Discover how surface roughness affects performance and compliance. Achieve flawless finishes with XEBEC tools designed for precise surface treatment….

Powertrain

Xebec Deburring Technologies offers the best cutting tool for a chamfer edge, guaranteed to eliminate secondary burrs….

Manufacturers and machine shops have a plethora of options for deburring and finishing metal parts. However, choosing the right option for your operations is key to meeting expectations for spec, quality, timing, tool wear, and more….

How to Optimize Performance and Maximize Tool Life of your Xebec Deburring & Finishing Brushes…

Knowing how to identify the type of burr produced helps in figuring out the best way to remove it. You can count on help from the deburring experts at Xebec Deburring Technologies….

Achieve specific Ra & high-quality finishes on your aerospace turbines and automate with Xebec ceramic fiber deburring and finishing tools….

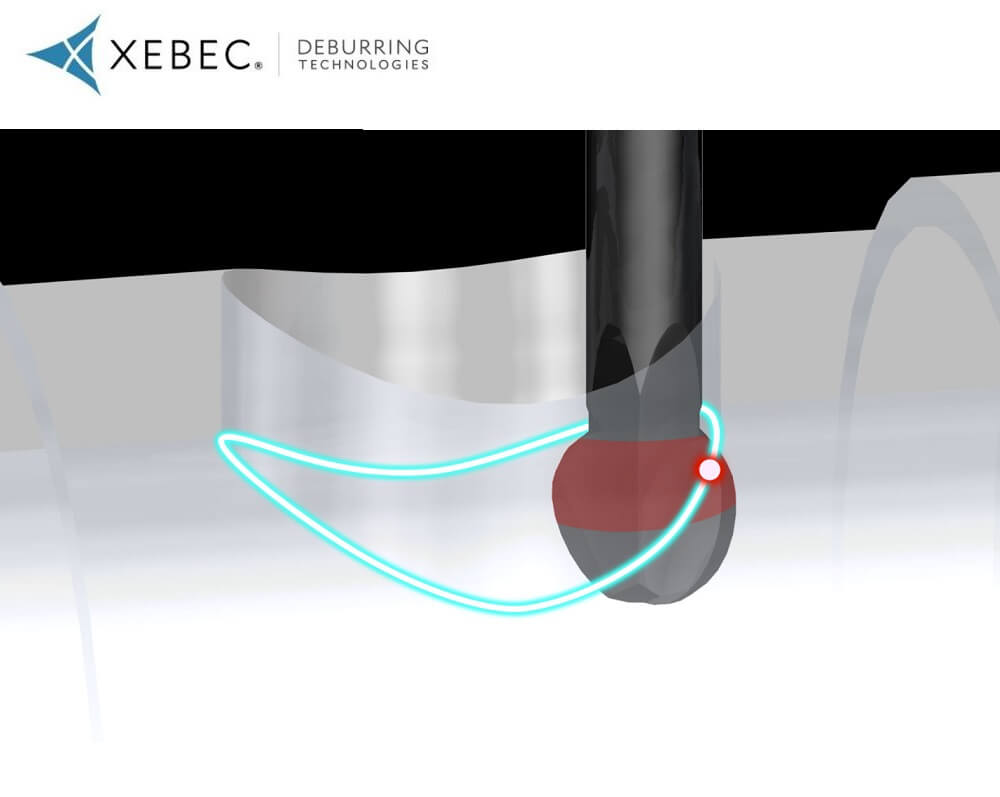

