Improve machine shop productivity by thread deburring with Xebec ceramic fiber brushes. Contact IPT America to learn about our thread deburring tools….

Automated Deburring

Automated XEBEC ceramic fiber brushes make deburring and polishing a one-step process….

Improve job costing and production at your CNC machining center by automating deburring and finishing with Xebec Deburring Technologies. For more info contact us at (800) 434-9775….

Invest in automated deburring and finishing tools by Xebec to improve metalworking safety and eliminate machine shop safety hazards….

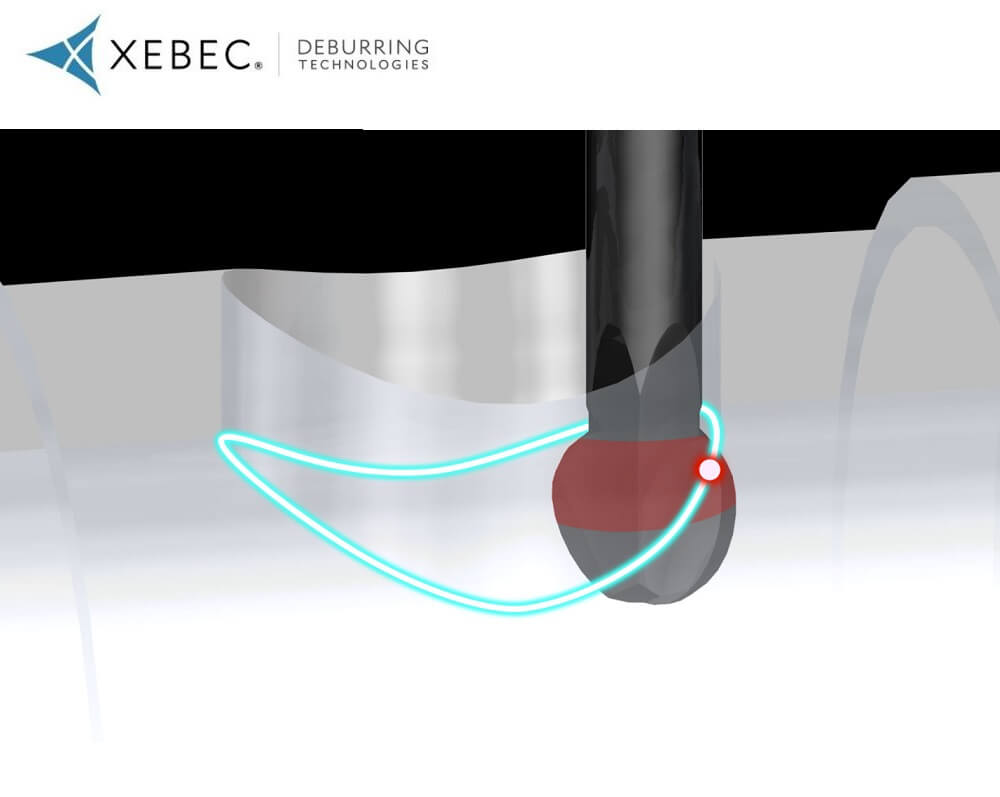

Xebec has back deburring of complex edge profiles, curved holes and 3D cross holes down to a science with ceramic fiber brushes for lights out manufacturing. …

Xebec has deburring and finishing down to a science and the right fixturing is critical for meeting client specifications and maintaining your reputation for excellence. …

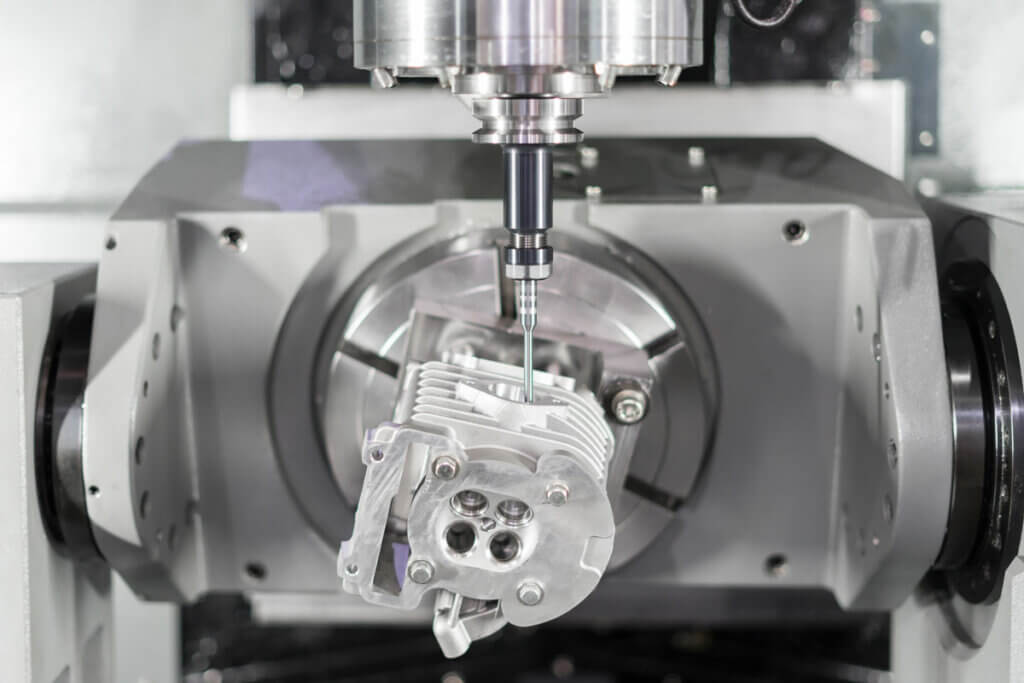

Done-in-one machining isn’t a new concept. But it’s also not the most common means of production, especially for smaller operations….

