Did you know? Xebec brushes deliver the consistency, accuracy, quality and production speed that manufacturers seek in their deburring and surface finishing operations in one step. Our unique, patented ceramic fiber brushes outperform traditional technologies. Xebec will deliver enhanced precision and efficiency resulting in time savings and consistent workpieces. Use Xebec brushes in CNC machines, robotics, or hand-held devices for a wide variety of industries, such as:

Aerospace, Outer Space, Automotive, Medical, Firearms and More:

- Surface deburring, finishing and polishing

- Cross-hole deburring and bore finishing

- Polishing of molds and other detailed parts

- Thread deburring

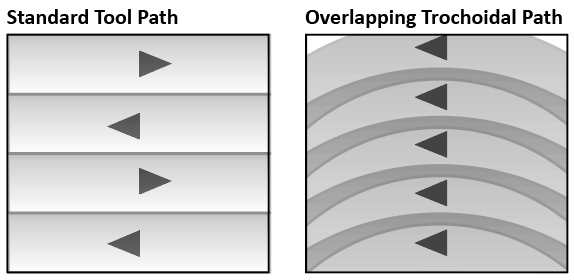

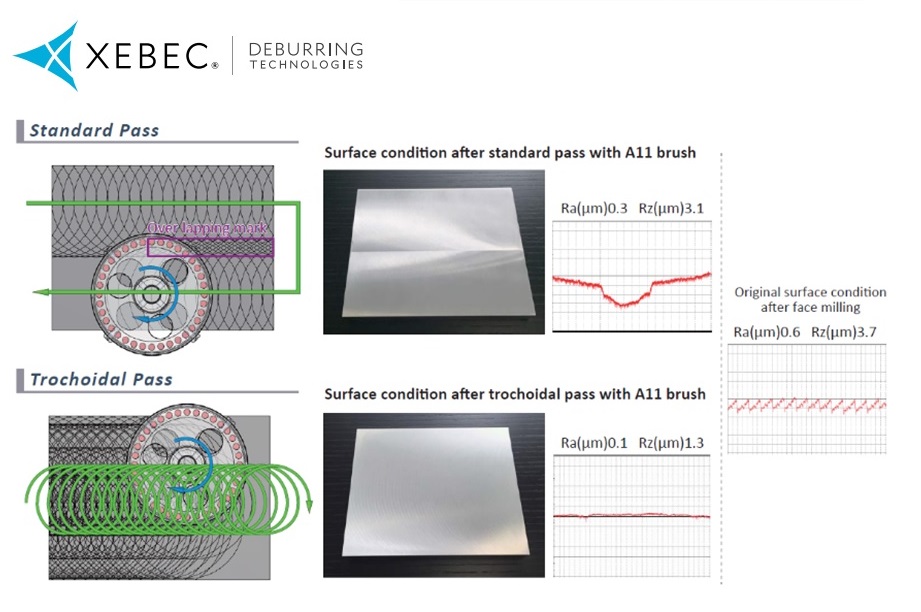

What about when you need to deburr or surface finish while leaving no machine tool marks? Traditional methods often result in step over or witness marks, leaving a less visually pleasing, finished part.

The solution? Trochoidal milling followed by Xebec finishing solutions.

