Burrs have been thorns in metalworkers’ sides since ancient times. Yet, just as the technologies used to craft and manufacture components have advanced, so have the technologies used to remove burrs. In fact, they’ve advanced leaps and bounds in just the past decade. Manufacturers today shouldn’t use yesterday’s assumptions about deburring considering today’s technologies.

With today’s technologies like Xebec ceramic fiber brushes, you can reduce how much of a nuisance burrs are in the first place. You can control how burrs are formed during the machining process, making them easier to remove. This will reduce the deburring time required and broaden your options for deburring methods.

For instance, Xebec automated deburring tools are capable of deburring a broad range of materials and burr types. However, they have limits. The ideal target burr size for a Xebec surface brush is 0.008” burr root thickness or less, and our tools cannot deburr pushed materials. However, you can adjust your processes to form more workable burrs for automated deburring.

This is a worthwhile upgrade for most manufacturers. Automating deburring and finishing drastically improves quality, speed and reliability. At Xebec, our application specialists can help you make critical process changes that allow you to automate deburring and reap its many benefits. The first step is understanding what types of burrs you’re working with now. Then, you can determine the best approach to optimizing them.

See the robotic deburring of a part using a Xebec ceramic fiber brush:

Burr Types in Machining and Molding

Different types of burrs are produced by different processes and machining conditions.

Rollover burrs

Rollover burrs (or exit burrs) form on the exit side of the machining process as the material rolls with the tool, is pushed over an edge and is retained. The thickness of these burrs will depend on the depth of cut.

Poisson burrs

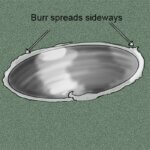

Poisson burrs form on the entrance side of the machining process, where the tool first touches the surface and deforms the material. The material is pushed away at the edge in a perpendicular direction.

Tear burrs

Tear burrs form when material is torn away from the part being worked as opposed to cut away, leaving material behind. You’re most likely to see tear burrs from a punching method.

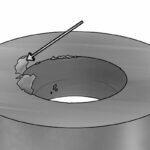

Breakout / Cut Off burrs

Also known as cut-off or breakoff burrs, these burrs are left behind when a cut piece breaks away from the part being worked. You’re most likely to see breakout burrs from “saw cuts and automatic screw machine parts.”

Burr Type Image Source: Burr formation and its treatments–A review, The International Journal of Advanced Manufacturing Technology March 2020

Thermal burrs

Thermal burrs form during thermal processes such as welding, molding and laser cutting. They’re also known as slags or spatters.

Burr Classifications

Every manufacturer and industry used to define burrs in their own way, so manufacturers and engineers began to develop such a standard for classifying burrs. This standard was quickly adopted and the result is the following five classifications:

Class 1 – “micro burrs” that can only be seen with magnification.

Class 2 – small burrs, also known as “feather burrs” that can be seen with the naked eye.

Class 3 – small but well attached burrs.

Class 4 – large and well attached burrs.

Class 5 – also known as “extruded burrs”, which are not actually burrs, but a deformation of the extruded material produced by drilling.

