It’s easy to stay stuck on machine cycle time as a measure of efficiency. However, the innovative tools available today are shaking things up. They’re creating new opportunities to optimize net production time, and some of those opportunities actually add seconds or minutes on the machine.

If you’re keeping a close eye on CNC machine time, your first instinct may be to nix anything that adds to it. But when it comes to automated deburring and finishing, those seconds or minutes given on the machine could save you hours and even days in post-machining processes.

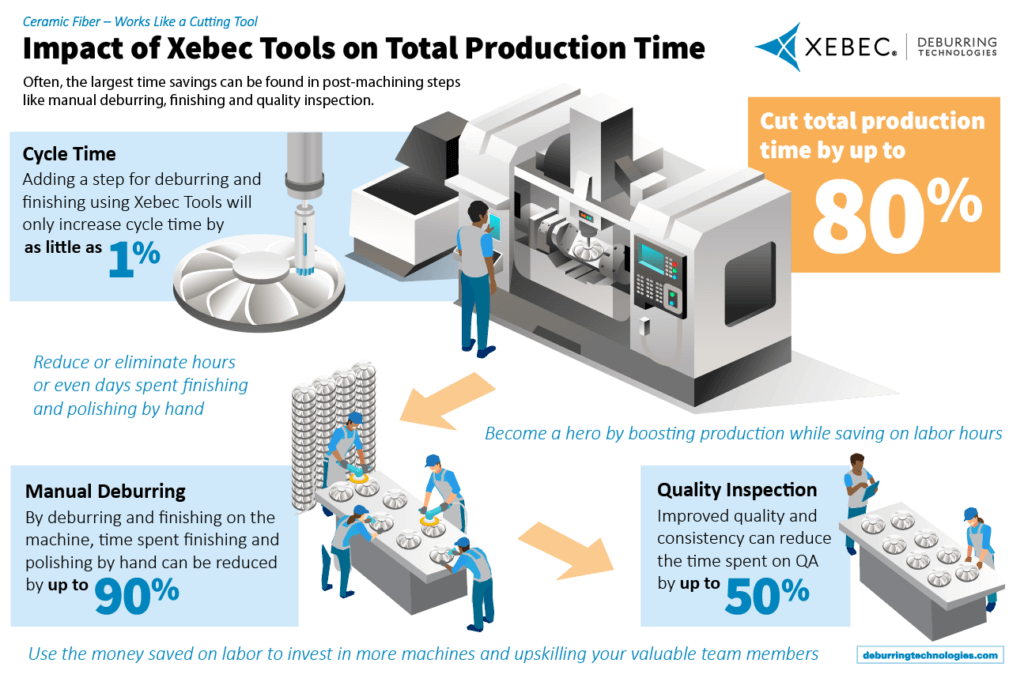

In fact, some of the largest time savings can be found in post-machining steps like manual deburring, finishing and quality inspection (QA).

It’s time to broaden your perspective to calculate total production time so you can make optimal investments toward efficiency, lean manufacturing and resource management.

Here, we’ll focus on the time savings you can achieve by automating deburring and finishing in your CNC machines. Automating these processes with quality tools will drastically shrink overall production time. For example, automated deburring and finishing with Xebec tools on the CNC machine will only increase cycle time by as little as 1%.

In turn, it will reduce time spent manually finishing and polishing by up to 90%. It will also improve part quality and consistency, reducing time spent on QA by as much as 50%.

The result? You could cut total production time by up to 80% – by adding as little as 1% to machine cycle time.

Note: If you’re already using a deburring tool in your CNC cycle time, Xebec solutions accomplish up to 60x faster than competitive products.

Calculate Overall Production Time – Make the Case for Automation

Would the time savings from automating deburring and finishing warrant the investment? To make the case, take a detailed look at the many factors that go into your existing processes. This will help you understand the current net production time per part. For instance, do you know the time spent per part for each of the following?

- Machine time

- Time spent adjusting and handling the part

- Time to manually deburr per expectations, which varies from person to person, day to day

- Potential unanticipated additional deburring

- Time to manually finish per expectations, which varies as well

- Potential unanticipated additional finishing

- Time to inspect

- Time spent reworking after failed inspection

- Time spent machining a new part to replace a scrapped part

- Potential time spent transporting parts to an outsourced deburring and finishing shop

Automating deburring and finishing adds to the first factor: machine time. But Xebec ceramic fiber brushes and other Xebec tools automated in a CNC machine have proven potential to reduce time spent in every other area. That’s because they’re lightyears faster than manual work, they work more like cutting tools than brushes and outperform impregnated nylon brushes, and they can deburr and finish at the same time on the machine.

>> Learn how much faster Xebec Back Burr Cutter with Xebec Path is than other cutting tools

Not only that, but the time savings and quality improvements you’ll realize with Xebec products translate to a better return on investment.

For example, the graphic below demonstrates time and labor savings specific to the deburring process realized by Xebec customers.

Actual Time Savings Realized Using Xebec Products

12-Hour Deburring Time Reduced to 15 Minutes

One customer automated deburring of the plate of an electronic part jig and reduced the process from 12 hours down to just 15 minutes. This reduced production time by 98%.

