There’s no question that component quality, finish and precision are critical in the aerospace industry. Many negative consequences could arise from integrating a part that isn’t deburred and finished to spec. Every part that goes into an aircraft, rocket or missile system, space launch vehicle or spacecraft must be of the highest quality. And to achieve that quality, it’s imperative to remove all burrs and deliver a finish that meets or exceeds specification.

The aerospace industry depends on precisely manufactured, durable and heat-resistant components to ensure safety, reliability and stability. With the rapid evolution of aerospace design, the challenges are many. Manufacturers are taking advantage of newer, lighter alloys such as lightweight aluminum, nickel-based superalloys and titanium superalloys to reduce weight and increase the operating temperature limit.

Also, more manufacturers are using additive manufacturing (AM) to quickly prototype parts and reduce the time to full production. In fact, NASA developed a new alloy (ODS-MEA) using additive manufacturing to enhance mechanical properties at extreme temperatures. NASA see many uses for this newly developed alloy in high-temperature components applications such as propulsion or space launch systems, and jet/marine/electricity-generating turbine engines.

These challenges mean that newer, automated processes of deburring and finishing, like Xebec’s automated deburring solutions, are essential to meet the strict quality demands of this industry. Consulting with Xebec reps from step one allows aerospace manufacturers to implement a process that ensures high quality components while increasing production.

Partnering with a company, like Xebec Deburring Technologies, which has extensive experience helping top tier spaceflight companies implement deburring and finishing processes, can help you meet these challenges.

>> Download our interactive guide for automated deburring solutions for aerospace

Xebec Deburring and Aerospace – The Critical Finishing Touch

Xebec products remove cutter marks and smooth out peaks and valleys to achieve critical Ra specifications and surface finishes. And Xebec does this with greater efficiency and consistency – and in significantly less time than other automated or manual processes.

With these processes automated, employees are relieved of hand deburring and much of the finishing. Manufacturers facing a shortage of skilled labor can automate the deburring and finishing process and avoid a slump in production.

Critical aerospace industry parts that require deburring and finishing land in many categories, including aerospace engine components, turbines, blisks, landing gear and engine parts, air- and spacecraft bodies, wings, and more.

For example, the Xebec Brush Surface can be applied to the following parts:

- Aircraft or Rocket Body

- Landing Gear Parts

- Blisk

- Turbine Blade

- Turbine Disk

- Wing Rib

- Engine Bracket

- Engine Shell Nozzle

- Engine Compressor Shaft

- Large Inner Diameter Pipe

- Threaded Diameter

- Pipe Fitting

- Pipe Part Crosshole

At Xebec Deburring Technologies, we understand how imperative it is to produce high quality parts or tools used in the aerospace industry. We understand your risks and challenges – and we take the matter of precision and safety as seriously as you and your partners do.

Critical Part Highlight: Parts with Crossholes for Aerospace

While all aerospace parts require high-quality finish results, parts that have cross-drilled holes and other difficult-to-access areas such as undercuts, grooves, slots or internal holes can be challenging. Manual deburring of the cross-drilled holes frequently found in engine components can be time consuming. The task is tiring and prone to injuries, and thus the quality over time can suffer.

Large companies can do this in-house and have rooms full of technicians who spend hours doing this tedious work. Smaller companies outsource the work and add the expense to the price of the part. Since cross-drilled holes often act as passageways for fluids, gases or lubricants in critical components, failure to remove all the burrs and sharp edges can cause blockages or restrict the flow. Residual burrs that end up in the fluid or gas can have negative consequences such as seal or engine failure. Burrs can also negatively affect dimensional tolerances, alignment and overall efficiency.

An automated deburring and finishing process that reduces hand work on the part, is of the highest quality and is fast, consistent and repeatable, especially for parts with cross-holes, gives manufacturers a leg up on their competition. Xebec offers several tools for the efficient and reliable deburring of parts with crossholes, such as engine brackets.

