Surface finishing plays a critical role in machining, influencing the appearance and functionality of the finished part. You can achieve more reliable and consistent finishes by understanding the fundamentals of surface finishing, the symbols used in technical drawings and the role hardness plays in surface finish.

What is Surface Finish in Machining?

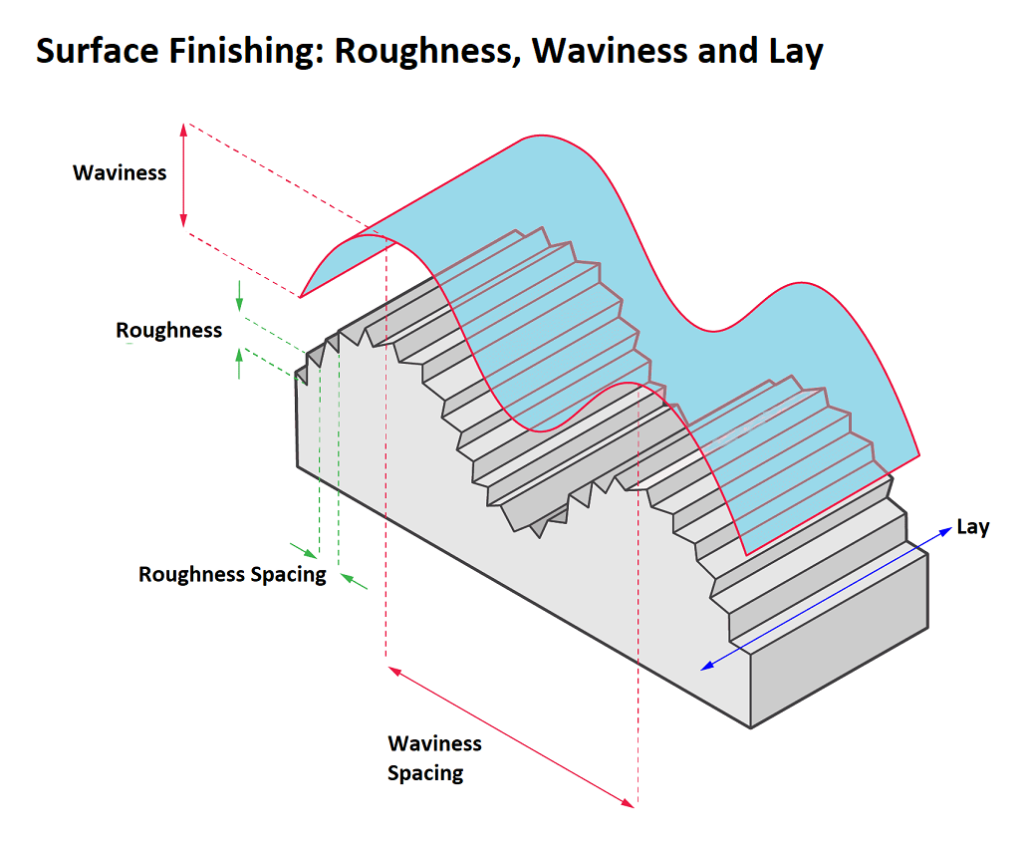

Surface finish describes the texture of a surface on a machined part and may also be interchangeably called surface texture. Three elements determine a part’s surface finish: roughness, waviness and lay. Let’s define:

- Roughness: Measures the closely spaced variations left by cutting tools or grinding wheels in the surface texture. Roughness is often expressed with a unit of Roughness Average (Ra), using a profilometer to show variations in surface height.

- Waviness: Measurement of the more widely spaced component of surface texture and indicates periodic variations in surface finish. Variations could be due to machining flaws and warping from heat and cold.

- Lay: Direction of the dominant texture pattern on the surface. A circular pattern is most common but patterns can be parallel, perpendicular, radial, or cross-hatched, to name a few.

The most common units of measurement for material roughness are Ra and Rz.

Ra (Average Roughness): Commonly used for specifying roughness.

Rz (Average Maximum Height of the Profile): Describes the peak-to-valley heights.

Surface finishing involves removing or reshaping the material to achieve a specific roughness noted in a technical drawing. Having the right tools helps achieve the desired surface texture, smoothness and integrity for proper functionality, performance and longevity of your machined parts.

>> Learn more about surface finishing processes.

Why Surface Finish Matters in Machining

When parts fail to meet their desired surface finish, impacts can be diminished aesthetic value or tactile experience of a product, implications for subsequent manufacturing processes and lesser quality and effectiveness of the completed assembly.

Poor surface finish can result in:

- Degraded adhesion, coverage or coating durability of paint, powder coating or electrocoating.

- Unreliable bonding with adhesives.

- Decreased quality of welds.

- Uneven or rough surfaces requiring additional material removal.

- Reduced effectiveness of shot peening, polishing and anodizing.

- Negatively impacted part tolerances and fits.