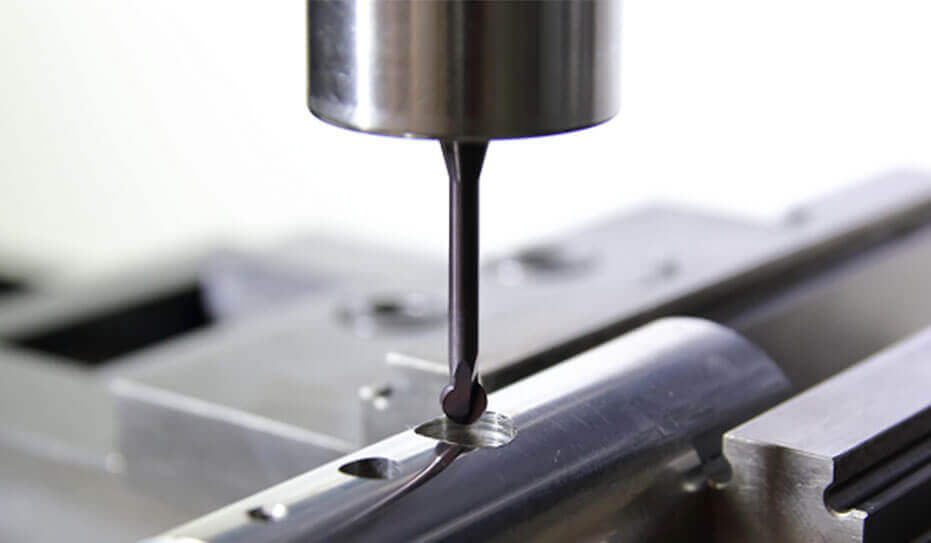

Xebec has back deburring of complex edge profiles, curved holes and 3D cross holes down to a science with ceramic fiber brushes for lights out manufacturing. …

Xebec has deburring and finishing down to a science – whether you need manual tools for detailed finishes or automated ceramic fiber brushes for lights out manufacturing. …

We’ve added another tool to our arsenal to help customers that need to deburr round parts, channeled diameters and deeper bores….

Imagine you’re a production supervisor tasked with the meticulous yet efficient deburring of parts with hundreds, thousands and even millions of holes. You know this is a monumental task if done manually….

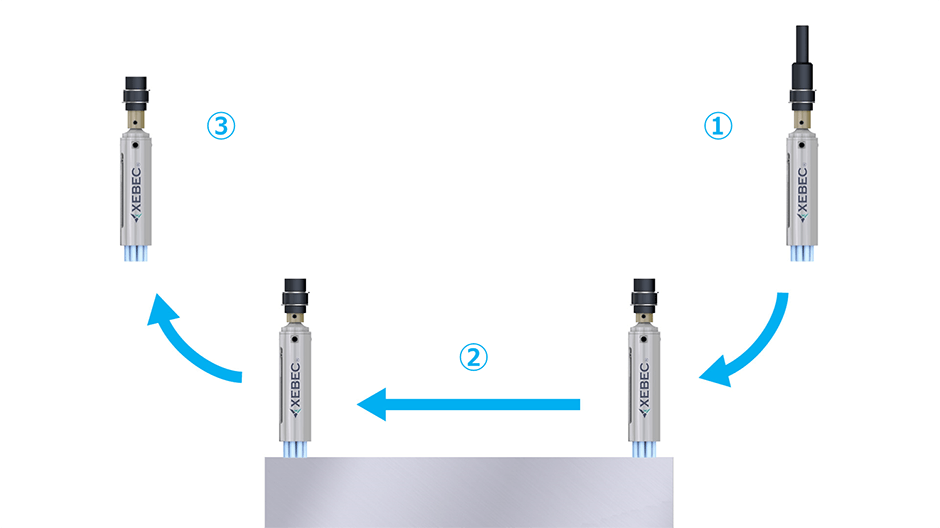

Though the Xebec® Brush Surface can be used by itself, pairing it with the Xebec Floating Holder has many benefits for the production line. Reduces machining time to adjust the depth of cut and the brush projection amount caused…

