Xebec Deburring Technologies had the opportunity to publish an article in Industrial Equipment News (IEN). Check out the article in IEN: Modern Methods to Deburr Cross-Holes without the Headache.

Deburring cross holes—removing unwanted material from intersecting drilled holes—is a critical yet challenging task in manufacturing. Traditional manual methods often lead to inconsistent results and increased labor costs. However, advancements in automated deburring tools offer efficient and reliable alternatives.

In the article, we offer strategies for manufacturers and machine shops to overcome common challenges with cross-hole deburring, including insights on:

- The challenges of manual deburring

- Difficulty accessing and effectively removing burrs in complex cross hole geometries.

- Inconsistencies in quality due to the variability of manual processes.

- Higher labor costs and potential for employee injury or dissatisfaction.

- Advantages and Benefits of Automated Deburring

- Consistent and repeatable results, enhancing overall product quality.

- Increased productivity by reducing manual intervention and associated labor costs.

- Improved safety and employee satisfaction by minimizing repetitive manual tasks.

- Selecting the Right Automated Tool

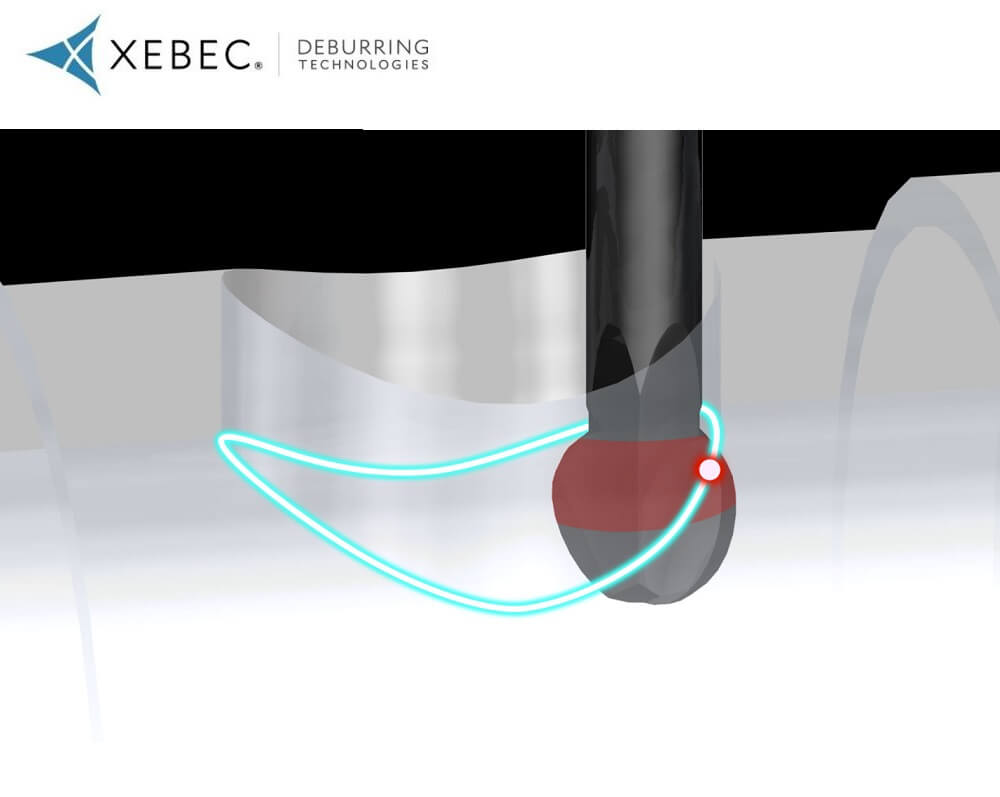

- Consider tools specifically designed for cross-hole deburring, capable of handling complex shapes and varying diameters.

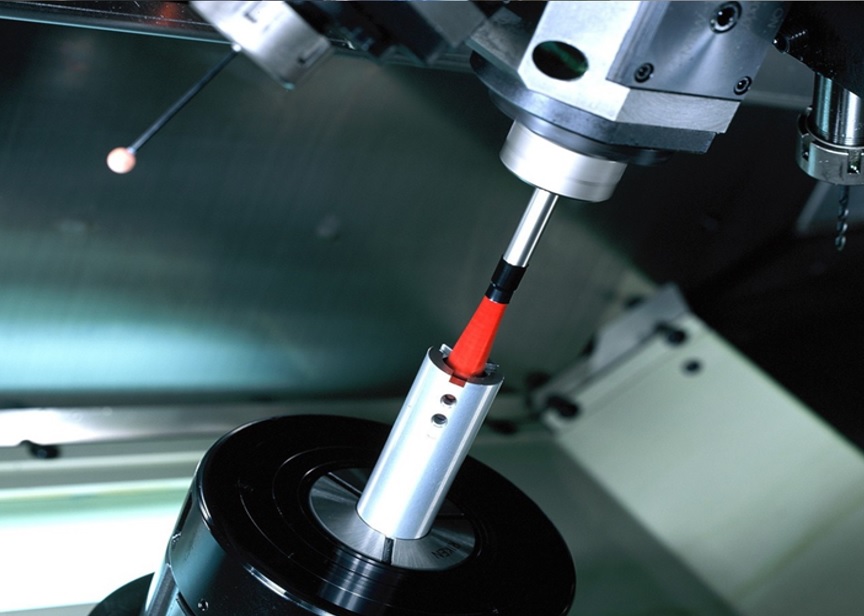

- Evaluate the tool’s compatibility with your existing equipment and its ability to integrate seamlessly into your production process.

- Assess the tool’s performance on different materials and its adaptability to various part geometries.

>> Learn more in our CNC Cross-hole Deburring Guide

See an example of Xebec performance in this video of automated cross-hole deburring and polishing on various hole types and shapes:

For more information about Xebec’s deburring solutions and success, visit our Successful Applications page. And check out our blog on ways to reduce production challenges with automated deburring technology.