Yes, your CNC operation can actually be more productive by automating deburring inside the CNC and performing the tapping outside it. …

Xebec Deburring Technologies had the opportunity to publish an article in Cutting Tool Engineering magazine regarding automation in aerospace manufacturing. …

Tools that automate deburring and finishing are among those smart investments. In such an exacting industry, automating with the most effective, efficient tools available pays big dividends….

It’s easy to stay stuck on machine cycle time as a measure of efficiency. However, new, innovative tools are creating new opportunities to optimize net production time, and some of those opportunities actually add seconds or minutes on the…

Surface finishing is an important part of the manufacturing process. It involves removing or reshaping the material to achieve a specific surface roughness that ensures post-production performance and endurance. It is often the last step before a part is…

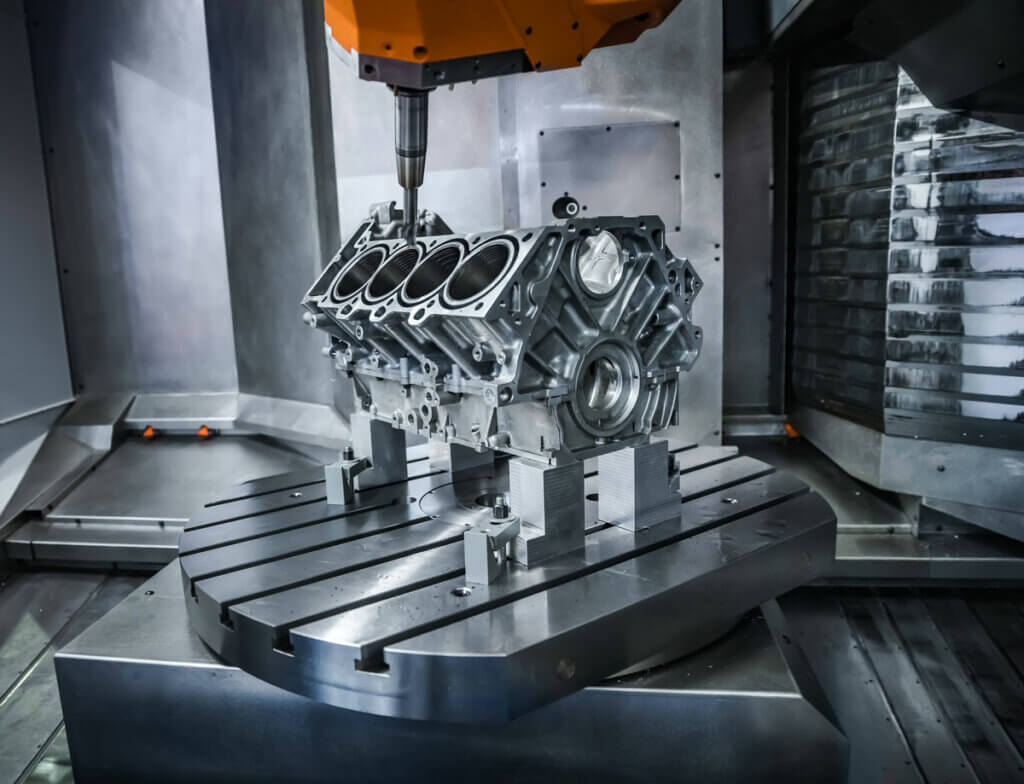

Joining the EV and HEV automotive market? High tech industries like aerospace use Xebec Deburring solutions to meet tight tolerances and increase production….

CNC machines are tried and true in metal machining and metalworking. They’re even more resourceful when manufacturers use them to automate deburring and finishing….

Deburring and finishing after-market parts in the firearms industry is typically a complex and tedious process. The detail of the work and the feel of the finish is incredibly important to maintaining a reputation for high quality, precision and…