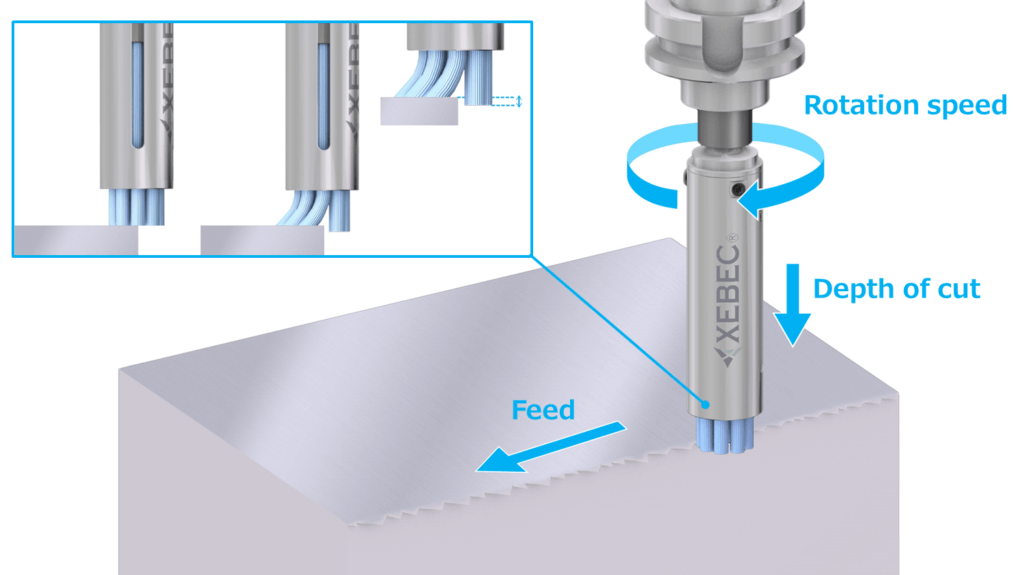

The Xebec Brush™ uses a unique abrasive ceramic fiber material instead of abrasive grain. Although it looks like a brush, it works like a cutting tool. Each bristle cuts from the tip to remove burrs and finish the surface….

Xebec Stone™ Flexible Shaft has grinding power on the entire surface of the head portion. The stone is formed from self-sharpening continuous ceramic fibers and mounted on a flexible shaft. It is available in ball and cylinder style heads….

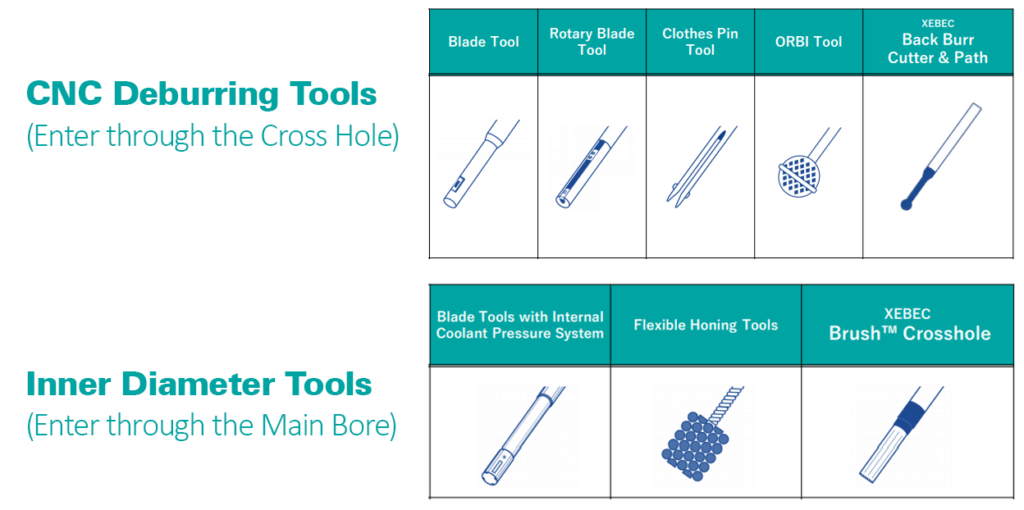

Burr removal can be tedious. Eliminating burrs on cross-drilled holes can be especially difficult. Which is why so many manufacturerers are looking to automate the process in CNC machines. There are many tools available and they generally fall into…

If you’ve just heard about Xebec, or have seen our website or social media pages, and you’re wondering – how are Xebec’s products different? Let’s take a look at how the ceramic fiber family of products and the Back…