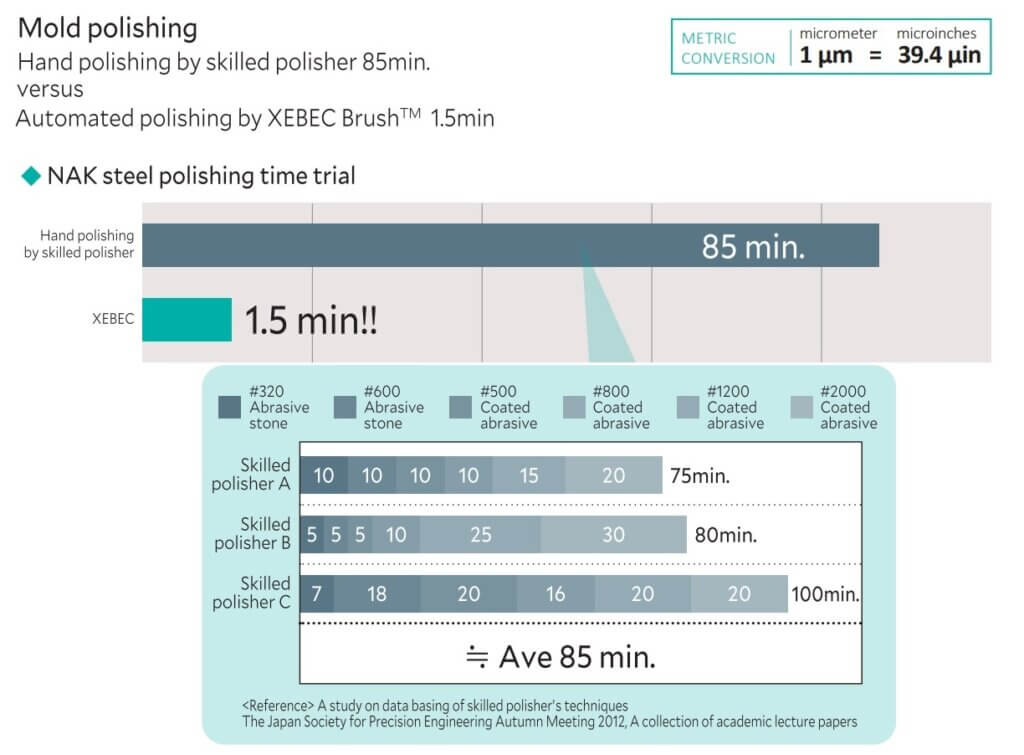

85 Minute Polishing Time Reduced to 1.5 Minutes

One customer automated a previously manual mold polishing process and successfully reduced the average time from 85 minutes to 1.5 minutes.

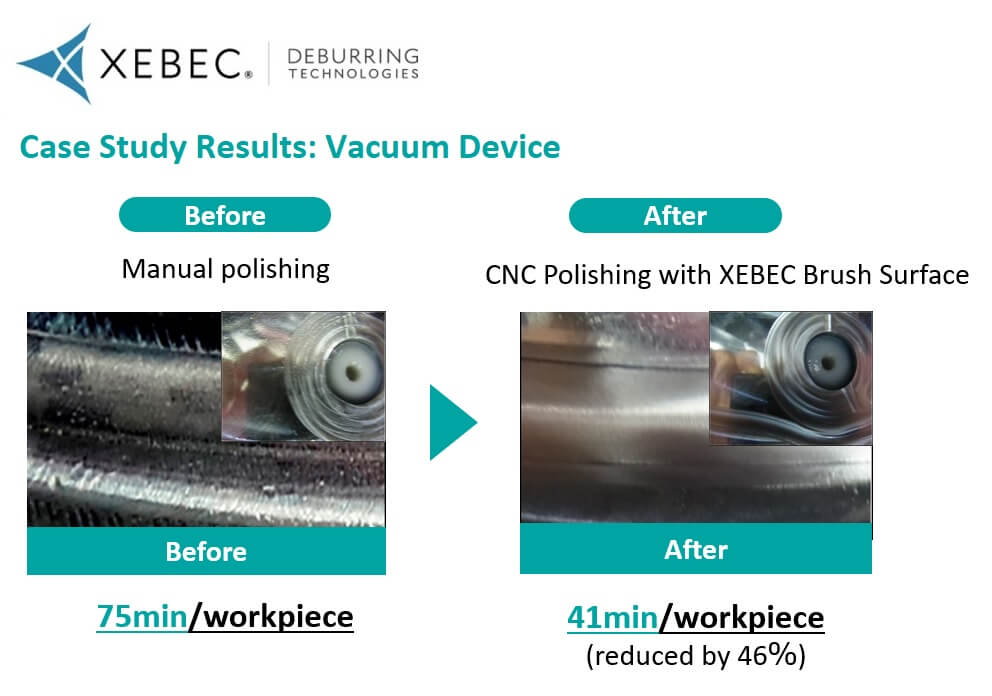

75 Minute Hand Polishing Time Reduced to 41 Minutes

Using a Xebec Surface Brush to do pre-polish surface finishing on a vacuum device in a CNC machine, previously all done by hand, reduced the time for manual polishing by 46%. Before introducing Xebec, manual polishing took 75 minutes per part and results were not consistent. After adding Xebec to the CNC step, the final manual polishing time was shortened to 41 minutes.

Realize Time Savings – and More – with Xebec

Xebec products do more than save time overall, particularly when compared to manual deburring and finishing. The fact of the matter is, manual deburring and finishing have regular quality issues, such as:

- Imprecise edge breaks

- Inconsistent deburring

- Inconsistent finishing

- More scrap and rework

- More quality control work

These issues add time, cost and headaches, and they restrict your ability to take on new work and maintain a reputation for quality. Automated deburring and finishing, on the other hand, means you’ll get high-quality results, consistently and in less time.

To learn more about the potential time savings in your production activities, reach out and get a conversation going with one of our experts.