Deburring: A Small Step Toward Modern Manufacturing

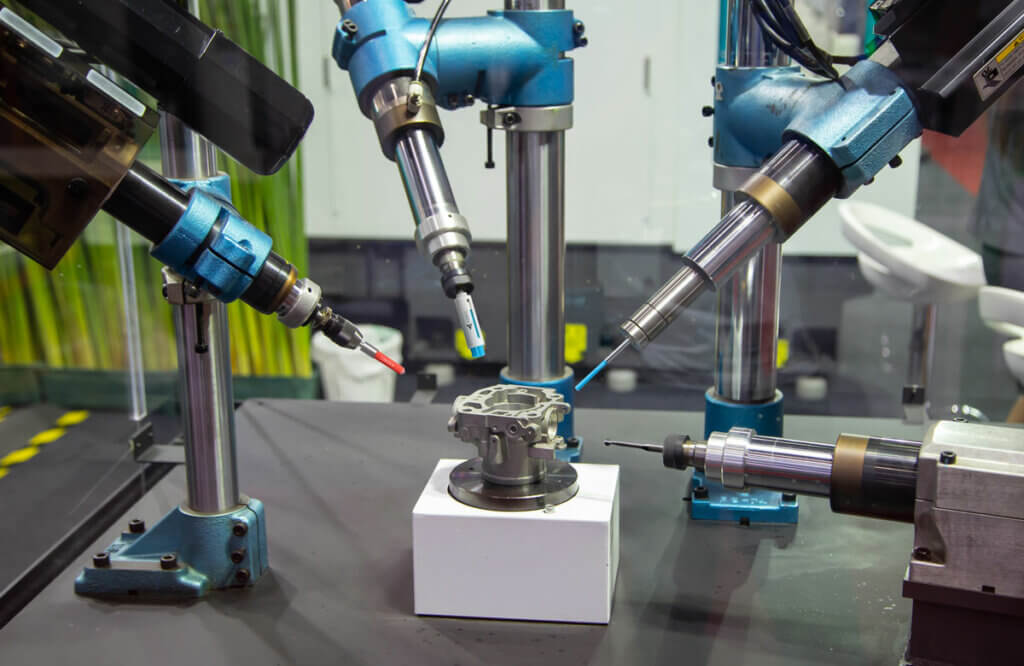

Automating deburring and finishing can fit perfectly into plans to modernize your manufacturing processes. For example, Xebec deburring tools can be used to deburr parts produced using additive manufacturing, making the entire process more efficient and future-forward. Additionally, Xebec Deburring Technologies can be automated in CNC machines as well as with robotics, depending on the application.

Automating these processes in a machine or with robots is also a step toward achieving done-in-one machining. With such an approach, you reduce the times a part needs to be handled or re-fixtured and improve efficiency throughout the production process.

Learn more about designing a done-in-one machining process. >>

Importantly, the Xebec team encourages energy industry manufacturers to get in touch with our application experts before implementing Xebec tools in a process. Our application expertise can go a long way in ensuring you achieve the highest quality results, faster and more efficiently. Don’t go it alone! Get in touch with one of our experts to discuss your application.

See why our application expertise is the real secret to deburring success. >>

Do you manufacture parts for the Energy Sector?

Contact us to discuss your application and download our comprehensive eBook, Advanced Manufacturing Solutions for Energy Parts.