How Machining Method Affects Burr Type

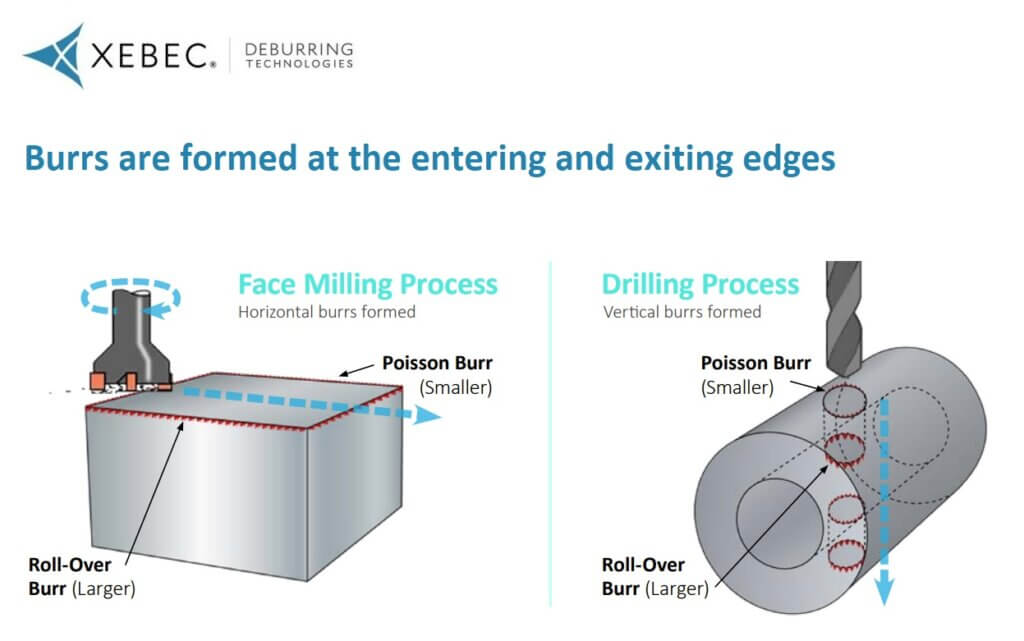

Burrs are formed during processes such as face milling and drilling by the tool angle as it works on the part. The size and type of the burr and its direction will depend on the machine and process used.

For example, during face milling, horizontal burrs can be generated. As the tools begins the face milling process on the entrance side, the resulting horizontal burrs are small and are known as Poisson burrs. As the tool works on the exit side, the resulting burrs are large and known as Rollover burrs. The burr size also depends on the angle the tool meets the edge. The more obtuse an edge, the smaller the burr.

Some examples of how different machining processes can generate different burr types:

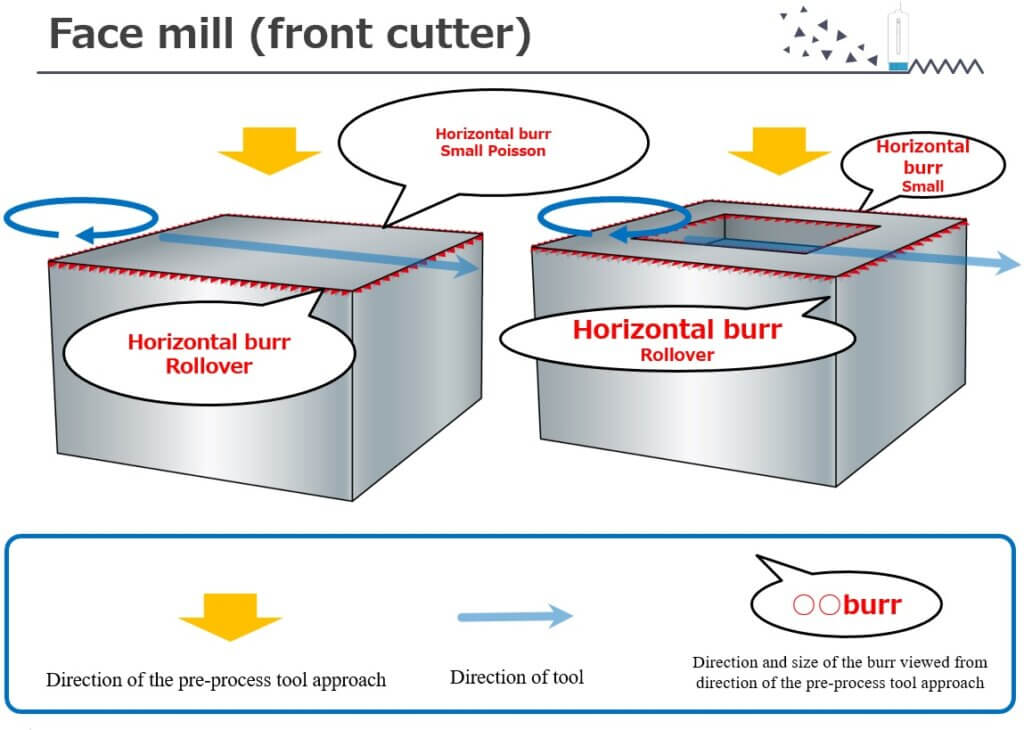

Face milling (front cutter)

This process will produce both Poisson and Rollover burrs. Small horizontal burrs (Poisson) form on the entrance side and large horizontal burrs form on the exit side (Rollover).