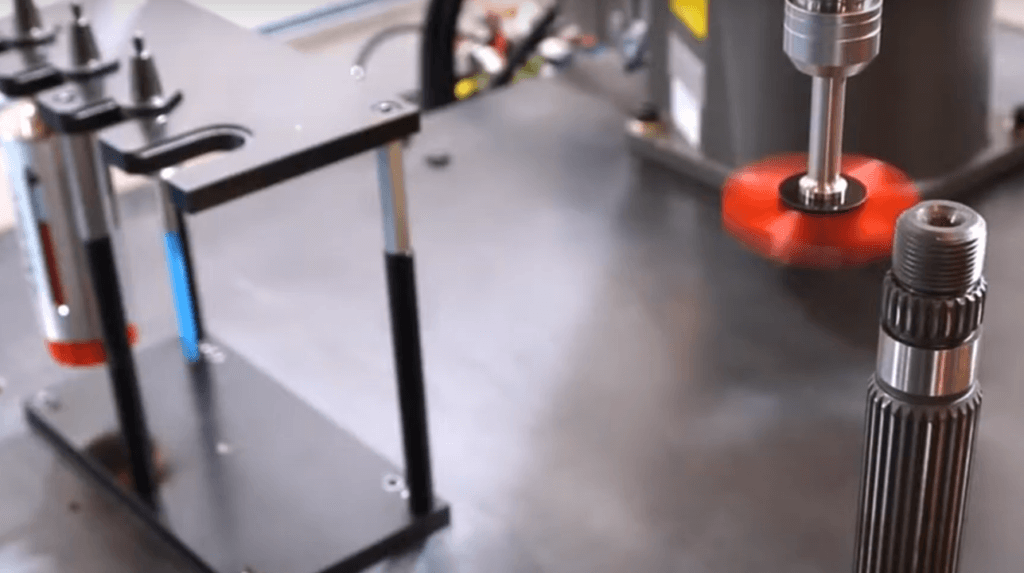

Though the Xebec® Brush Surface can be used by itself, pairing it with the Xebec Floating Holder has many benefits for the production line. Reduces machining time to adjust the depth of cut and the brush projection amount caused…

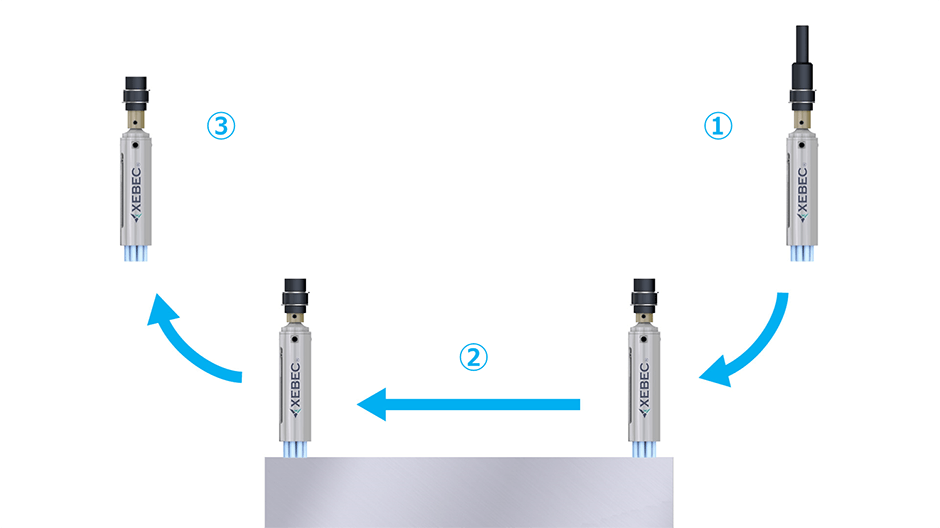

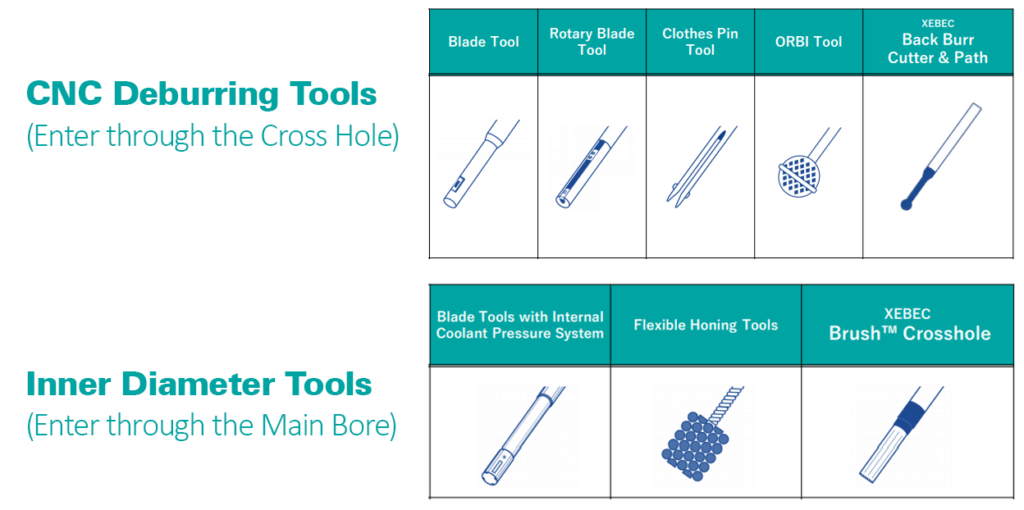

Burr removal can be tedious. Eliminating burrs on cross-drilled holes can be especially difficult. Which is why so many manufacturerers are looking to automate the process in CNC machines. There are many tools available and they generally fall into…