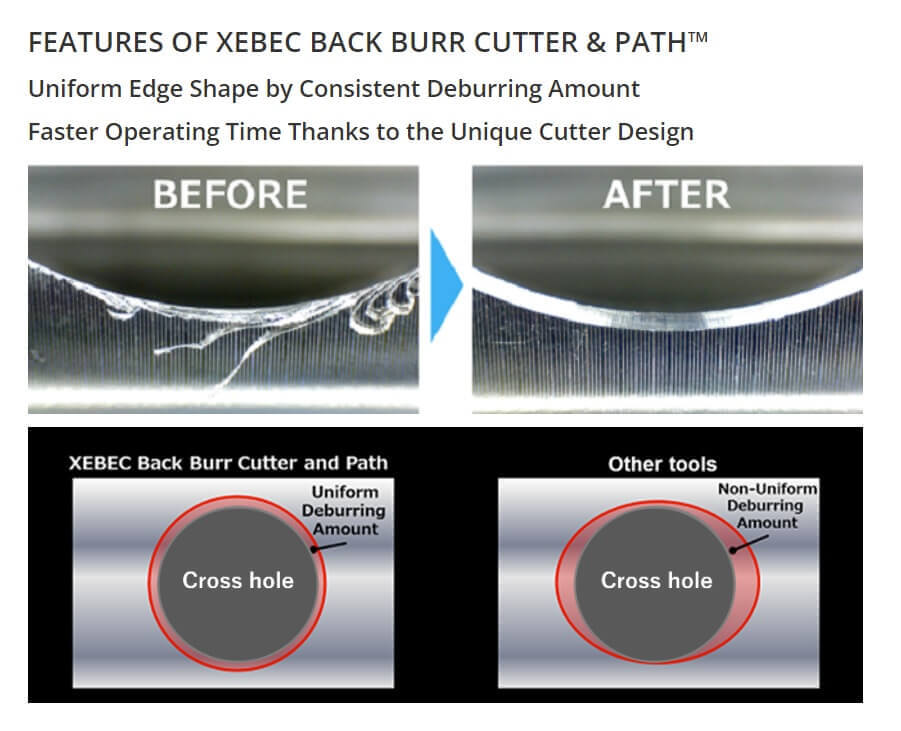

Xebec Product – Back Burr Cutter and Path™

An innovative CNC crosshole deburring solution, in combination with the spherical deburring cutter and the customized Path (NC data set), enables high-speed and high-precision deburring of 3D-curved crossholes. The Path is created specifically for the customer application, enabling deburring without secondary burr formation at the same time, freeing you from having to make your own program.

>> Read more on how the back burr cutter can help you create a consistent path to excellence.

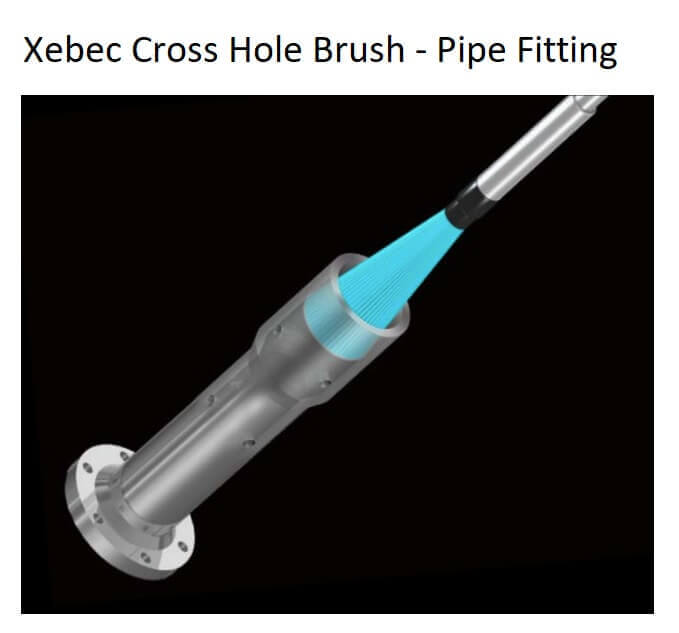

Xebec Product: Cross Hole Brush used to deburr a titanium alloy pipe fitting

The XEBEC Crosshole Brush™ has cutting edges that are made up from the tip of each fiber bristle, which create unsurpassed grinding power. When processing a crosshole, the brush rotates at high speed and expands by centrifugal force allowing for optimal deburring of crossholes.

Strategize to Excel in Aerospace Manufacturing

With a process that’s so consequential, aerospace manufacturers want to ensure they have a stellar reputation for reliable high-quality results. However, achieving this with manual deburring and finishing processes could see you incurring labor costs, scrap, rework and lost productivity. Set yourself up to meet the needs of cutting-edge aerospace companies and establish a process for producing superior parts so you’re the first company they call. Automate your deburring and finishing processes and watch your production and quality soar with Xebec Deburring Technologies.

Materials, tolerances, edge breaks and processes related to aerospace manufacturing aren’t new to us. We’re familiar with common metals used in the industry and can help you integrate automated deburring into newer processes such as robotics and additive manufacturing. We can work with complex parts, such as blisks and landing gear parts, and large components, such as engine shell nozzles and rocket bodies. And we can work with materials aside from metal alloys, such as PEEK plastic. We can help you not only remove burrs and achieve the right finish, but also make the process faster and more reliable, reduce setup time and tool changes, eliminate scrap and headaches, and enable you to reallocate your resources to improve productivity.

>> Watch how the speed of the Xebec Back Burr Cutter and Path demolishes the competition. Don’t blink or you’ll miss it!

For more information on how Xebec Deburring Technologies can help you increase the quality and production of your medical device manufacturing, contact us or give us a call at 800-434-9775.

2 thoughts on “No Burr Left Behind: Critical Parts in the Aerospace Industry”

What an impressive article! I love how you have listed the most critical parts and less-critical ones for a complete idea. Materials to be used must be light-weight and strive to improve fuel efficiency. They should also have a ‘tight tolerance’ and link accurately with other parts of the cargo planes or commercial flights.

Very helpful and educational blog. I had a great time with this event. I’ll let my friends know about this blog as well. Continue sharing.