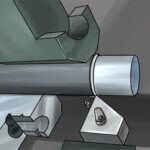

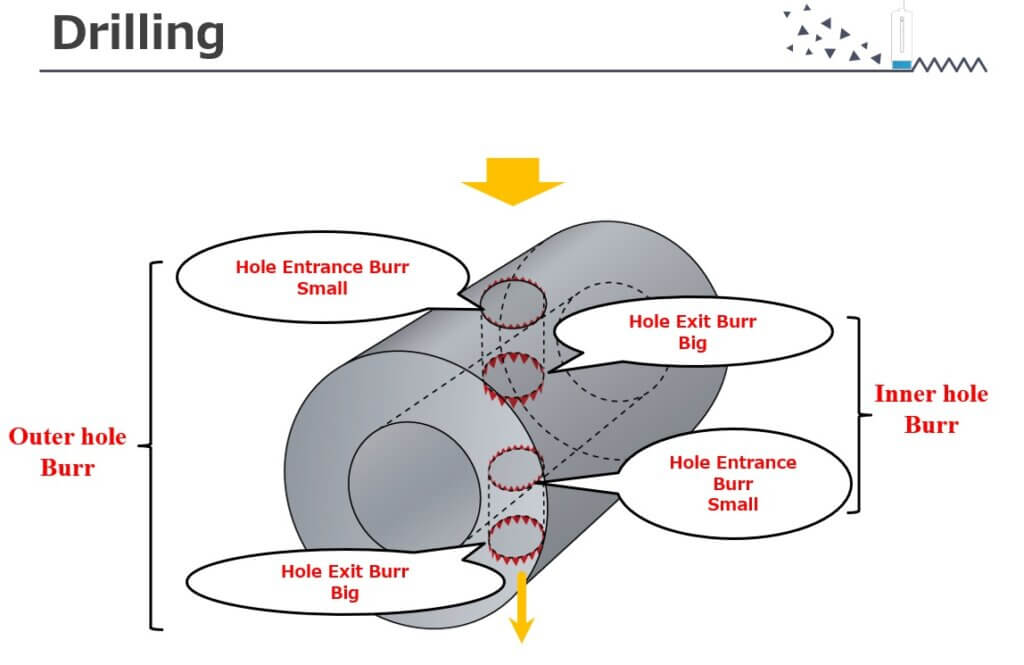

Drilling

This process produces both Poisson and Rollover burrs. Small vertical burrs form on the hole entrance (Poisson) and large vertical burrs form on the exit side (Rollover).

