If you’re not ready to automate deburring and finishing at your facility, you can still optimize your manual processes to save resources and improve outcomes. For instance, much better tooling options can transform the quality and profitability of your manual operations.

About your current process, ask yourself:

- How many manual tools and process phases does it take to finish the part?

- Are those tools cobbled together or designed for the application?

- Do those tools frequently cause injury?

- Do you have issues with quality and consistency?

- Are your outcomes dependent on tool wear, tool design and who’s doing the work?

That’s a lot of questions for a process that could be made simpler and more efficient with quality tools, such as Xebec’s selection of manual deburring and finishing tools. Using better tools that are designed for the task at hand will improve consistency, quality, timing and safety. It will reduce the number of tools and phases you need to finish a part, saving on costs and other resources.

The Problem with Handmade Tools and Other Alternatives

If your employees are designing their own hand-deburring and -finishing tools when they come to work in the morning, you likely have issues with consistency and safety. Consider the dangers of attaching a handmade tool to a drill. Anything that’s specifically designed for the task will be an upgrade from sandpaper on a stick, picks, X-ACTO knives and repurposed kitchen tools.

And even low-cost hand-deburring tools made for detail finishing have their issues.

- They have a short tool life.

- Their components may come loose.

- They’ll wear away quickly and some even break apart.

- The abrasives build up as they’re used, so you’ll have to work harder as they build up to achieve consistency.

- They tend to necessitate multiple tools and phases to achieve the appropriate Ra.

With more advanced hand-deburring tools from Xebec, like the popular Xebec Stone Flexible Shaft, you’ll get tools that:

- Xebec’s self-sharpening continuous ceramic fiber tools last longer and perform better than abrasives and other alternatives.

- Are more controllable, durable and consistent. The grit and grade of the ceramic fiber are dependable from start to finish, so you can duplicate the process easily and achieve repeatable results. And the ceramic fiber won’t leave or imbed residue on the finish.

- Can drastically reduce the number of tools and phases you need for detail finishing. Often, you can cut out several phases and take the part all the way to the required Ra with just one or two Xebec tools.

- Require fewer tool changes due to the reduced number of tools, meaning faster processes and less chance of dropping and losing parts and tools during transitions.

- Are more user-friendly, which is critical at a time when skilled labor is hard to find. Such user-friendliness can reduce instances of damage, scrap and injury.

An added bonus? Xebec tools can be dressed – also known as truing. For example, if you need the three millimeters to be a point, you can dress it down to a point. And if your tool gets damaged, you can easily fix it by dressing it.

Expertly Designed Manual Deburring and Finishing Tools

Xebec’s detail finishing tools are made from continuous ceramic fiber, which makes them more durable and gives them greater grinding power. They can be used to handle a variety of different materials, they don’t generate secondary burrs, and they improve surface roughness.

For example, these tools work with aluminum, stainless steel, titanium, Inconel, PPS (polyphenyline sulfide, a thermoplastic) and more. See the following video for a demo of several handheld deburring solutions from Xebec.

However, applying these tools isn’t cut-and-dry. They perform more like cutting tools – just as Xebec’s ceramic fiber brushes do in CNC machining – and it’s important to choose the right tool for the application. Often, a little insight from one of our application experts goes a long way in optimizing processes.