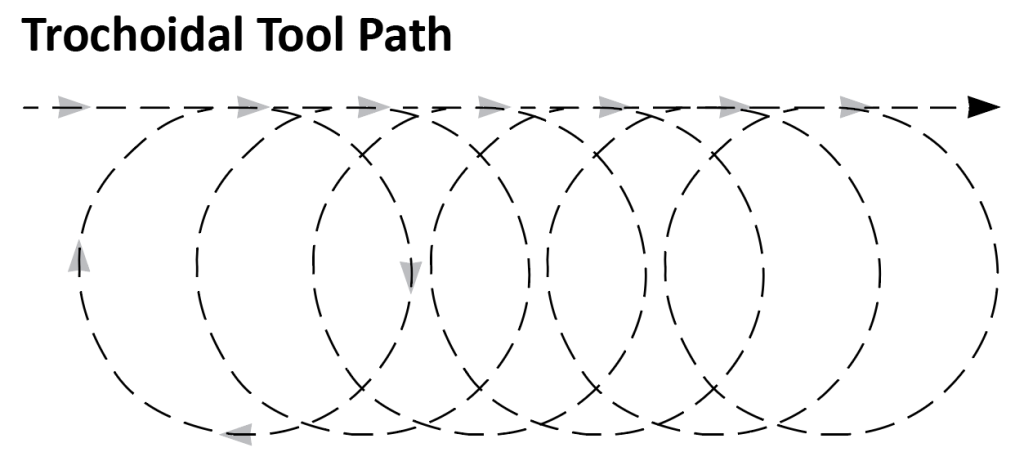

What is Trochoidal Milling?

Trochoidal milling is a method of machining that creates a slot that is wider than the cutting tool’s diameter. This is possible through a series of circular cuts known as a trochoidal tool path. This method requires specialized programming and machine tool capabilities. It involves using circular tool paths with a constantly changing radius, creating a “trochoidal” or spiral-like motion.

Trochoidal milling is a form of High-Efficiency Milling (HEM) that leverages high speeds while maintaining a low radial depth of cut (RDOC) and a high axial depth of cut (ADOC).

Why consider using trochoidal milling paths?

Trochoidal milling may be an ideal method if you are looking for a finished piece that has no witness marks. This will allow XEBEC brushes to remove tool marks at the same time preventing step over marks of the Xebec tools.

The benefits of trochoidal tool paths include:

- Enhanced surface finish

- Ra compliance

- Visual inspection

When are trochoidal tool paths ideal?

Trochoidal tool paths produce a smoother surface finish than other milling methods.

You can use trochoidal tool paths on a wide range of other materials, including metals like aluminum, steel, stainless steel and titanium along with non-metallic or heat-sensitive materials like aerospace alloys or superalloys, composite materials or non-ferrous materials.

Why Superior Surface Finishing is Critical in Manufacturing

Part performance is a critical component in your assembly, and surface finishing ensures a proper and secure seal between parts. It also ensures fluid and airflow with no interruptions. This can prevent catastrophic failures in critical components in aerospace, fluid power, medical, automotive, firearms and energy industries. Providing parts with to-spec surface finishing requirements is what Xebec solutions do best.

“Can you remove tool marks?”

Yes, we can. Beyond function alone, many manufacturers have begun to prioritize the “look” of the part to meet customers’ aesthetic expectations. In some instances, customers have rejected parts if the visual inspection fails, even if all surface finish criteria have been met.

The manufacturer may then try to create the desired surface with their current finishing methods. However, this often resulting in inconsistent results and irregularity.

Instead, we recommend surface finishing with Xebec for the following results:

- Improved surface finish – both visually and functionally.

- Consistent results that are to spec.

- Faster finishing process than manual or automated alternatives.

- Consolidation of deburring and finishing, reducing wasted tools and time.

- Opportunities to reallocate labor more effectively.