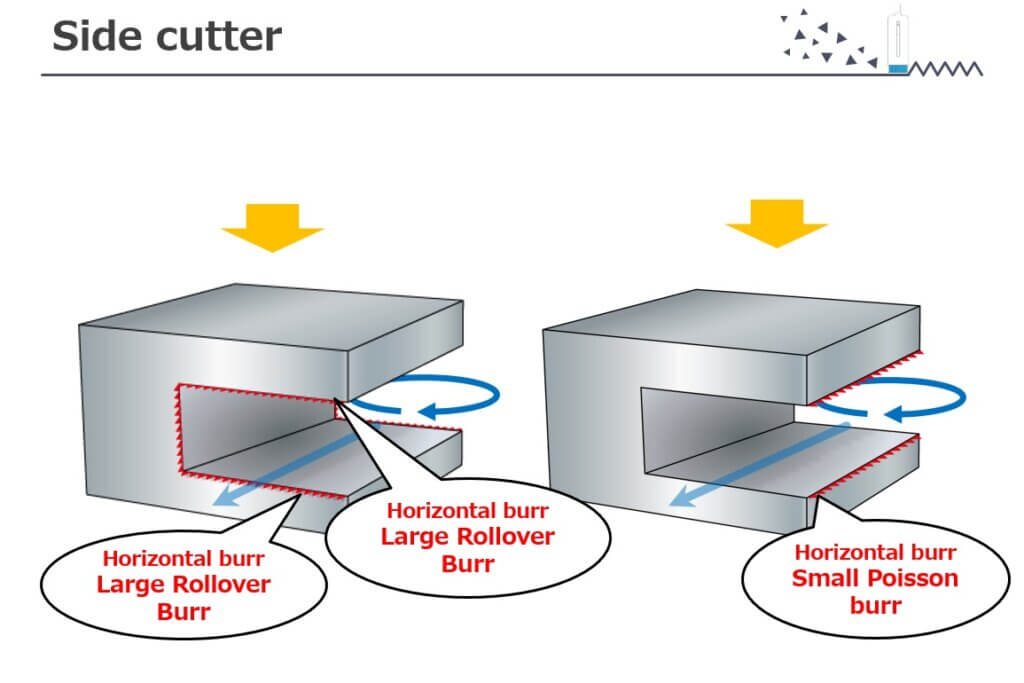

Side cutter

This process will produce both small and large horizontal burrs. The small burrs generated are Poisson burrs and the large are Rollover burrs.

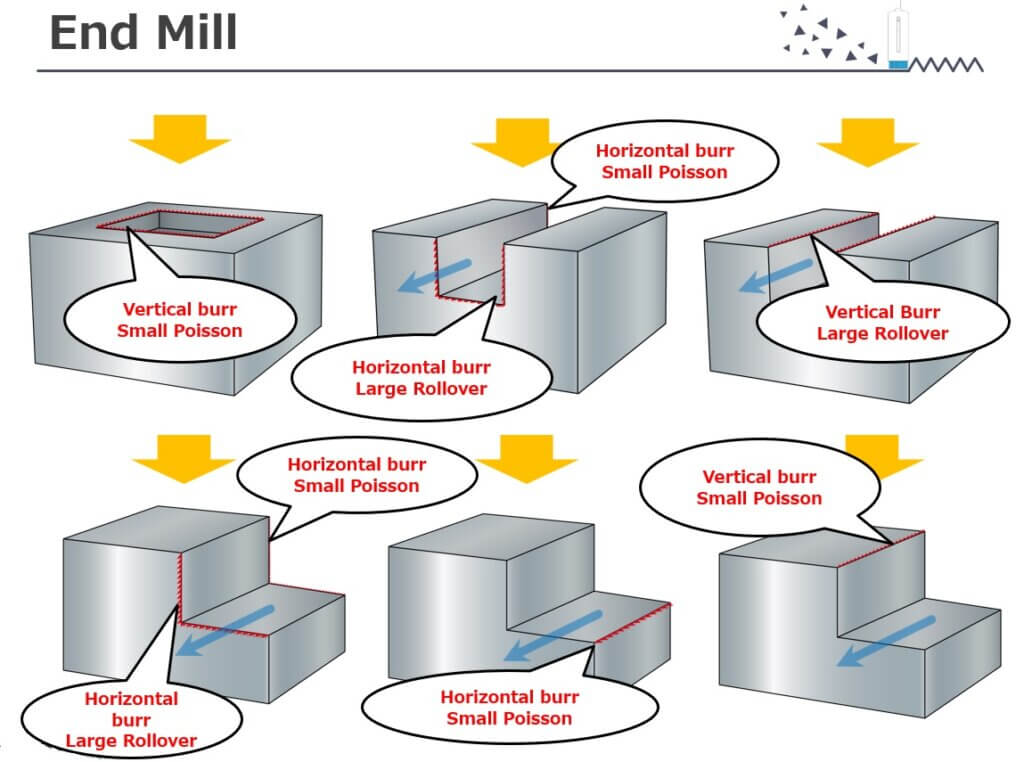

End milling

This process produces both small Poisson and large vertical Rollover burrs as well as small and large horizontal burrs.