Are you using the best deburring method for the job? >>

Xebec Stone Flexible Shaft

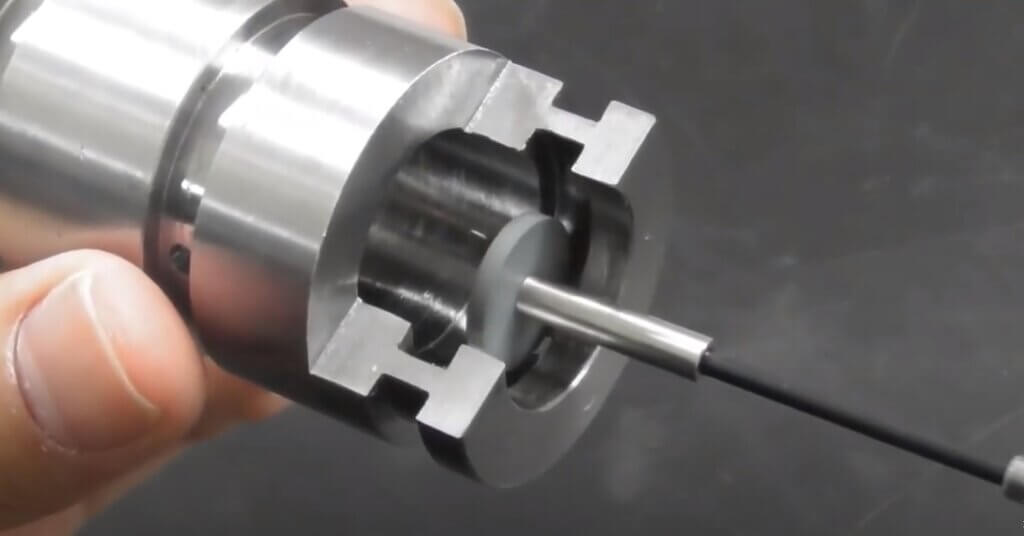

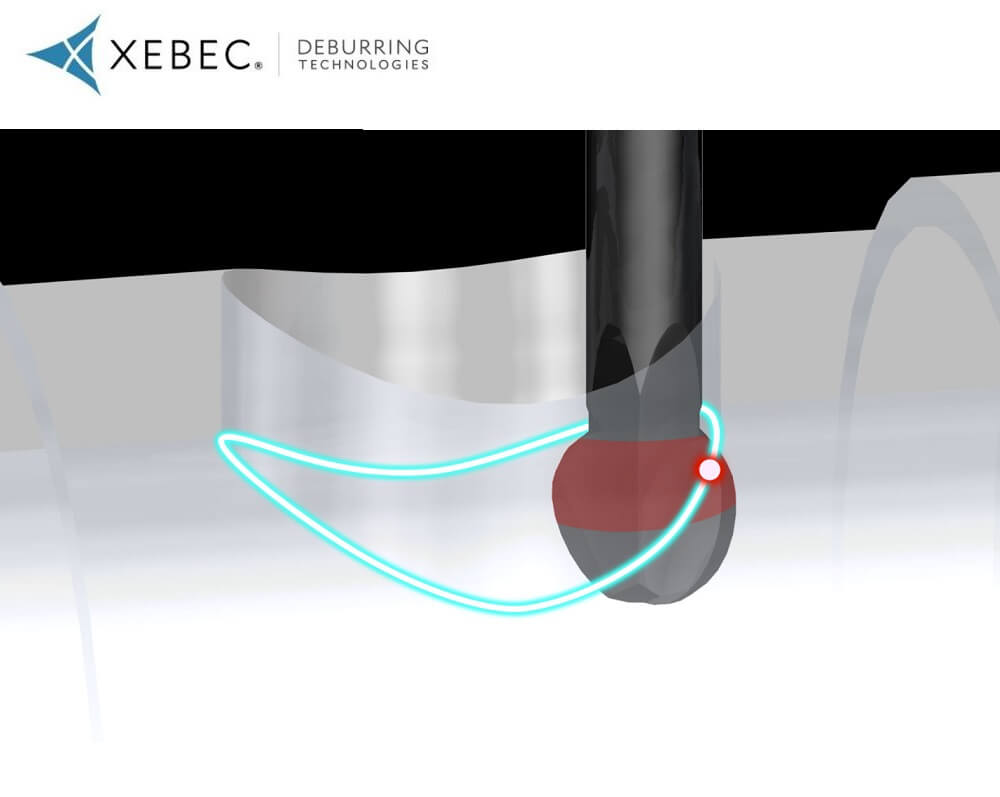

The Xebec Stone Flexible Shaft has a self-sharpening ceramic fiber stone which cuts on all surfaces. It’s ideal for deburring cross-holes and detail finishing. It’s a favorite across industries because the flexible shaft allows for soft contact with the workpiece.

This tool comes in three types: Ball, Cylinder and Disc. It can be used in an electric rotary tool, but it can also be automated in machines and robots. The stone is available in grits #800 (blue, least aggressive), #400 (orange) and #200 (gray, most aggressive).