Xebec Brushes Meets the Demands of Hi-Tech Industries

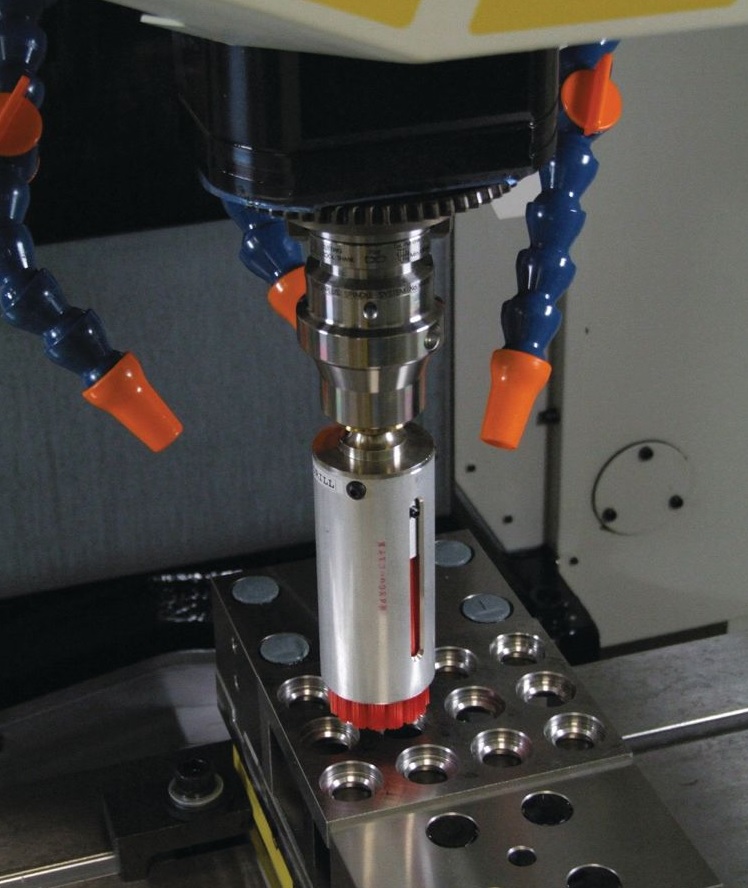

Xebec brushes work beautifully with trochoidal milling process.

The Xebec brush can be programmed to go in a circular motion in the trochoidal tool path and step over (versus just linear passes back and forth). When the clients use trochoidal milling methods with Xebec brushes, the result will be a beveled edge without step-over or tool marks.

Xebec brushes perform like a cutting tool due to its patented ceramic fiber construction.

Ceramic fiber brushes perform more like cutting tools than brushes. Speeds, feeds and depth-of-cut matter when using Xebec brushes. They are designed to hold shape, self-sharpen and create consistency. Even machine shops with a small volume of deburring projects see benefits in cost and productivity with Xebec tools.

Xebec brushes deburr and finish your components to tight surface roughness specifications.

The Xebec team works with top-tier, high-tech industries, such as component manufacturers for Outer Space, Aerospace, and EV and Hybrid vehicles, to develop tools and processes that meet these stringent quality demands.

Xebec has a variety of tools to meet the needs of high quality, tight tolerance, precision driven manufacturing. Xebec is available in sizes ranging from 1mm to 200mm.

>> Burr Basics: Identifying Burr Types to Efficiently Remove

Xebec brushes can deburr and finish a wide variety of metals and other materials.

Most materials generate burrs during production, whether from milling, drilling, cutting or otherwise. These burrs have the potential to be catastrophic when used in specific applications (i.e., knee replacements or flanges used in oil and gas). Maybe you’re working on high-end sports equipment and need quality tools that can tackle the materials you’re using. Rather than be limited to the materials you can tackle in production, you need solutions that work with a broad variety of workpiece materials.

Xebec products can handle a wide range of materials (up to 65 HRC), including:

- 304 Steel

- Titanium Alloys

- SCM (Carbon chromium molybdenum alloy steel)

- Aluminum Alloys

- Inconel

- Hastelloy

- Cobalt-Chromium Alloy

- Carbon Fiber

- Plastics, including PEEK and Nylon

- Tungsten

- Super Alloys, Exotic Metals and more

With the exception of cobalt and chrome, Xebec solutions don’t typically require an additional finishing step. Xebec tools will get you to the desired surface roughness on the machine but could require additional polishing for a mirror finishing aesthetic.

Whatever your needs, we have the technical expertise and experience to help you solve your deburring and surface finishing needs. See if Xebec brushes are right for you. Reach out to learn more and start a conversation with our knowledgeable team about your surface finish needs

Having the right deburring and surface finishing technology is critical to maintaining production rates without sacrificing quality standards.