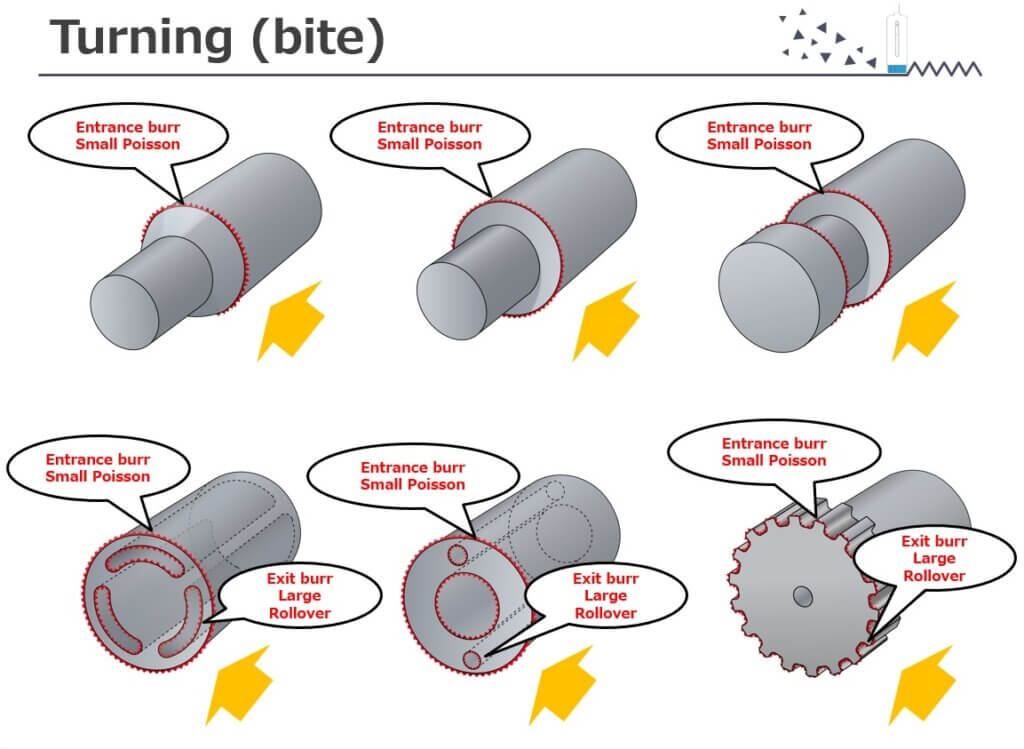

Turning (bite)

This process produces both Poisson and Rollover burrs. It produces small burrs on entrance (Poisson) and large burrs on the exit side (Rollover).