These tools are popular in the aerospace and medical industries because of the finish they can achieve and the flexibility of the shaft, which allows them to follow a contour without picking up a secondary burr or gouging a part.

Xebec’s most popular detail finishing tool is the Xebec Stone Flexible Shaft Cylinder in Gray, which is a favorite for working aluminum because it doesn’t build up with aluminum during the process.

The Xebec Stone Flexible Shaft Disc Type is the newest of the three options. Xebec designed this tool to help customers deburr more challenging holes and parts, and it can be applied radially as well. The tool can be used for round parts, channeled diameters and deeper bores.

Examples of successful applications for these tools include:

- Deburring the edge of an iron-based spool after the end milling process (Production)

- Deburring inner and outer edges of elliptical holes of a stainless steel coronoid plate (Medical)

- Cross-hole deburring a carbon steel crankshaft cross-hole after drilling process (Powertrain)

- Deburring inner and outer edges of holes and channels of an aluminum alloy hand guard (Firearms)

- Deburring inner and outer edges of holes of an aluminum alloy shaft collar (Energy)

Get the Xebec Stone Flexible Shaft Instruction Manual >>

Xebec Brush End Type

The Xebec Brush End Type has the self-sharping action on the cutting edge of the ceramic fiber tips of the brush. It is ideal for cutter-mark removal, polishing and finishing parts with narrow features.

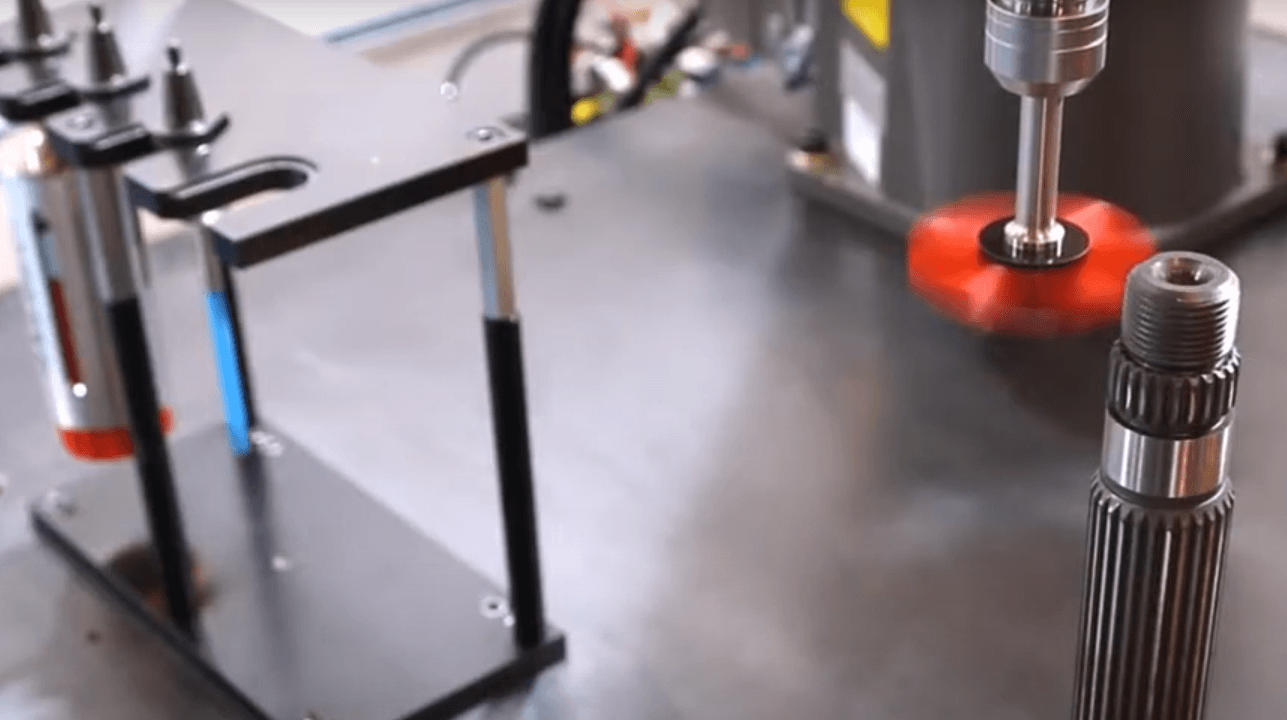

This tool is used across industries, including aerospace and firearms. It’s handy for getting into small spaces that are difficult to get into otherwise. It can be used with a rotary tool for manual finishing or automated in CNCs and robots.

