Everywhere you look these days, it seems there’s a different economic outlook for the manufacturing industry.

- In June 2023, CNN reported that manufacturing is sputtering in the United States and across the globe.

- In July 2023, Axios reported there’s been a years-long manufacturing boom in the United States.

As seasoned industry professionals, you know what’s going on here: There’s always nuance in the data, and each source is looking at the data from a different angle.

And, of course, the industry is in such flux that stark changes from one month to the next are now par for the course. That’s why a Google search will reveal that people commonly ask:

“Is manufacturing slowing down?”

…and

“Is manufacturing making a comeback?”

With an outlook like this, it pays to build resilience into your business so you’re always ready in the face of uncertainty. But how do you know which strategies truly build resilience?

Look at the evidence and trends in your industry and let them be your guide – while factoring in your unique circumstances. In manufacturing, some of the top ways companies are planning for and achieving resilience are:

Paying close attention to cash flow to improve liquidity.

Deloitte’s analysis of companies that performed well through and after a recession revealed that liquidity is the most important factor. Having lower debt and easy access to capital enabled those companies to better support operations and thrive post-recession. Deloitte suggests gaining insights into your own cash flow to improve liquidity at your company, as this will allow you to see risks, opportunities and critical issues.

For example, manufacturers can modernize their deburring and finishing processes to increase productivity and achieve consistent quality results with automated deburring tools from Xebec Deburring Technologies. This productivity strategy improves a company’s liquidity and its ability to react to market conditions much faster.

Making capital investments that target efficiency and productivity.

Deloitte found companies that strategically invested in assets and technologies ahead of a recession performed better in the recovery stage. The key is to target investments that improve efficiency and productivity, such as deburring and finishing with Xebec’s automated tools, allowing you to do more with less. Specifically, Deloitte suggests investing in process-related innovations that optimize production output, inventory and overall costs. As Deloitte states, “Such process innovations could go a long way in helping manufacturers produce more with less, in turn enhancing efficiency and productivity of their assets and employees.”

Prioritizing employee experiences and growth.

The Manufacturer suggests investing in worker retention as a strategy to mitigate economic uncertainty. Your people are a critical component to your resilience. Manufacturers are turning a broader lens on their employees, looking more holistically at employees’ experiences to see how to better nurture them and help them grow. Part of this is optimizing the daily work experience, such as automating arduous and strenuous tasks, and part of it is creating career paths and growth, which becomes more feasible when you automate those tasks that keep employees bogged down. It opens doors for reskilling and upskilling, a strategy Oracle suggests as a means to overcome workforce shortages.

Reducing waste in operations and workflows.

Another strategy The Manufacturer suggests is reducing waste. Such advice could extend across your operations, from processes in your back offices to how your facility is arranged to actual material waste on your shop floor. When you’re working toward resilience, such a step is essential. Wasteful activities cost time and money unnecessarily.

This isn’t the end of trends to help direct your strategies. These and other resources point to sustainability, supply chain optimization, embracing the factory of the future, diversifying your workforce, re-shoring and more.

How Xebec Helps Manufacturers Build Resilience

Across the board, investing in innovative technologies is a proven and recommended strategy for manufacturers to better weather uncertainty. Yet, with so many innovations arriving on the market each day, you want to make the investments that will have the greatest impact on your business overall; investments that will hit multiple marks.

Xebec products check too many boxes to ignore. They automate deburring and finishing reliably, allowing manufacturers to increase throughput, do more with less, better allocate and upskill their workforce, reduce waste and more.

Do more with less with Xebec.

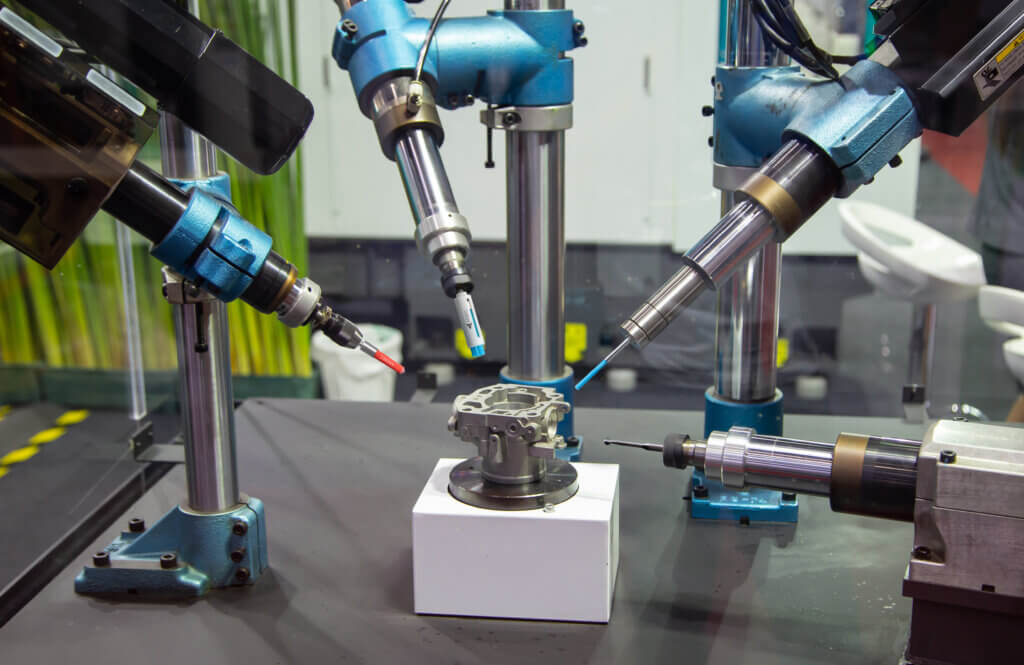

Automating deburring and finishing with Xebec Deburring Technologies allows you to improve productivity with less labor. A Xebec tool on your CNC machine or in a robotic process can perform the work you may be struggling to find labor for, or allow you to move one individual into a more critical role. This is helpful at a time when labor is hard to find and manufacturers need to optimize resource management in their facilities. Plus, Xebec tools don’t need time off or get injured on the job.

Increase your throughput with Xebec.

When you move deburring and finishing onto your CNC machine, you’ll be able to realize increased throughput immediately. Xebec tools work quickly and efficiently, optimizing net production time. This versus manual processes that can take hours and even days to complete – and that’s without delays due to any workforce shortages or other priority work.

Reduce operational and material waste with Xebec.

Automated deburring and finishing with Xebec will optimize your operations, reducing the waste of time and labor that would otherwise go into manual deburring. It will also reduce the amount of scrap you have to toss each day due to inconsistencies with manual processes, damage during handling and other issues on the shop floor. Xebec tools produce quality parts consistently, so you can rely on them to deburr and finish each part as expected.

Nurture employees and enable their growth with Xebec.

Moving employees off of manual deburring and finishing opens the door for you to reallocate them to more revenue-generating tasks, and it presents opportunities to upskill and reskill them. This demonstrates you have a career path and growth opportunities for them, which is key to employee retention. Not only that, but it relieves them of work that is often strenuous and taxing on the mind and body. Further, consider scenarios where your machine operator is doing the deburring. This keeps that operator from being able to perform that higher-revenue work of running machines.

This is just a sample of how an investment in Xebec products can help your business become more resilient. If you’d like to learn more about our deburring tools and how they might fit into your processes, feel free to reach out to our team of experts.