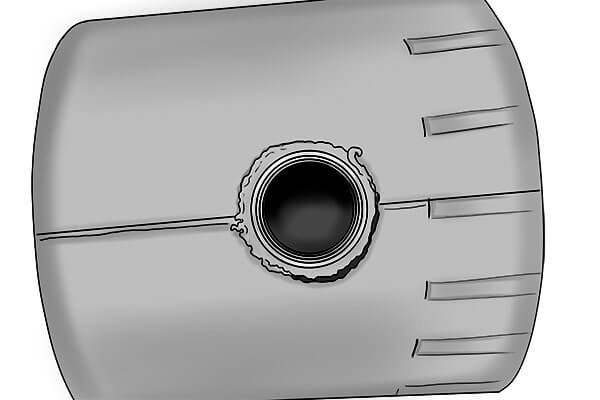

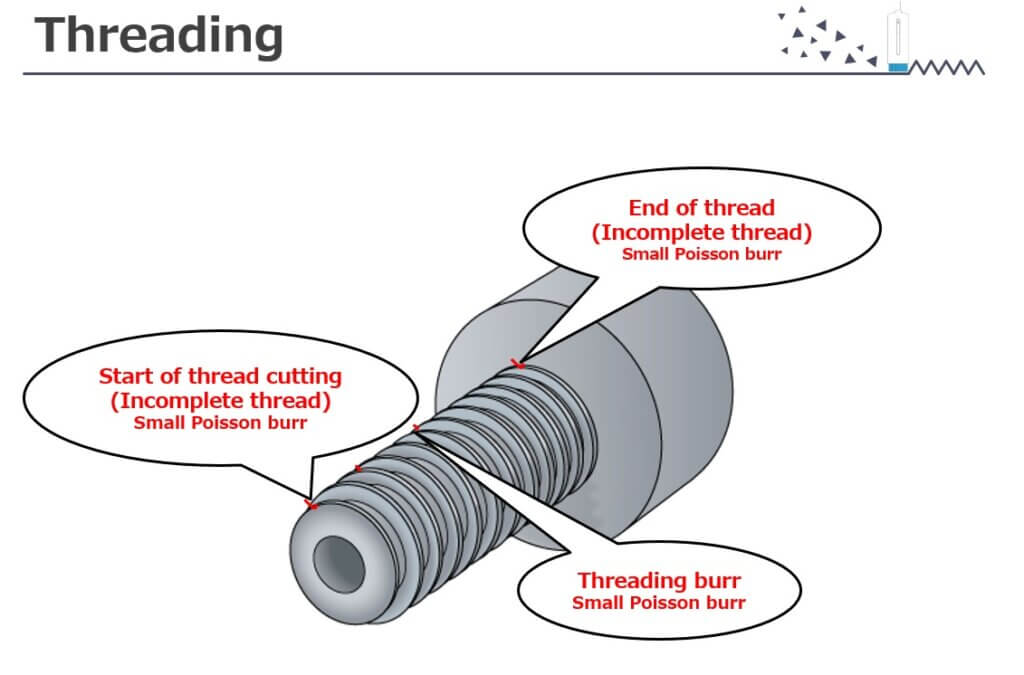

Threading

This process produces small burrs at the start of the thread, on the thread and at the end of the thread.

Thermal

A thermal burr is typically known as slag or dross and occurs during plasma or laser cutting. In laser cutting, the quality of cut is determined by how the laser beam, assist gas, and material interact. Dross or slag can be caused by using overused consumables such as worn cutting tips. Cutting the piece too fast can also generate top dross.

Learn how to do hand-deburring the right way – with Xebec tools >>

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is the process of creating a part by building it one layer at a time. It is the opposite of subtractive manufacturing (such as CNC machining), in which a part is created by removing material from a solid block. 3D printing doesn’t create as many burrs as CNC machining and can often eliminate 25 to 35 percent of the deburring that manufacturers see in CNC machines. However, deburring is still needed and a high-quality finish is still required.

Learn more about surface finishing developments in additive manufacturing >>

Controlling Burr Formation

There are several ways to optimize how burrs turn out from your machining process, including:

- Changing the processing conditions, such as reducing feed rate and cutting allowance.

- Changing the process order, such as end-milling before face-milling.

- Changing the machine tool path, such as face-milling in a clockwise direction to form smaller burrs on the exit side.

- Changing the edge shape or angle to be more obtuse and produce smaller burrs.

- Changing the shape of tool you use, such as using a flat drill versus a conventional drill.

- Replacing worn-out tools, as sharper tools with clean cutting edges will generate smaller burrs.

Learn more in our comprehensive blog on controlling burrs before deburring. >>

We’ve also created a free downloadable checklist: 6 Tips to Help Control Burr Size.

Advantages of Automated Deburring with Xebec vs. Alternatives

Manufacturers have many options when it comes to deburring solutions. However, few deburring brushes and tools compare to the efficiency and quality you can achieve by automating deburring with Xebec ceramic fiber tools that last much longer than competitive options. Some of the most common deburring tools and their downsides include:

- Handheld tools > Slow, tedious and potential for human errors

- Grinding wheels & flap disks > Inconsistent with uneven wear. Expensive due to short life.

- Wire brushes > Bristle deformation, inconsistent results.

- Nylon brushes > Brush wears quickly, short tool life, inconsistent results, leaves a residue.

Learn more about commonly used tools and brushes for deburring. >>

However, each of these options comes with setbacks when removing burrs or providing a reliable consistent finish. They often result in more scrap and rework, and they need to be replaced with greater frequency.

It can be well worth adjusting your processes to allow for automated deburring with Xebec Deburring Technologies. Improving deburring processes with Xebec deburring tools can help you realize:

- Improved quality and reliability

- Reduced time and cost of manual deburring labor

- Ability to reallocate employees to more value-add processes

All of these benefits allow your organization to meet today’s production demands and improve your company’s reputation for consistent and reliable quality.

Learn more on the ROI of automated deburring with Xebec >>

See how Xebec’s Back Burr Cutter can deburr both sides of a cross hole quickly:

If you’re looking to improve your pre-deburring process to enable automated deburring and finishing, reach out to discuss your current conditions with one of our experts.

1 thought on “Burr Basics: Identifying Burr Types to Efficiently Remove”

Hi

Would this system work to de-burr the front and back face of our threaded taps. Like on our web site.

www somta.co.za

Regards

David Atkins

[email protected]