It’s available in aggressiveness levels of pink, red, white and blue. Pink is least aggressive and can work materials like plastic or aluminum; blue is the most aggressive and can be used with stainless steel, Inconel and harder materials.

Examples of successful applications for these tools include:

- Deburring and finishing surfaces and edges of a cobalt chromium dental screw (Medical)

- Deburring and finishing of curved surface features and radial edges of a Hastelloy engine compressor shaft (Aerospace)

- Fine surface finishing and polishing of milled surfaces and deburring of polished edges of a stainless steel handgun frame (Firearms)

Get the Xebec Brush End Type Instruction Manual >>

Xebec Stone Mounted Point

The Xebec Stone Mounted Point has cutting power on the entire surface of its head. It is ideal for use with pneumatic tools at a high rotational speed. It can also be used in electric rotary tools.

You have three style options with this tool: Cylinder Shaft, Solid Cylinder and Pointed Tip.

The stone only comes in gray, with an aggressive #220 grit. The stone can also be dressed to different shapes to suit your application.

Get the Xebec Stone Mounted Point Instruction Manual >>

Xebec Ceramic Stone Meister Finish

Xebec Ceramic Stone Meister Finish tools are versatile tools for finishing parts by hand. They come in several styles, including:

- Rod Type: Ceramic fiber stone exposed on entire surface, meaning the entire surface has grinding power. Available in diamond.

- Stick Type: Tip-cutting ceramic fiber stone. Available in heat-resistant and diamond.

- Pencil Type: Small diameter for finely detailed work. Ideal for polishing narrow and thin parts.

These tools can be formed and shaped. They can be used by hand, either in your hand or with Xebec’s Stick Holder, Rod Holder or Pencil Holder. They can also be used in an electric rotary (such as the Xebec Mobile Micro Motor), ultrasonic polisher, pneumatic rotary or by hand. They work incredibly well in the mold and die industry.

These tools come in a broad range of grits, from red at #1200 to violet at #120.

*The diamond tools are side- and edge-cutting. Diamond has a different aggressiveness scale.

Get the Xebec Ceramic Stone Meister Finish Instruction Manual >>

Powering a Hand-Deburring Tool

Depending on the application and tool, you have a range of options for hand-tools, from ultrasonics to pneumatic rotaries to simply working by hand. Xebec has several sophisticated tools for these purposes, including holders for the meister sticks, rods and fine tipped pencil styles.

For powering a hand-deburring tool, the Xebec Micro Motor is an easy-to-use, portable, battery-powered rotary tool. It can be used with the End Type, Meister Rods, Flexible Shaft and Mounted Point. It’s lightweight, with a digital RPM display and strong torque to allow Xebec tools to cut freely under load. It comes with a 3mm collet, but a 2.3mm is also available.

Manual or Automated, Tooling Always Makes a Difference

At Xebec, we’ve helped manufacturers and machine shops implement these more advanced hand-deburring tools and:

- Reduce the number of tools they need, even from 15 down to two.

- Improve consistency and quality in their production.

- Reduce tool changes to save time and reduce risks.

- Improve safety on their shop floors.

- Save money on throw-away tools, damage and scrap.

If you’re having issues with manual deburring at your facility, get in touch with one of our application experts. Whether you’re looking to improve hand-deburring and -finishing or if you’re ready to embrace the future and automate these processes altogether, it’s best to do so alongside our professionals, who’ve worked with many others facing similar challenges.

2 thoughts on “Hand-Deburring Done Right: Selecting the Right Tools”

I would like to know more about application of mounted Ceramic fiber brush and mounted solid ceramic stones for surface finishing/ polishing on CNC machines itself. Please share more details as we have many such applications and customers interesting in these solutions.

Hello Naveen,

Here you can see some examples of the End Type Brush used in a CNC. And you can see a few using the Flexible Shaft Stone

Contact our Application Specialist at [email protected] if you want to discuss your application.