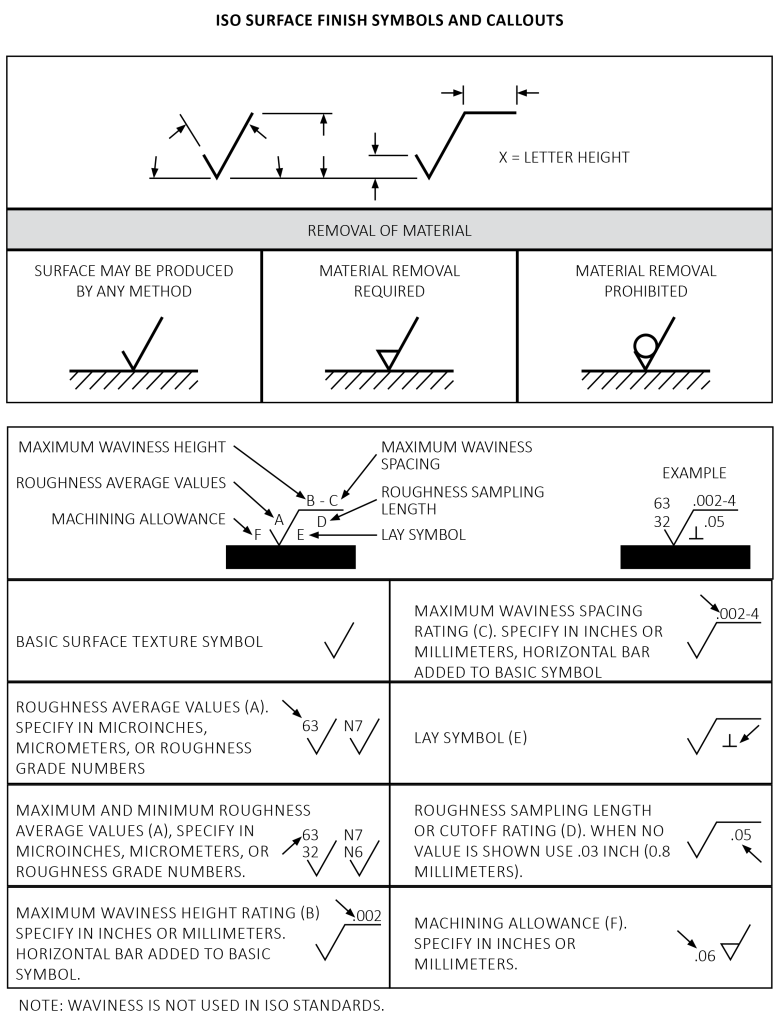

What are Surface Finish Symbols?

Surface finish symbols are standardized notations used in technical drawings to specify the desired texture or smoothness when machining a part’s surface. Essentially, they are variations of check marks that provide information to the machinist about the desired surface characteristics and manufacturing process.

Note: The International Organization for Standardization (ISO) 1302:2002 standard defines these symbols widely adopted in engineering and manufacturing. The American Society of Mechanical Engineers (ASME) has published standards, specifications, definitions and measurement methods for industry continuity.

Understanding Hardness in Machining

Hardness refers to a material’s resistance to deformation, indentation, or scratching. Hardness is a critical property in machining that influences tool selection, cutting parameters and overall machining efficiency. Standard hardness testing methods include Brinell, Rockwell, and Vickers. Each are suitable for different materials and applications.

Brinell Hardness Test: This test uses a hardened steel or carbide ball indenter pressed into the material under a specific load. The diameter of the resulting indentation is measured to determine hardness.

Rockwell Hardness Test: This test measures the depth of indentation under a large load compared to the depth under a preliminary load. Different scales (e.g., Rockwell B, Rockwell C) are used depending on the material.

Vickers Hardness Test: This test employs a diamond pyramid indenter to assess hardness, suitable for all metals and materials.

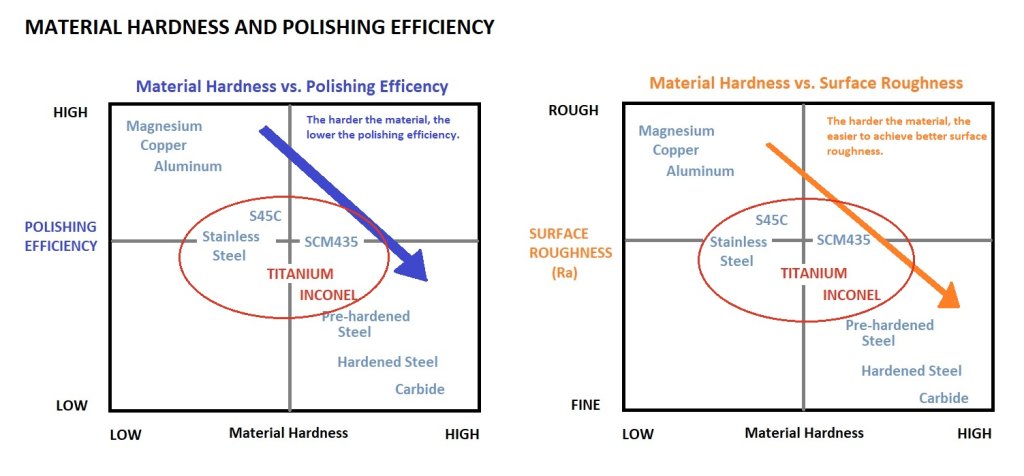

Harder materials may require stronger tools and slower speeds, while softer materials can deform easily. The parameter of material hardness impacts the material removal rate (feed and speed), the machine’s power consumption and the tool’s lifespan.

