Deburring and finishing after-market parts in the firearms industry is typically a complex and tedious process. The detail of the work and the feel of the finish is incredibly important to maintaining a reputation for high quality, precision and performance.

Performing these steps manually creates issues with consistency, rework, scrap and worker injury. These are the clear flaws with the process. If performing deburring manually, you’ll discover you’re losing out on productivity and labor cost savings comparing your process to today’s more efficient and expedient methods.

Consider that, when demand spikes, you want to be able to meet that demand as efficiently as possible and cut back on unnecessary time spent – without diminishing quality.

The clear and hidden flaws of manual deburring include:

- Inconsistent results. Each employee engaged in manual deburring is likely to have their own process and tools for doing so. And they’ll have varied energy and attentiveness depending on day and time.

- Higher potential for injury. Working manually and closely to deburr and finish complex parts could easily lead to worker injury, such as direct cuts and fly-away metal.

- Extra labor cost. Manual deburring and finishing take time and attention, pulling employees away from other production tasks.

- Longer production time. Because it takes longer to perform these tasks manually, your time to a finished product is extended.

- Reduced productivity. With both your employees and your parts held up by manual processes, you’re limiting productivity across your operations.

- More rework and scrap. Manual work means greater potential for errors and quality issues, particularly with the complexity of firearm parts and the expectations for precision and performance. You could end up regularly scrapping or reworking expensive parts, which affects your profitability and production schedule.

Xebec Deburring Solutions and Applications in the Firearms Industry

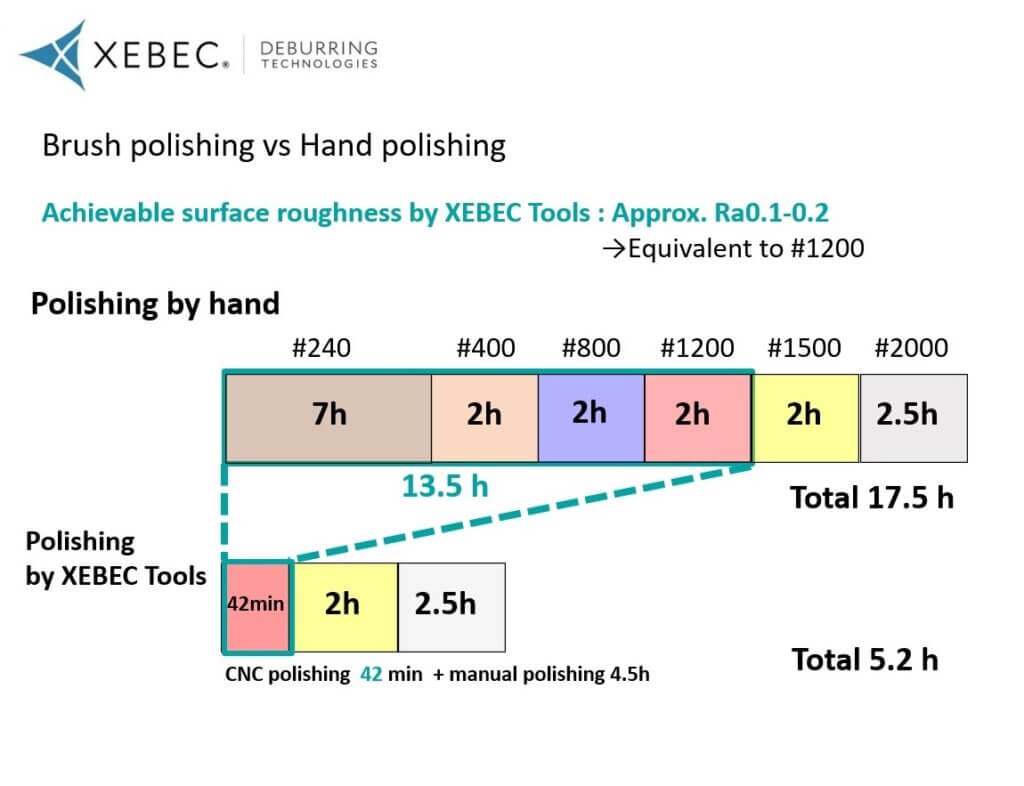

Xebec deburring solutions are ideal for performing both the deburring and finishing of many after-market firearms parts. With these tools, such as Xebec Ceramic Fiber brushes, you’ll achieve greater efficiency, cut down run time, and produce consistently high-quality, high-precision parts. Here are a few ways Xebec tools are applied in the firearms industry:

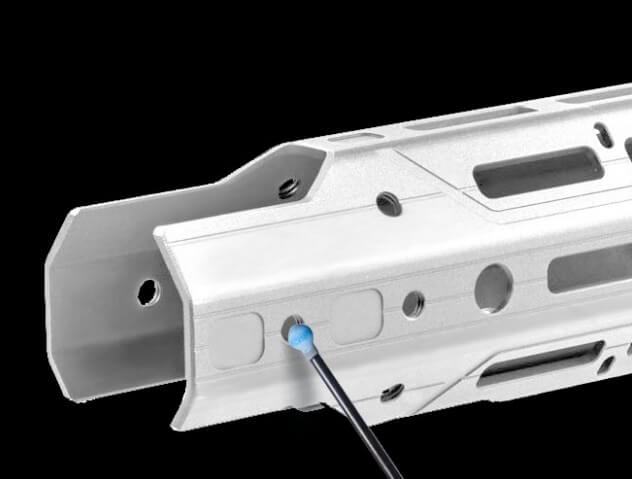

Xebec Surface Brush: Can be used to deburr edge radiuses and finish the edges of stainless-steel trigger assemblies and aluminum alloy rifle rails.

Xebec Back Burr Cutter & Path: Can be used to deburr and chamfer multiple holes in a single pass on alloy lower receivers.

Xebec Crosshole Brush: Can be used to deburr the grooved inner wall diameter of a stainless steel revolver cylinders and access the smallest openings.

Xebec Wheel Brush: Can be used to deburr the muzzle threads on any threaded barrel allowing for easy installation of any muzzle device.

Xebec Stone Flexible Shaft: Can be used to deburr the inner and outer edges of holes and channels on aluminum hand guards.

Xebec Brush End Type: Can be used for edge deburring, detailed fine surface finishing and polishing of aluminum or stainless steel handgun frames.

Xebec ceramic brushes paired with the latest technology can modernize your firearms deburring and finishing processes. See how quickly you can deburr a competition air rifle rail in this video made in collaboration with our partners: Ellison Technologies, Yaskawa, and Invictus Manufacturing:

How Xebec Saves Firearms Manufacturers Time and Money While Delivering High Quality

Firearm industry manufacturers could see substantial and immediate benefits using Xebec products in their processes.

Safer for employees

With automated deburring tools and more sophisticated, effective hand-deburring tools, you reduce opportunities for employee accidents and repetitive motion injuries.

More cost-effective

Xebec deburring tools save on costs associated with labor, scrap and rework by performing consistent quality deburring and finishing with every part. In one success story, a Xebec customer projected an expected savings of over $275k per year compared to their previous manual process.

Greater productivity

These tools deburr and finish parts faster and more efficiently, so you can potentially increase throughput. You can set up a Xebec integrated solution to operate 24/7 and significantly increase production. And employees who would otherwise manually deburr and finish parts can be more productive performing other revenue-generating tasks.

Better results

Xebec products will deliver more consistent finish and precise results than manual deburring efforts, which leads to satisfied customers and a reputation for quality in the firearms industry.

In one use case scenario using Xebec ceramic fiber brushes for automated deburring and surface finishing of an aluminum alloy air rifle part made by Invictus Manufacturing, used with a Yaskawa GP8 industrial robotic arm, the following benefits were realized:

- 10.75 minutes faster than deburring with powered hand tools

- Saved $4.31 per part making 80 parts per day, equates to $89,561 in annual savings