Apart from helping you determine the feeds and speeds needed to achieve the proper surface finish, hardness determines the part’s resistance to wear and fatigue, and its overall strength post-machining.

How Surface Finish and Hardness Relate to Each Other

Surface finish and hardness are often interdependent for achieving the right surface finish. Here’s how:

- Hard Materials: Harder materials resist deformation and wear, allowing for a finer, more consistent surface finish. However, they are more challenging to machine and require precise tools and settings.

- Soft Materials: Softer materials are easier to machine but can deform or tear during cutting, which may lead to rough or uneven surface finishes. Proper tool selection and speed adjustments are critical to achieve a smooth finish.

Understanding and effectively utilizing surface finish symbols and hardness testing methods are fundamental in machining. Tools like Xebec ceramic fiber deburring tools further assist in achieving the desired surface quality, ensuring that parts perform optimally in their intended applications.

Achieve the Best Surface Finish with Xebec Ceramic Fiber Deburring Tools

Xebec Deburring Technologies helps manufacturers and machine shops meet stringent surface finish specifications efficiently, enhancing product quality and performance.

Xebec ceramic fiber deburring tools are designed to enhance surface finishes by effectively removing burrs and achieving precise surface textures. These tools offer several benefits:

- Precision Finishing: Xebec tools help achieve fine surface finishes to the specified standards in technical drawings with consistent and uniform surface finishes, meeting specific roughness requirements.

- Material Compatibility: Xebec tools are suitable for various materials, including metals and composites, ensuring versatility across different applications while maintaining surface integrity.

- Consistent Results: The flexibility and abrasiveness of ceramic fibers ensure consistent, uniform finishes across multiple parts.

- Reduced Rework and Scrapping: Xebec tools minimize the need for additional processing steps, saving time and reducing costs. By achieving the desired finish in the initial pass, there are fewer incidences of rework and lower scrap rates.

- Cost-Effectiveness: Xebec tools reduce downtime and tooling costs, while improving production efficiency.

Need to remove tool marks? Beyond function alone, some manufacturers are prioritizing the aesthetic look of the part to meet customer expectations.

Successful Applications Using Xebec for Better Surface Finish

Check out these real-world examples of machine shops or manufacturers using Xebec tools to achieve ideal surface finishes.

Medical Device Manufacturer

Parts and devices for the medical industry typically demand tight dimensional tolerances regarding angles, roundness, diameter and contact ratios, and more. Any deviations from these requirements can result in ineffective parts.

One Xebec customer manufactures artificial hip joints, and precision is required on the surface finishes of the hip sockets and hip stems with ball joints. The specific angles, straightness, roundness and diameter tolerances must allow for smooth performance and proper fit. Xebec tools enabled this manufacturer to remove cutter marks and provide improved surface quality.

>> How medical manufacturers can increase the quality & efficiency of surface finishing.

Precision Manufacturer

Machine shops have unique challenges in that the amount of labor, scrap and rework must be dialed into each run for capacity and productivity. Each run must yield consistent and high-quality parts to be profitable.

One Xebec customer had previously been using a crane to move an extremely heavy part from the milling and cutting area to the grinding area. When they implemented Xebec ceramic brushes at the end of their milling and cutting processes, they eliminated six hours per part in travel and grinding—saving $600 to $800 per part.

>> How machine shops can increase the quality and efficiency of surface finishing.

Powertrain Manufacturer

Powertrain industry manufacturers deal with components ranging in size and complexity for a number of different end users.

One Xebec customer had been deburring their oil pans with a wire brush, resulting in inefficiency and scratches left behind. Once they implemented the automated Xebec brush, not only did they save time, the oil pans had improved surface quality and yielded better outcomes.

>> How powertrain manufacturers can increase the quality and efficiency of surface finishing.

Conclusion

Xebec ceramic fiber deburring tools can streamline your finishing process, ensuring manufacturers and machine shops can precisely meet specifications for surface finish. We recommend surface finishing with Xebec for the following results:

- Improved surface finish—both visually and functionally.

- Consistent and precise results that are to-spec.

- Faster finishing process than manual or automated alternatives.

- Consolidation of deburring and finishing, reducing wasted tools and time.

- Opportunities to reallocate labor more effectively.

- Reduced rework and scrap.

Contact us to see how we can help you design the ideal surface finishing solution for your business.